A printing paste based on nano-gold and its application on silk fabrics

A printing paste, nano-gold technology, applied in animal fiber, textile and papermaking, biochemical fiber processing and other directions, can solve many problems, achieve the effect of colorful and changeable, colorful and luster, and reduce the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

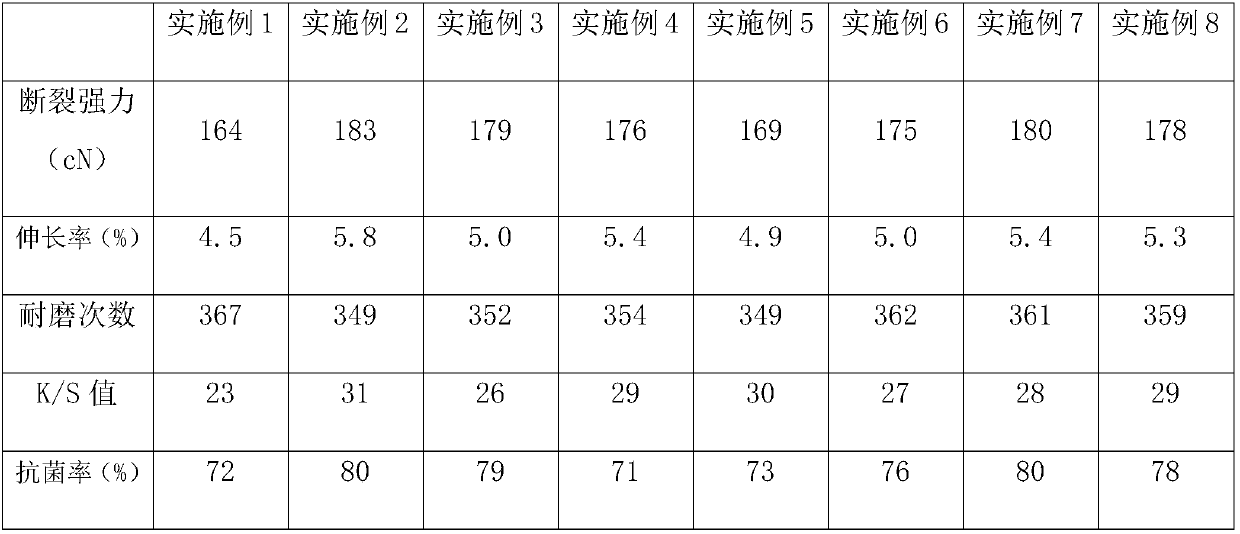

Examples

Embodiment 1

[0027] (1) Add gold powder with a particle size of 0.2 mm into a sodium hydroxide solution with a mass fraction of 1%, and after ultrasonic treatment for 20 min, take it out and fully wash it with deionized water to obtain a modified gold powder.

[0028] (2) In parts by weight, the modified gold powder of 5 parts, the sol containing 2 parts of particle diameters of 5-30nm dumbbell-shaped nano gold, the mixed solution containing 3 parts of carbon nanotubes and 20 parts of water, 5 parts of The imidazoline surfactant and 8 parts of citric acid were added to 100 parts of polyacrylic acid slurry, fully stirred, and ground to form a printing slurry based on gold nanoparticles.

[0029] (3) Wash and dry the surface of the silk fabric, directly coat the printing paste based on nano-gold on the surface of the silk fabric, remove excess paste to form a paste layer with a thickness of 0.5mm, and lay some fabrics with a thickness of 0.12mm μm gold foil, and hot-rolled at 70°C and 3bar p...

Embodiment 2

[0031] (1) Add gold powder with a particle size of 0.5 mm into a sodium hydroxide solution with a mass fraction of 2%, and after ultrasonic treatment for 30 min, take it out and fully wash it with deionized water to obtain a modified gold powder.

[0032] (2) In parts by weight, the modified gold powder of 10 parts, the sol containing 4 parts of particle diameters containing dumbbell-shaped nano-gold, the mixed solution containing 6 parts of carbon nanotubes and 40 parts of water, 12 parts of The imidazoline surfactant and 13 parts of citric acid were added to 100 parts of polyacrylic acid slurry, fully stirred, and ground to form a gold nano-based printing slurry.

[0033] (3) Wash and dry the surface of the silk fabric, directly coat the printing paste based on nano-gold on the surface of the silk fabric, remove excess paste to form a paste layer with a thickness of 1 mm, and lay part of the fabric with a thickness of 0.15 μm The gold foil was hot-rolled at 80 °C and 4 bar p...

Embodiment 3

[0035] (1) Add gold powder with a particle size of 0.3 mm into a sodium hydroxide solution with a mass fraction of 1.5%, and after ultrasonic treatment for 25 minutes, take it out and fully wash it with deionized water to obtain a modified gold powder.

[0036] (2) In parts by weight, the modified gold powder of 8 parts, the sol containing 3 parts of particle diameters of 5-30nm dumbbell-shaped nano gold, the mixed solution containing 4 parts of carbon nanotubes and 30 parts of water, 7 parts of The imidazoline surfactant and 10 parts of citric acid were added to 100 parts of polyacrylic acid slurry, fully stirred, and ground to form a gold nano-based printing slurry.

[0037] (3) Wash and dry the surface of the silk fabric, directly coat the printing paste based on nano-gold on the surface of the silk fabric, remove excess paste to form a paste layer with a thickness of 0.8mm, and lay some fabrics with a thickness of 0.13mm μm gold foil, and hot-rolled at 75°C and 3.5bar pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com