A method of firing photochromic Jun porcelain under oxidative atmosphere conditions

An oxidizing atmosphere and photochromic technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem that the color and shape changes of Jun porcelain cannot satisfy Jun porcelain lovers, and avoid pollution and energy. the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

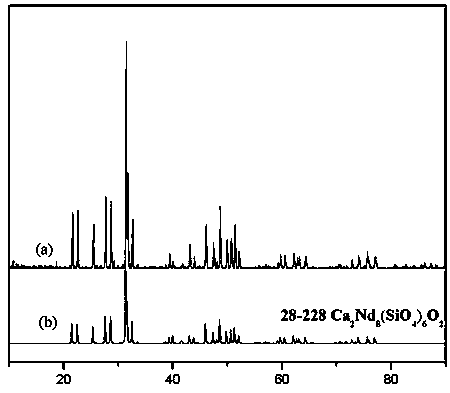

[0037] 1. Preparation of color-changing powder: The chemical formula is Ca2Nd8(SiO4)6O2 calcium neodymium silicon neodymium powder prepared by in-situ solid-state reaction method. Weigh calcium carbonate, neodymium oxide and silicon dioxide according to the stoichiometric ratio, put the weighed raw materials into an agate mortar, add a small amount of absolute ethanol, and grind clockwise and counterclockwise for 30 minutes to make them fully mixed Put it into a blast drying oven, set the temperature at 120°C, and dry for 3 hours; take out the dried powder, grind it again by the above method, and dry it for later use. Put the mixed raw materials into a corundum crucible and put them into a muffle furnace. The heating rate is 5°C / min, the sintering temperature is 1350°C, and the temperature is kept for 30 minutes. Then, the required color-changing silicon neodymium salt powder is prepared. The discoloration effect diagram of the discoloration calcium neodymium silicon neodymate...

Embodiment 2

[0041] 1. Preparation of color-changing powder: with embodiment 1.

[0042]2. Preparation steps of color-changing Jun porcelain: Add calcium neodymium silicon neodymium powder into the base glaze of Jun porcelain according to the mass ratio of 15% of the glaze, use a constant temperature heating magnetic stirrer, set the speed at 500r / min, and stir for 60 minutes. It is evenly distributed in the glaze; the uniformly mixed glaze is coated on the biscuit by dipping glaze; after the glaze is completed, it is dried naturally overnight to fully evaporate the water in the glaze layer; put it into the muffle furnace, set Set the heating rate at 3°C / min, glaze the firing temperature at 1280°C, keep it warm for 20 minutes, and then cool down with the furnace to obtain the color-changing Jun porcelain product. The discoloration effect of the color-changing Jun porcelain test piece prepared under this condition is shown in diagram 2-1 .

[0043] 3. Summary of this example: from diag...

Embodiment 3

[0045] 1. Preparation of color-changing powder: with embodiment 1.

[0046] 2. Preparation steps of color-changing Jun porcelain: add silicon neodymium salt powder into Jun porcelain base glaze according to the mass ratio of 25% of the glaze, use a constant temperature heating magnetic stirrer, set the speed at 500r / min, and stir for 60 minutes. It is evenly distributed in the glaze; the uniformly mixed glaze is coated on the biscuit by dipping glaze; after the glaze is completed, it is dried naturally overnight to fully evaporate the water in the glaze layer; put it into the muffle furnace, set Set the heating rate at 3°C / min, glaze the firing temperature at 1280°C, keep it warm for 20 minutes, and then cool down with the furnace to obtain the color-changing Jun porcelain product. The discoloration effect of the color-changing Jun porcelain prepared under this condition is shown in Figure 3-1 .

[0047] 3. Summary of this example: from Figure 3-1 It can be seen that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com