Photochromic fabric and preparation method thereof

A photochromic and fabric technology, applied in the field of photochromic fabrics and their preparation, can solve the problems of photochromic agent falling off, poor discoloration effect, and inability to satisfy consumers in functionality and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

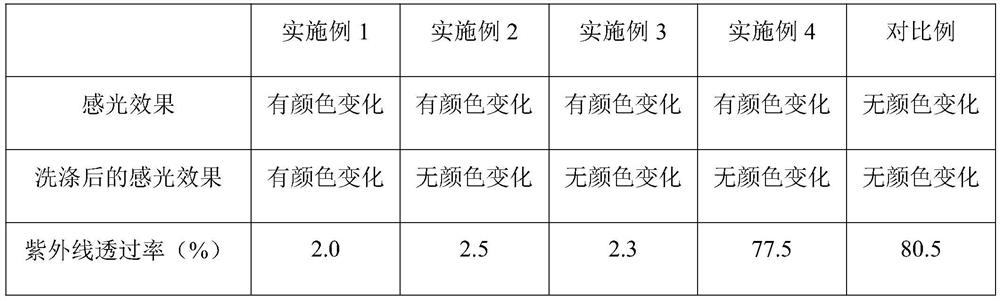

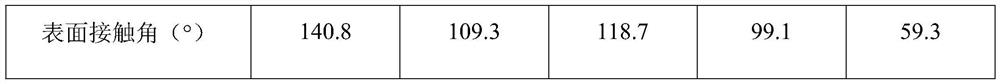

Examples

Embodiment 1

[0034] A photosensitive color-changing fabric mainly includes, by weight, 115 parts of cellulose, 172 parts of self-made spiropyran, and 138 parts of self-made benzotriazole.

[0035] A method for preparing a photosensitive color-changing fabric, the preparation method of the photosensitive color-changing fabric mainly includes the following preparation steps:

[0036] (1) Dissolving salicylaldehyde in 10.87 times of salicylaldehyde mass fraction is 2% sodium hydroxide solution, and is placed in an ice bath at -2°C to obtain salicylaldehyde-sodium hydroxide solution; the salicylaldehyde mass fraction is 0.64 Diaminobenzenesulfonanilide was dissolved in 50% sulfuric acid with 20 times the mass of salicylaldehyde, heated in a water bath at 120°C, stirred at 200rpm until dissolved, cooled until crystals no longer appeared, at 0°C, with 1mL Adding 0.2 times the mass fraction of salicylaldehyde mass at a speed of 35% nitrous acid solution to obtain a bright yellow clear solution; w...

Embodiment 2

[0049] A photosensitive color-changing fabric mainly includes, by weight, 115 parts of cellulose, 172 parts of self-made spiropyran, and 138 parts of self-made benzotriazole.

[0050] A method for preparing a photosensitive color-changing fabric, the preparation method of the photosensitive color-changing fabric mainly includes the following preparation steps:

[0051] (1) Place trimethylindole, iodopropionic acid with 1.24 times the mass of trimethylindole, and methyl ethyl ketone with 0.9 times the mass of trimethylindole in a two-necked bottle, and heat up to 100°C under a nitrogen atmosphere. After reflux reaction for 3 hours, keep it warm at 80°C for 28 minutes, add ultrapure water with 0.8 times the mass of trimethylindole, wash with chloroform until the solution is colorless, and rotary evaporate at 60°C and 200rpm for 17min to obtain trimethylindole iodide compound;

[0052] (2) Butanone with 11.9 times the mass of salicylaldehyde, trimethylindole iodide with 2.1 time...

Embodiment 3

[0063]A photosensitive color-changing fabric mainly includes, by weight, 115 parts of cellulose, 172 parts of modified salicylaldehyde, and 138 parts of self-made benzotriazole.

[0064] A method for preparing a photosensitive color-changing fabric, the preparation method of the photosensitive color-changing fabric mainly includes the following preparation steps:

[0065] (1) Dissolving salicylaldehyde in 10.87 times of salicylaldehyde mass fraction is 2% sodium hydroxide solution, and is placed in an ice bath at -2°C to obtain salicylaldehyde-sodium hydroxide solution; the salicylaldehyde mass fraction is 0.64 Diaminobenzenesulfonanilide is dissolved in 50% sulfuric acid with 20 times the mass of salicylaldehyde, heated in a water bath at 120°C, stirred at 200rpm until dissolved, cooled until crystals no longer appear, at 0°C, with 1mL / Adding 0.2 times the mass fraction of salicylaldehyde mass fraction at a speed of min is a 35% nitrous acid solution to obtain a bright yello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com