Symbiotic layered perovskite material with reversible regulation and control performance and preparation method thereof

A perovskite material and layered technology, which is applied in the field of symbiotic layered perovskite materials and preparation, can solve the problems of limiting the practical application of materials, and the performance of inorganic photochromic materials is not ideal, so as to achieve good reversible control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

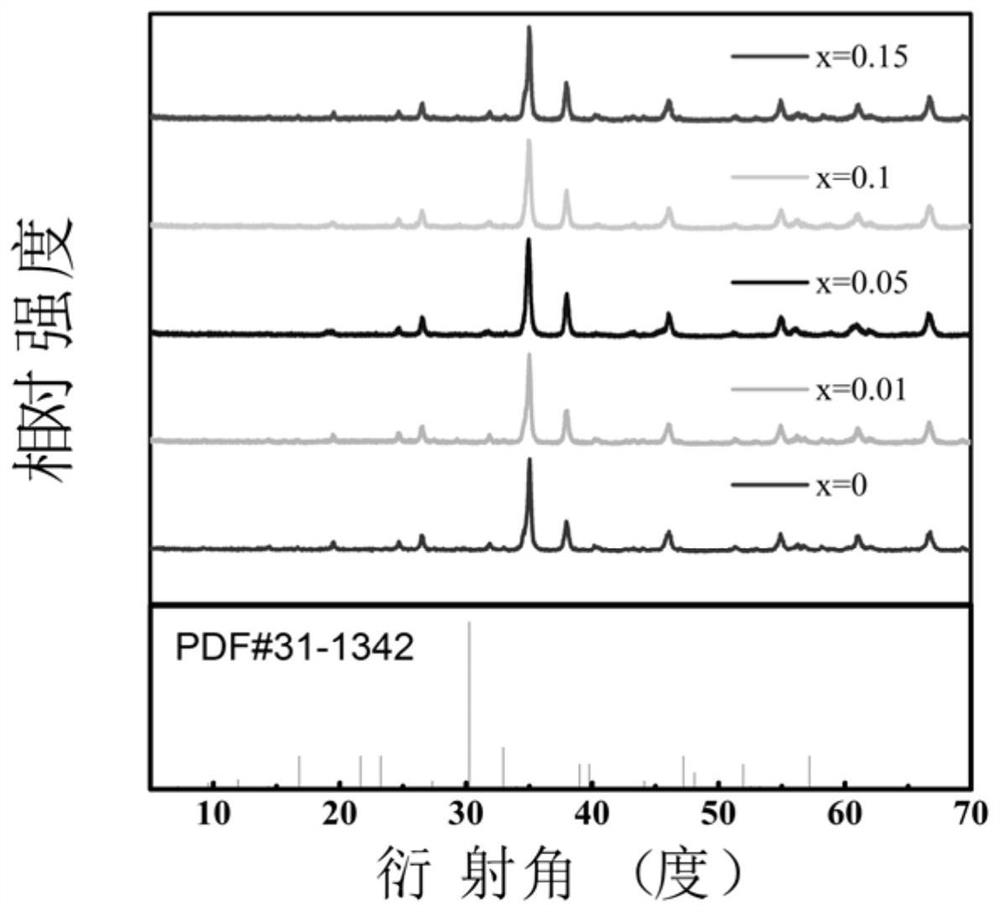

[0033]Prepare SrBi7.8-xErxYb0.2Ti7O27Ceramic material, where x=0, the preparation method is as follows:

[0034]Weigh 0.4474 grams of SrCO3, 5.6720 grams of Bi2O3, 0.1183 g Yb2O3, 1.6942 g TiO2Place it in a clean agate tank, use absolute ethanol (99.7%) as the medium, and mill on a planetary ball mill for 24 hours. The ball milled product is dried in an oven to obtain a dried powder. Grind the dried powder with an agate mortar, then place it in a corundum crucible, put it in a box furnace, continue to raise the temperature to 1100°C for pre-firing for 5 hours, and then stop the program after cooling to 550°C. The product obtained after cooling in the furnace was ground finely with an agate mortar, compressed into a disc with a diameter of 13mm by a tablet press, and then covered with alumina powder, placed on an alumina plate and sintered in the air at 1200°C for 1.5 hours, and finally obtained Flake SrBi7.8-xErxYb0.2Ti7O27Ceramic material.

Embodiment 2

[0036]Prepare SrBi7.8-xErxYb0.2Ti7O27Ceramic material, where x=0.01, the preparation method is as follows:

[0037]Weigh 0.4474 grams of SrCO3, 5.6647 grams of Bi2O3, 0.0057 g Er2O3, 0.1183 g Yb2O3, 1.6942 g TiO2Place it in a clean agate tank, use absolute ethanol (99.7%) as the medium, and mill on a planetary ball mill for 24 hours. The ball milled product is dried in an oven to obtain a dried powder. Grind the dried powder with an agate mortar, then place it in a corundum crucible, put it in a box furnace, continue to raise the temperature to 1100°C for pre-firing for 5 hours, and then stop the program after cooling to 550°C. The product obtained after cooling in the furnace was ground finely with an agate mortar, compressed into a disc with a diameter of 13mm by a tablet press, and then covered with alumina powder, placed on an alumina plate and calcined at 1200°C for 90 minutes in the air. Obtain flake SrBi7.8-xErxYb0.2Ti7O27Ceramic material.

Embodiment 3

[0039]Prepare SrBi7.8-xErxYb0.2Ti7O27Ceramic material, where x=0.05, the preparation method is as follows:

[0040]Weigh 0.4474 grams of SrCO3, 5.6356 grams of Bi2O3, 0.0287 g Er2O3, 0.1183 g Yb2O3, 1.6942 g TiO2Place it in a clean agate tank, use absolute ethanol (99.7%) as the medium, and mill on a planetary ball mill for 24 hours. The ball milled product is dried in an oven to obtain a dried powder. Grind the dried powder with an agate mortar, then place it in a corundum crucible, put it in a box furnace, continue to raise the temperature to 1100°C for pre-firing for 5 hours, and then stop the program after cooling to 550°C. The product obtained after cooling in the furnace was ground finely with an agate mortar, compressed into a disc with a diameter of 13mm by a tablet press, and then covered with alumina powder, placed on an alumina plate and calcined at 1200°C for 90 minutes in the air. Obtain flake SrBi7.8-xErxYb0.2Ti7O27Ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com