Up-conversion luminescence reversible control material and preparation method based on photochromic effect

A photochromic and effect technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems such as the performance is not too ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

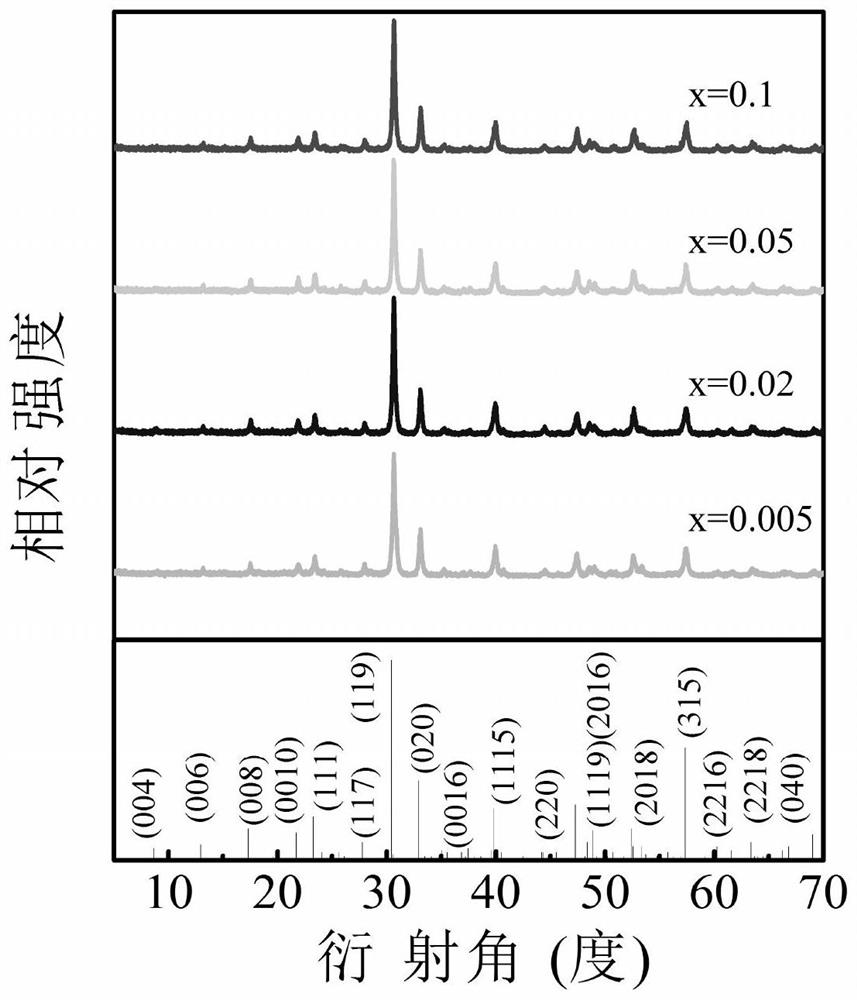

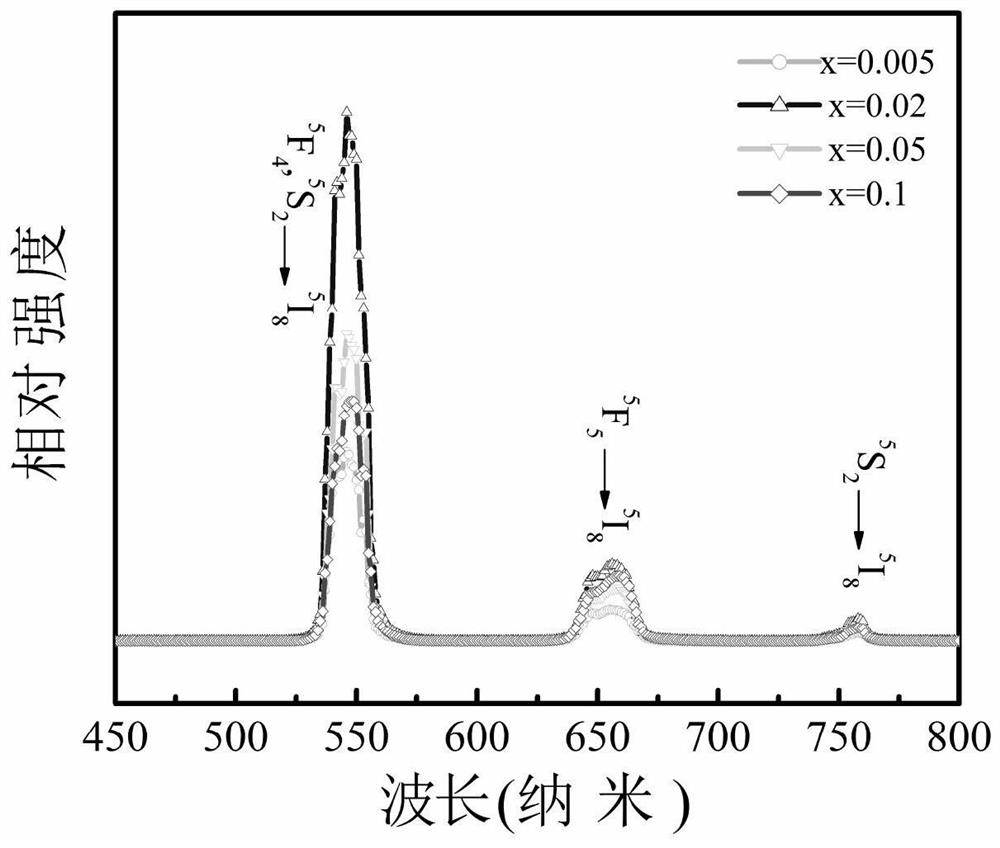

[0040] The upper conversion luminescence reversible regulatory material provided in this embodiment is SRBI 3.9-x HO x YB 0.1 Ti 4 O 15 Ceramic material, where x = 0.005, the preparation method is as follows:

[0041] Electronic balance of 0.0001 grams was used to weigh 0.8947 grams of carbonate (99%), 5.497 g of bismuth (99%), 0.1183 g of oxide (99.9%), 1.9362 g of titanium oxide (99%), 0.0057 grams of oxidation (99.9%), in a clean agate can, anhydrous ethanol (99.7%) of the can body was 2 / 3, and then placed in the planetary ball mill for 24 hours. The product was removed from the cannas can, placed in a glass beaker, drying with an oven, after grinding, placing the product into a rigory 坩 坩, put the box furnace, continuously warming up to 1050 ° C, 5 hours, cool down to 550 ° C. The resulting product obtained after the furnace was subjected to a agate mortar, and the adhesive polyvinyl butylaldate (PVB, 0.5% weight ratio was 0.5%), sufficiently ground, mixed uniform, and granula...

Embodiment 2

[0043] The upper conversion luminescence reversible regulatory material provided in this embodiment is SRBI 3.9-x HO x YB 0.1 Ti 4 O 15 Ceramic material, X = 0.02, the preparation method thereof is as follows:

[0044] Electronic balance of 0.0001 grams was used to measure 0.8947 grams of barbonate (99%), 5.4786 g of bismuth (99%), 0.1183 g of oxide (99.9%), 1.9362 g of titanium oxide (99%), 0.0227 grams of oxidation (99.9%), in a clean agate can, anhydrous ethanol (99.7%) of the can body was 2 / 3, and then placed in the planetary ball mill for 24 hours. The product was removed from the cannas can, placed in a glass beaker, drying with an oven, after grinding, placing the product into a rigory 坩 坩, put the box furnace, continuously warming up to 1050 ° C, 5 hours, cool down to 550 ° C. The product obtained after the furnace was subjected to a agate mortar, and the binder PVB was added (0.5% from the product weight ratio), sufficiently ground, mixed uniform, and granulated. A cerami...

Embodiment 3

[0046] The upper conversion luminescence reversible regulatory material provided in this embodiment is SRBI 3.9-x HO x YB 0.1 Ti 4 O 15 Ceramic material, where x = 0.05, its preparation method is as follows:

[0047] Electronic balance of 0.0001 grams of precision was used to weigh 0.8947 grams of carbonate (99%), 5.4362 g of bismuth (99%), 0.1183 grams of oxide (99.9%), 1.9362 g of titanium oxide (99%), 0.0567 grams of oxidation (99.9%), in a clean agate can, anhydrous ethanol (99.7%) of the can body was 2 / 3, and then placed in the planetary ball mill for 24 hours. The product was removed from the cannas can, placed in a glass beaker, drying with an oven, after grinding, placing the product into a rigory 坩 坩, put the box furnace, continuously warming up to 1050 ° C, 5 hours, cool down to 550 ° C. The product obtained after the furnace was subjected to a agate mortar, and the binder PVB was added (0.5% from the product weight ratio), sufficiently ground, mixed uniform, and granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com