A kind of hydrogel nanocomposite material and its preparation method and application

A nanocomposite material and hydrogel nanotechnology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of easy agglomeration of materials, secondary pollution, etc., and achieve pollution avoidance and no secondary pollution , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Take 1g of lignin, 0.5g of acrylamide, 0.1g of maleic anhydride, 0.01g of cross-linking agent N,N'-methylenebisacrylamide and 0.5g of ferric chloride, add 20mL of deionized water, Dissolve completely with magnetic stirring.

[0044] (2) Add 2 mL of ammonia water (concentration: 25%) to the solution obtained in step (1) to adjust the pH to alkaline. 0.01 g of potassium persulfate was added as an initiator. Subsequently, 10 μL of tetramethylethylenediamine was added, stirred thoroughly and left to stand for 1 h to obtain a composite hydrogel.

[0045] (3) Soak the composite hydrogel obtained in (2) in 0.1mol / L sodium sulfide solution for 6 hours to obtain a black hydrogel, wash it with deionized water several times, and put it in the refrigerator for 12 hours at -10°C , freeze-dried for 12 hours, the heavy metal-removed hydrogel nanocomposite can be obtained.

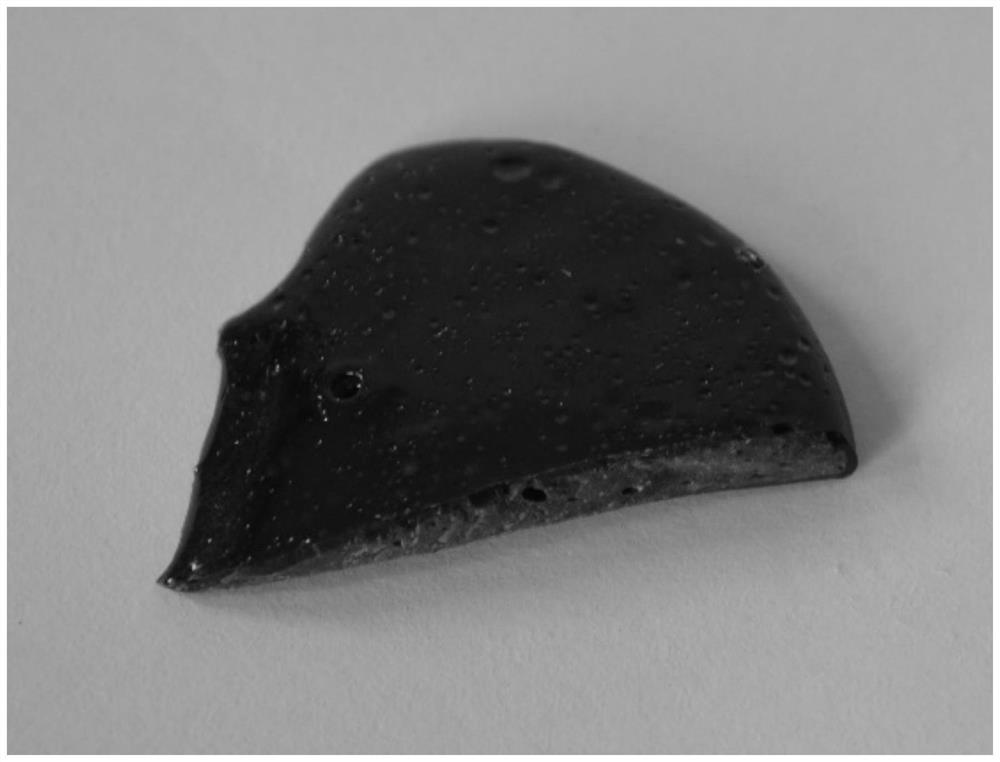

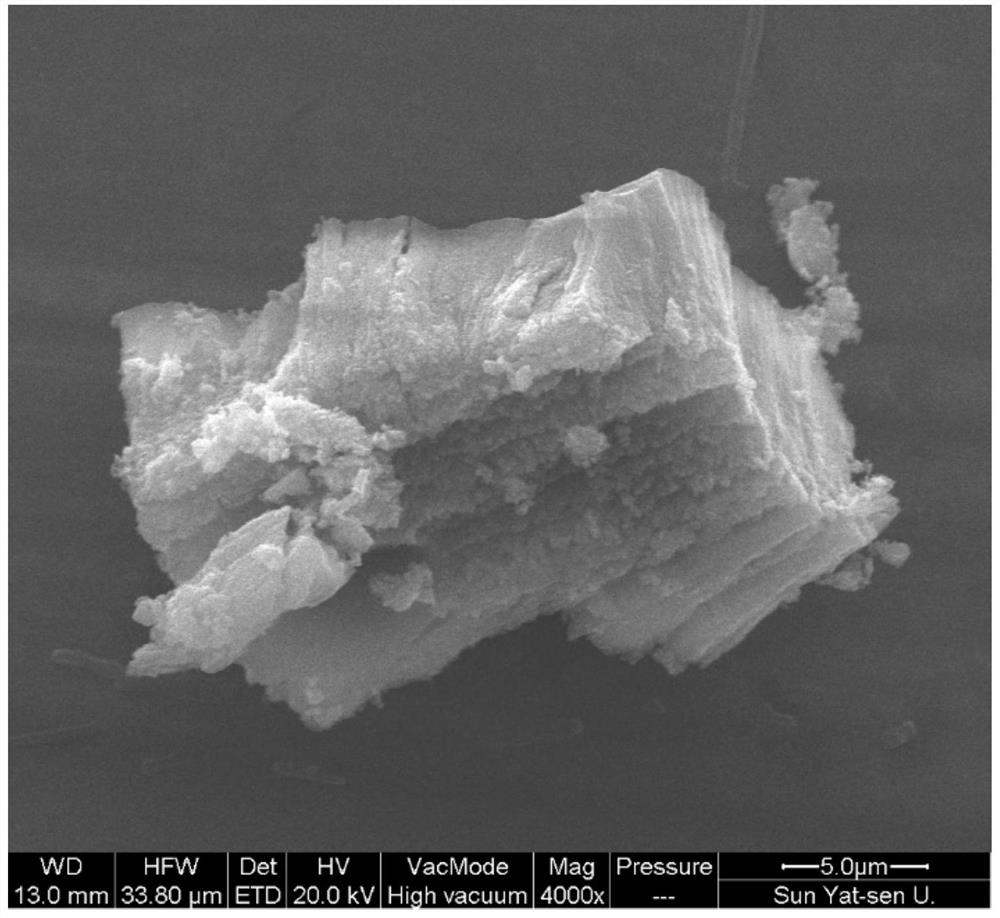

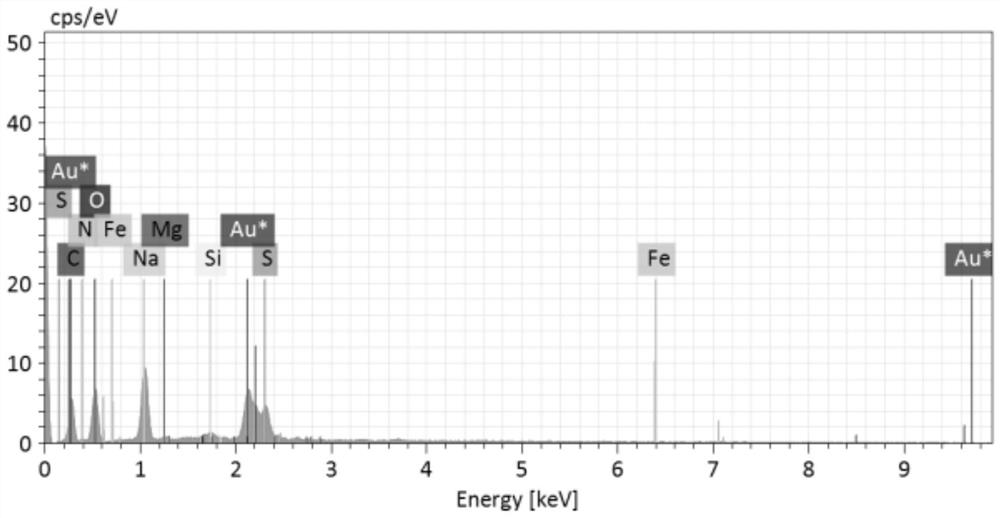

[0046] figure 1 The physical picture of the hydrogel nanocomposite material prepared in this embodiment ...

Embodiment 2

[0048] (1) Take 10g of lignin, 1.5g of acrylamide, 0.5g of maleic anhydride, 0.015g of cross-linking agent N,N'-methylenebisacrylamide and 5g of ferrous chloride, add 100mL of deionized water, Dissolve completely with magnetic stirring.

[0049] (2) Add 10 mL of 10% potassium hydroxide to the solution obtained in step (1) to adjust the pH to alkaline. 0.03 g of potassium persulfate was added as an initiator. Subsequently, 40 μL of tetramethylethylenediamine was added, stirred thoroughly and left to stand for 5 h to obtain a composite hydrogel.

[0050] (3) Soak the composite hydrogel obtained in step (2) in 0.5 mol / L sodium sulfide solution for 24 hours to obtain a black hydrogel, wash it several times with deionized water, and put it in the refrigerator for 2 hours at -20°C Afterwards, freeze-dry for 24 hours to obtain a hydrogel nanocomposite material with heavy metals removed.

Embodiment 3

[0052] (1) Take 5g of lignin, 1g of acrylamide, 0.3g of maleic anhydride, 0.012g of cross-linking agent N,N'-methylenebisacrylamide and 2g of ferrous sulfate, add 50mL of deionized water, and stir magnetically Dissolve completely.

[0053] (2) Add 5 mL of 10% sodium hydroxide to the solution obtained in step (1) to adjust the pH to alkaline. 0.02 g of potassium persulfate was added as an initiator. Subsequently, 20 μL of tetramethylethylenediamine was added, stirred thoroughly and left to stand for 3 h to obtain a composite hydrogel.

[0054] (3) Soak the composite hydrogel obtained in step (2) in 0.3mol / L sodium sulfide solution for 12 hours to obtain a black hydrogel, wash it several times with deionized water, and put it in the refrigerator for 6 hours at -15°C Afterwards, freeze-dry for 18 hours to obtain a hydrogel nanocomposite material with heavy metals removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com