Efficient punching device for mechanical part machining

A technology of mechanical parts and punching device, applied in the field of mechanical parts processing, can solve the problems of low processing efficiency, low safety, high risk of taking, and achieve the effect of fast clamping, fast feeding and punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

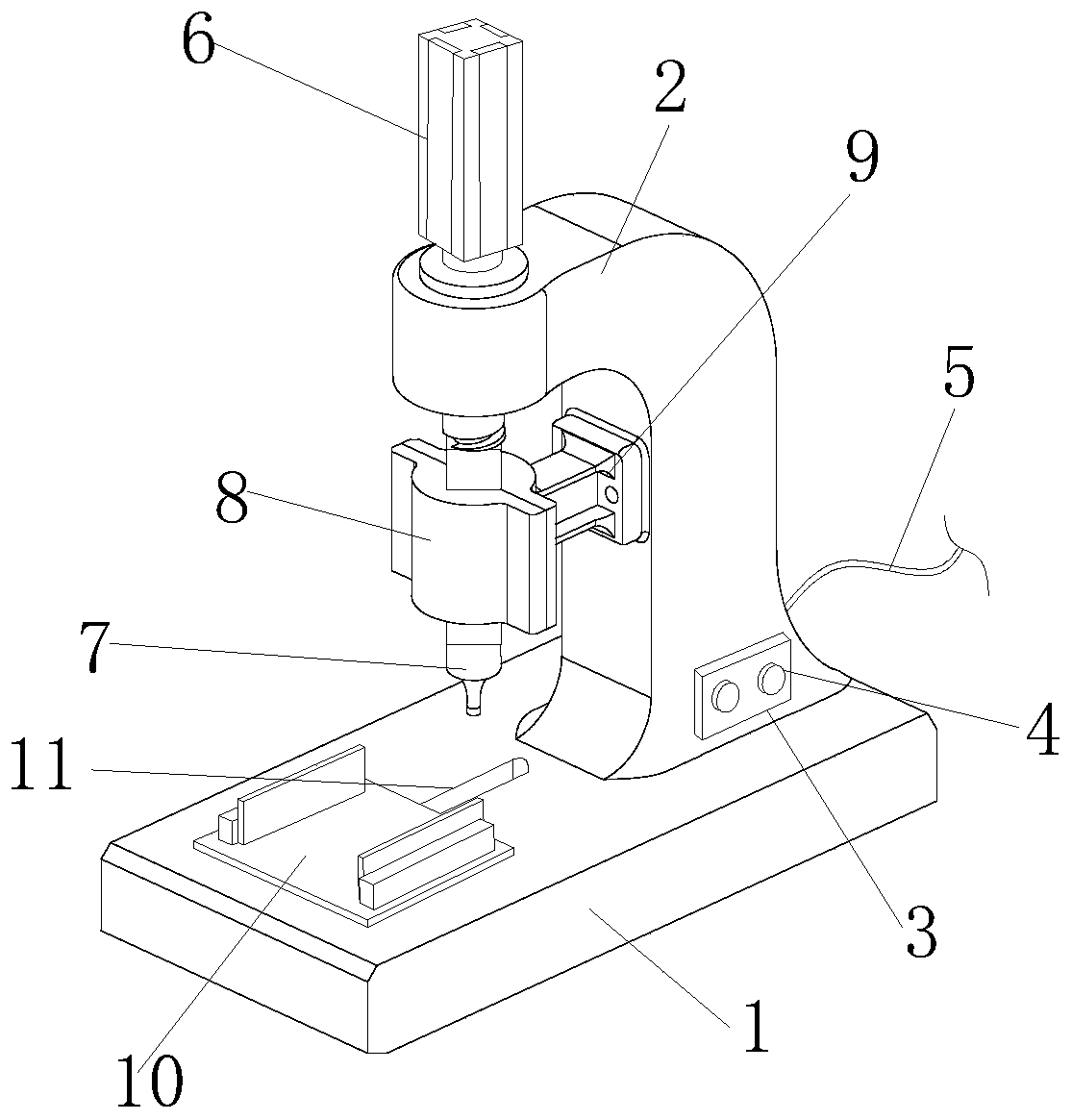

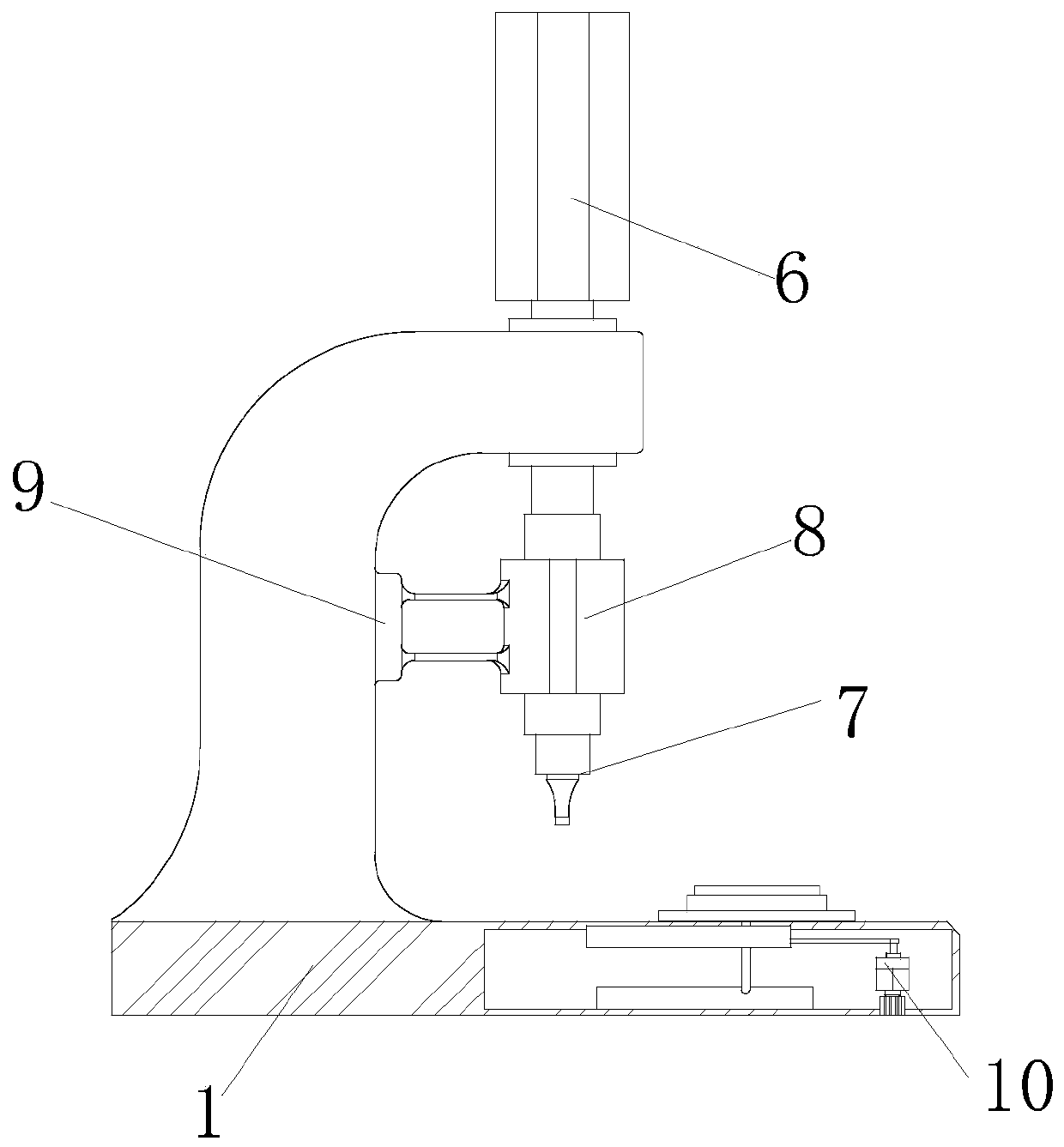

[0028] see figure 1 and figure 2 , the present invention provides a high-efficiency punching device for processing mechanical parts through improvement, including a base plate 1, an electric push rod 6, a punching head 7, a guide block 8, a support rod 9 and a reciprocating feeding mechanism 10, the base plate 1 and The bottom of the column 2 is fixed as a whole, the right end of the column 2 is provided with a control panel 3, the front end of the control panel 3 is equipped with a button 4, the rear end of the column 2 is fixed with a power wire 5, and the column 2 is locked and fixed with the bottom of the electric push rod 6 by screws, reciprocating The feeding mechanism 10 is installed and fixed on the inner right end of the bottom plate 1, the electric push rod 6 is fixedly connected with the top of the punching head 7, and the punching head 7 is slidingly matched with the inner side wall of the guide block 8, and the guide block 8 is fixedly connected with the front en...

Embodiment 2

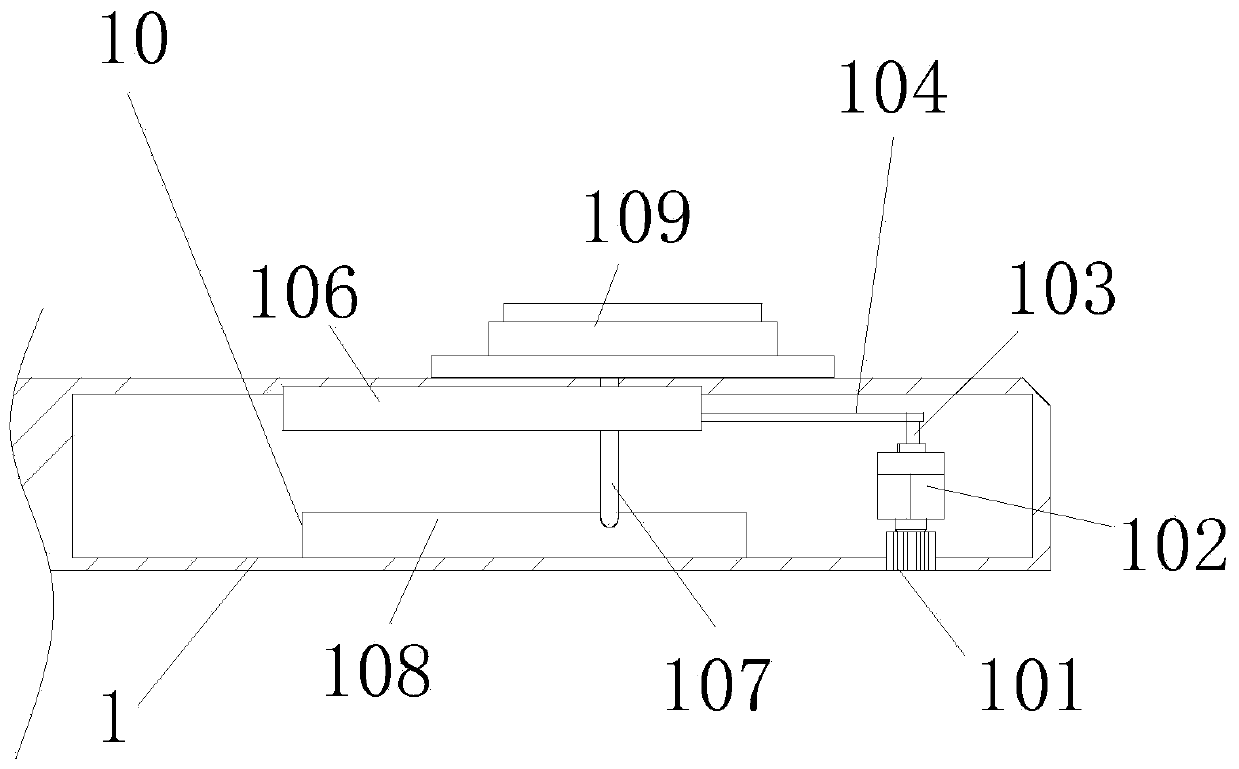

[0032] The present invention provides a high-efficiency punching device for machining mechanical parts through improvement. The sliding shaft 107 is in the shape of a cuboid, and the sliding shaft 107 runs through the left end of the sliding block 105 and the sliding frame 106, which is beneficial to drive the loading plate 1091 to carry out For smooth movement, the inner side of the fixed block 1092 is provided with a groove, and the clamp block 1094 is embedded in the groove inside the fixed block 1092, which is conducive to the smooth movement of the clamp block 1094. The inner side of the guide block 8 is cavity-shaped, and guides The inner wall of the block 8 is smooth, which is beneficial to make the punching head 7 move smoothly.

[0033] The present invention provides a high-efficiency punching device for processing mechanical parts through improvement, and its working principle is as follows;

[0034] First, before use, place the high-efficiency punching device for me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com