Novel photochromic material and preparation method thereof

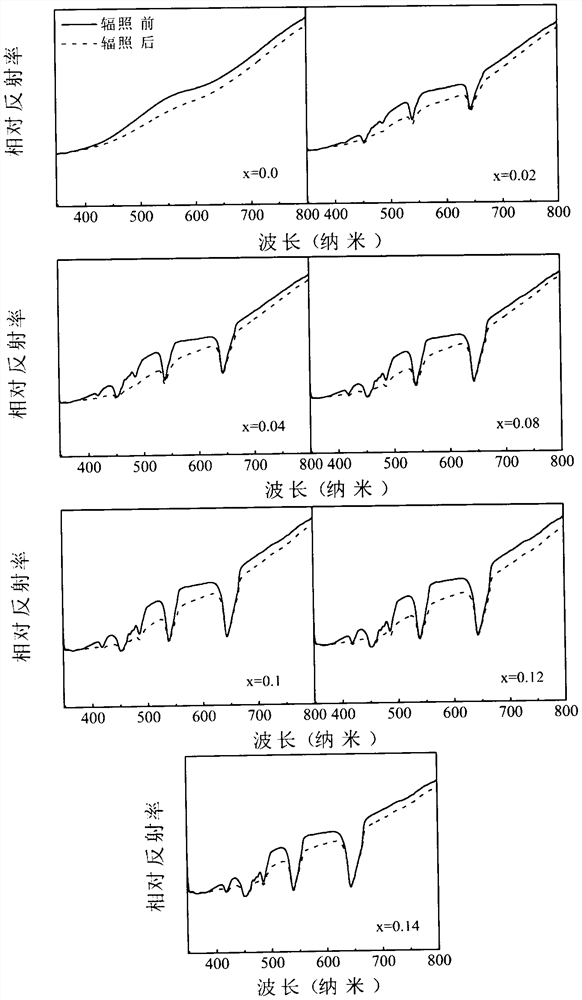

A photochromic material and a new technology, applied in the field of new photochromic materials and their preparation, can solve problems such as unsatisfactory performance, and achieve the effect of reducing the intensity of the diffuse reflectance spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

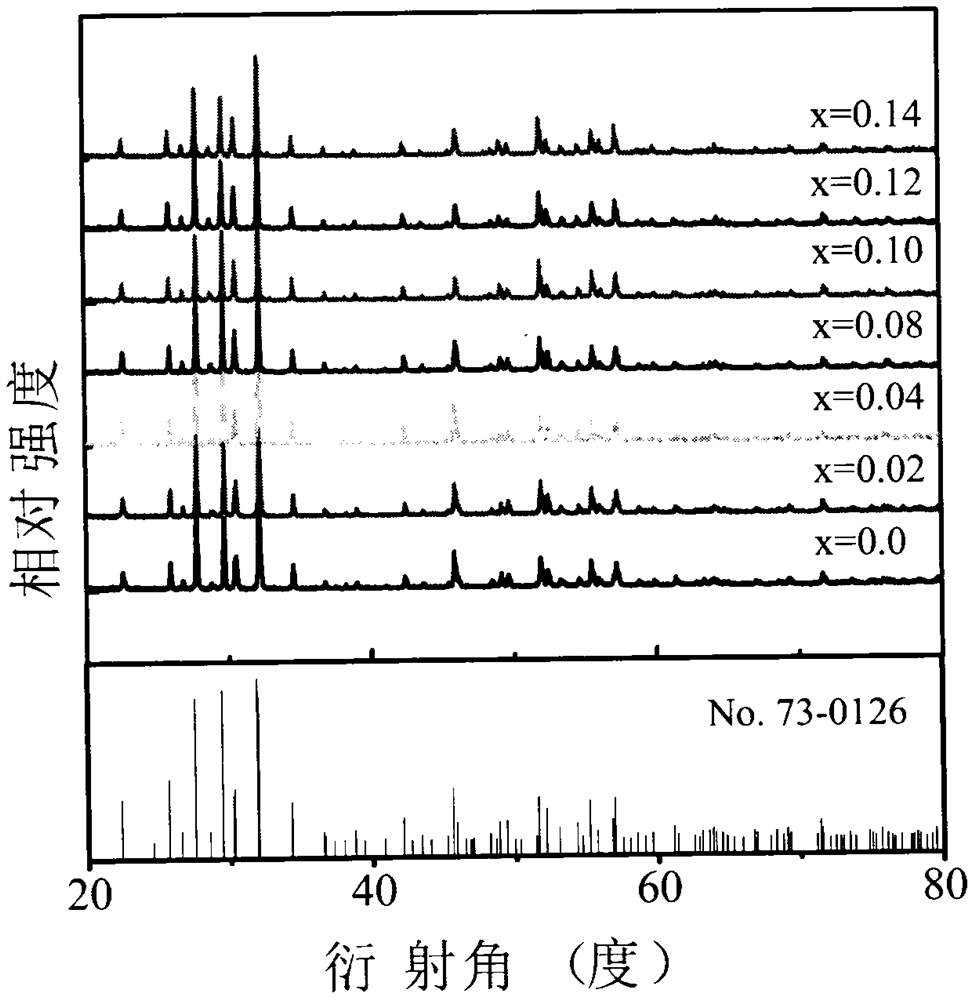

[0017] The up-conversion luminescence reversible control material provided in this embodiment is Ba 0.7 Sr 0.21-1.5x Ho x Yb 0.06 Nb 2 o 6 Ceramic material, wherein x=0.02, its preparation method is as follows:

[0018] Weigh 2.7907 g of BaCO 3 (99%), 0.5368 g SrCO 3 (99%), 0.0756 g Ho 2 o 3 (99.9%), 0.2367 g Yb 2 o 3 (99.9%) and 5.3167 g Nb 2 o 5 (99.99%), placed in a clean agate jar, using absolute ethanol (99.7%) as a solvent, grinding on a planetary ball mill to make a uniformly mixed powder for 24 hours. Then the above powder is dried in an oven, then placed in a corundum crucible, put into a box furnace, continuously raised to 1300°C for 3 hours, and then cooled to 550°C. Afterwards, the product obtained after cooling with the furnace is finely ground with an agate mortar, and the binder PVB (0.5% by weight of the product) is added, fully ground, mixed evenly, and granulated. A ceramic green sheet with a diameter of 13 mm was prepared under a pressure of 10...

Embodiment 2

[0020] The up-conversion luminescence reversible control material provided in this embodiment is Ba 0.7 Sr 0.21-1.5x Ho x Yb 0.06 Nb 2 o 6 Ceramic material, wherein x=0.08, its preparation method is as follows:

[0021] Weigh 2.7907 g of BaCO 3 (99%), 0.2684 g SrCO 3 (99%), 0.3026 g Ho 2 o 3 (99.9%), 0.2367 g Yb 2 o 3 (99.9%) and 5.3167 g Nb 2 o 5 (99.99%), placed in a clean agate jar, using absolute ethanol (99.7%) as a solvent, grinding on a planetary ball mill to make a uniformly mixed powder for 24 hours. Then the above powder is dried in an oven, then placed in a corundum crucible, put into a box furnace, continuously raised to 1300°C for 3 hours, and then cooled to 550°C. Afterwards, the product obtained after cooling with the furnace is finely ground with an agate mortar, and the binder PVB (0.5% by weight of the product) is added, fully ground, mixed evenly, and granulated. A ceramic green sheet with a diameter of 13 mm was prepared under a pressure of 10...

Embodiment 3

[0023] The up-conversion luminescence reversible control material provided in this embodiment is Ba 0.7 Sr 0.21-1.5x Ho x Yb 0.06 Nb 2 o 6 Ceramic material, wherein x=0.12, its preparation method is as follows:

[0024] Weigh 2.7907 g of BaCO 3 (99%), 0.0895 g SrCO 3 (99%), 0.4539 g Ho 2 o 3 (99.9%), 0.2367 g Yb 2 o 3 (99.9%) and 5.3167 g Nb 2 o 5(99.99%), placed in a clean agate jar, using absolute ethanol (99.7%) as a solvent, grinding on a planetary ball mill to make a uniformly mixed powder for 24 hours. Then the above powder is dried in an oven, then placed in a corundum crucible, put into a box furnace, continuously raised to 1300°C for 3 hours, and then cooled to 550°C. Afterwards, the product obtained after cooling with the furnace is finely ground with an agate mortar, and the binder PVB (0.5% by weight of the product) is added, fully ground, mixed evenly, and granulated. A ceramic green sheet with a diameter of 13 mm was prepared under a pressure of 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com