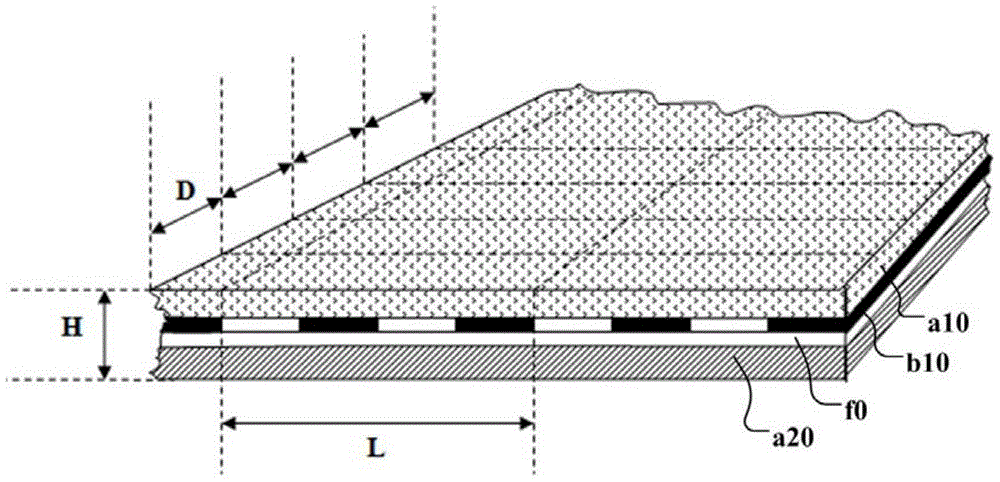

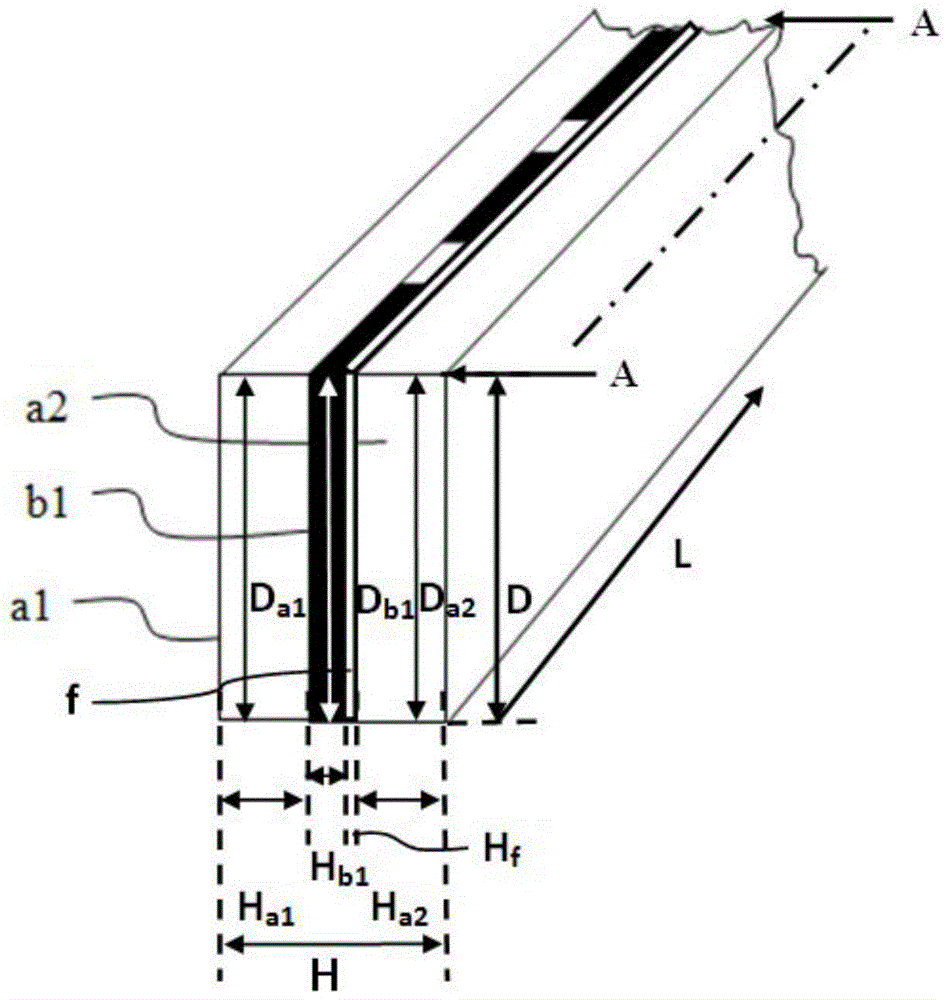

A kind of anti-counterfeiting fiber and its preparation method

An anti-counterfeiting fiber and fiber technology, applied in fiber raw material processing, non-fiber pulp addition, textile and papermaking, etc., can solve the problems of complex process, high equipment requirements, fiber design and production restrictions, etc., to achieve easy identification of interest, strong anti-counterfeiting. The effect of ability, good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Step 1, with 91.6% polyamide (DuPont, PA12), 8% fluorescent powder A (Beijing Jinglue Anti-counterfeiting Technology Development Co., Ltd., colorless fluorescent red powder), 0.4% dispersant (Shanghai Sanzheng Polymer Material Co., Ltd., CH-1A) After being uniformly mixed by a high-speed kneader, the first fluorescent film with a thickness of 30 μm was made by twin-screw extrusion granulation, melt extrusion casting without stretching, and corona.

[0101] Mix 94.7% polyamide (same as above), 5% fluorescent powder B (Beijing Jinglue Anti-counterfeiting Technology Development Co., Ltd., colorless fluorescent blue powder), and 0.3% dispersant (same as above) through a high-speed kneader, and pass Twin-screw extrusion granulation, melt extrusion casting, 3-4 times stretching in the longitudinal direction, and corona to make a second fluorescent film with a thickness of 30 μm.

[0102] 35% alcohol-soluble copolyamide (DuPont, Elvamide8061), 3.5% titanium dioxide (DuPont, R9...

Embodiment 2

[0116] Step 1, take a 15μm thick PET aluminum-coated film, in which the thickness of the aluminum layer is 20nm (DuPont Hongji, model MA), and hollow out the aluminum-coated layer with a laser to form grid-like stripes with a pitch of 2mm, a width of 2mm, and a thickness of 20nm aluminum layer.

[0117] Step 2, the phosphor powder A that mass fraction is 5% is dispersed in polyvinyl alcohol aqueous solution, and then this solution is coated on one side of the aluminum layer of grid-like stripes of PET aluminized film (solution will be embedded in the coating process In the gaps of grid stripes), the first fluorescent film was obtained after coating and drying, with a thickness of 10 μm. Then, in the same way, a polyvinyl alcohol aqueous solution dispersed with phosphor powder B with a mass fraction of 5% was coated on the other side of the PET aluminized film in the same way, and the second fluorescent film was obtained after coating and drying, with a thickness of 10 μm. The...

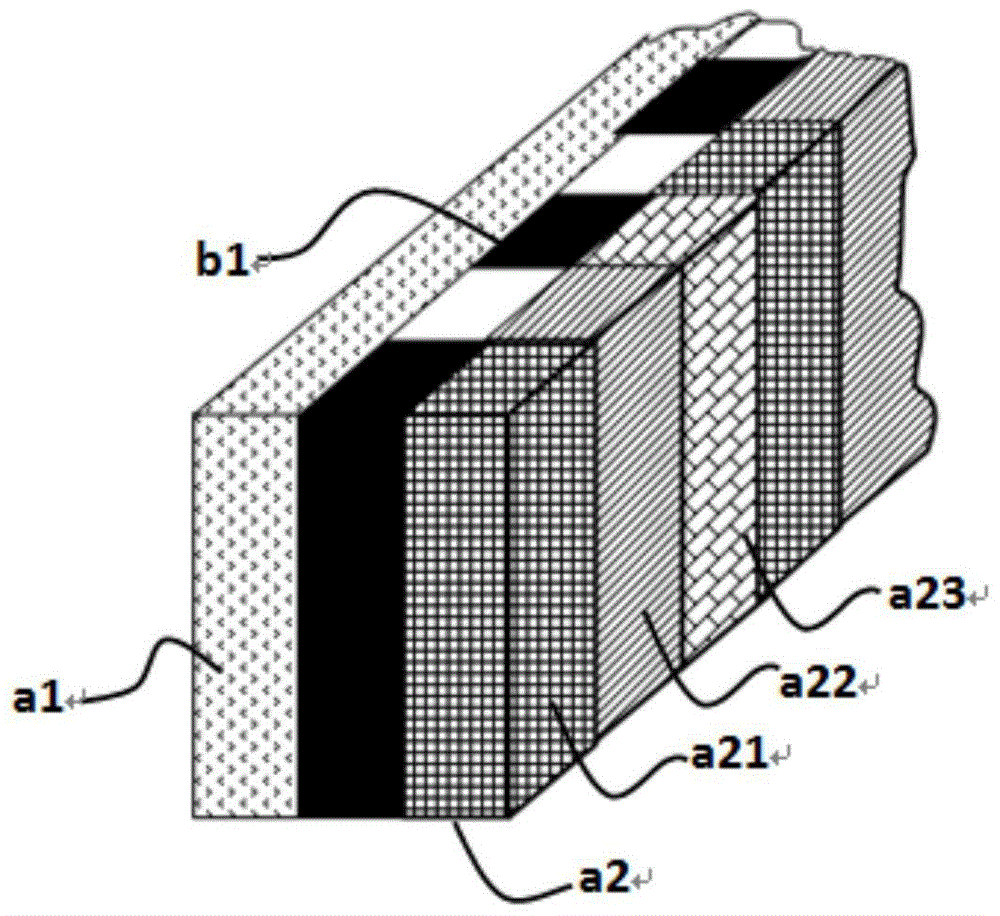

Embodiment 3

[0125] step 1,

[0126] (1) After mixing 89.3% polyamide (same as Example 1), 10% fluorescent powder B (same as Example 1), and 0.7% dispersant (same as Example 1) through a high-speed kneader, pass through double The second fluorescent masterbatch was obtained by screw extrusion, and then the masterbatch was fed into a biaxially stretched film device to make a second fluorescent film a2 with a thickness of 28 μm.

[0127] (2) The first fluorescent ink made of 35% alcohol-soluble copolyamide (same as above), 5% phosphor A (same as above), and 60% ethanol.

[0128] (3) 35% alcohol-soluble copolyamide (same as Example 1), 3.5% titanium dioxide (same as Example 1), 0.3% UV absorber (same as Example 1), 61.2% ethanol made of ultraviolet absorbing ink.

[0129] It is also possible to add pigments that are colored under natural light during the preparation of the UV-absorbing ink, so that the color of the barrier layer and the fluorescent layer under natural light are different. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com