A kind of carborane-based superhydrophobic material and its preparation method and application

A technology of alkoxysilylpropylcarborane and carborane, which is applied in the field of preparation of superhydrophobic functional materials, can solve the problems of cumbersome preparation steps, limited stability and hydrophobicity of oil-water separation materials, and achieve simple operation of the preparation method , excellent stability and acid and alkali resistance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

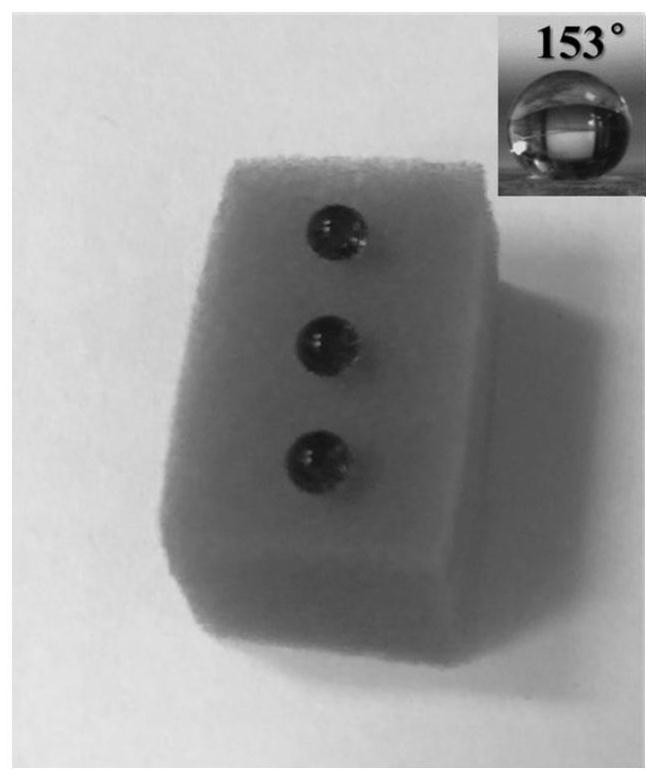

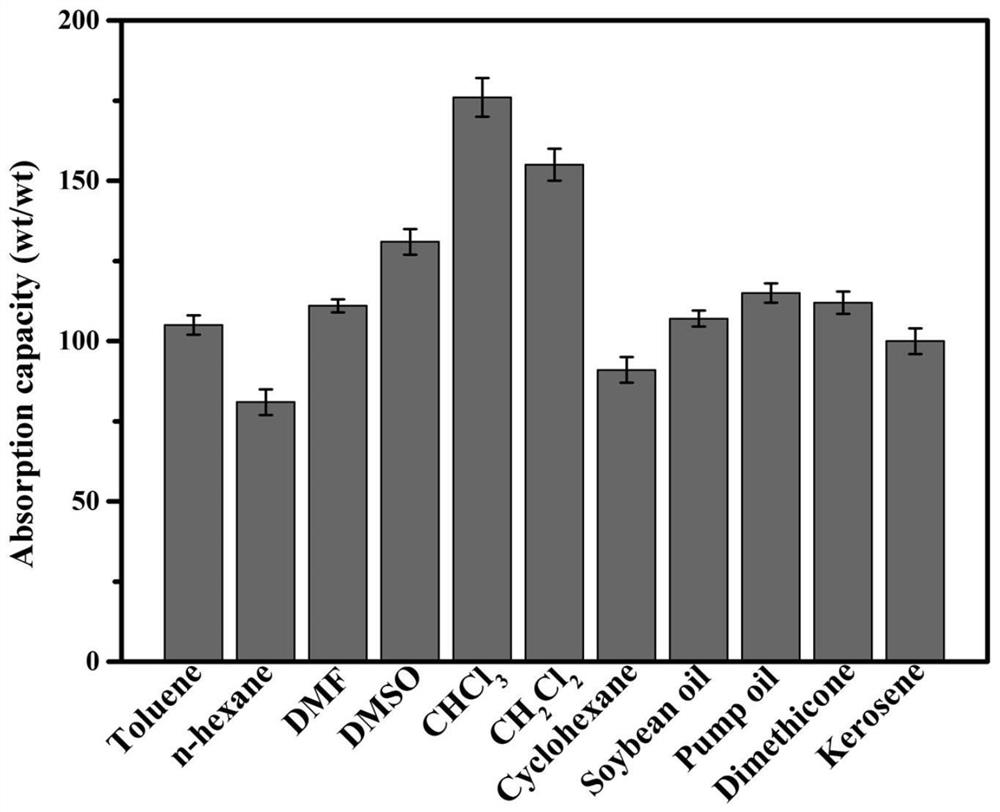

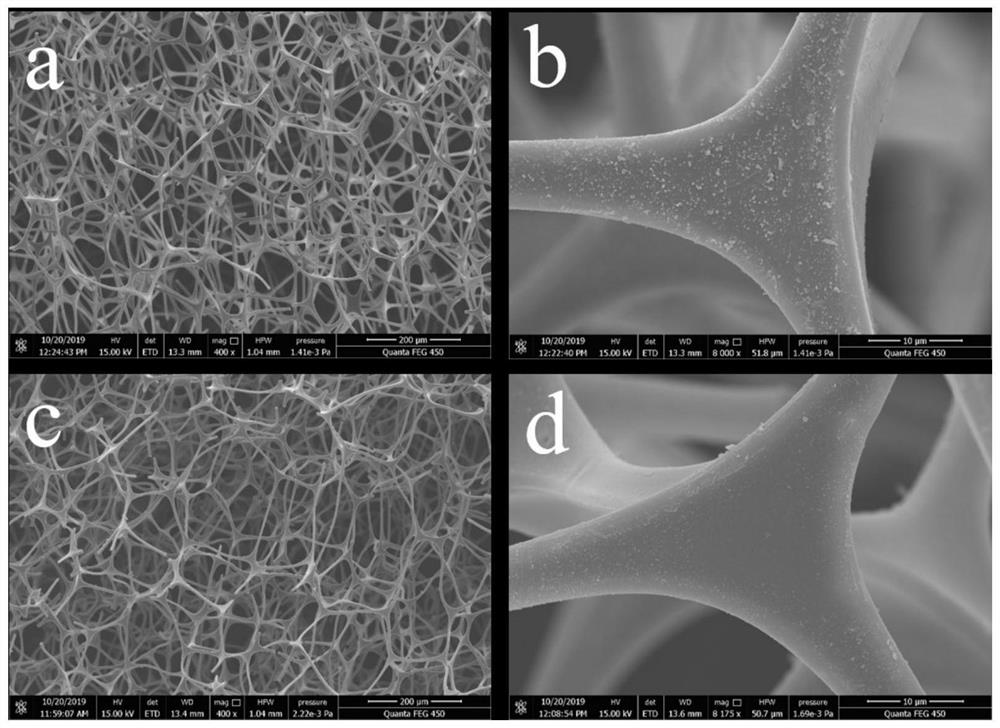

Embodiment 1

[0029] The melamine sponge was fully washed with water and ethanol and immersed in 4mg / ml dopamine Tris buffer, after stirring for 12 hours, it was taken out and washed with water and ethanol until the washing solution was clear, and vacuum-dried for 12 hours to obtain a polydopamine-coated sponge material. Put the obtained sponge into the ethanol solution of 20 mg / ml monosubstituted trimethoxysilylpropyl carborane, heat it at 60°C for 24 hours, take it out, wash it with ethanol three times, and dry it in vacuum to obtain the carborane covalent Connected superhydrophobic sponge material. The preparation method of the monosubstituted trimethoxysilylpropyl carborane is as follows: under the protection of nitrogen, dissolve 300 mg of o-carborane in 9 ml of anhydrous ether, and cool to 0 ° C and dropwise add 1.6 ml of n-butyllithium , stirred at room temperature for 3 hours, cooled to 0°C again, added 370 μl bromopropyltrimethoxysilane, stirred the mixture at room temperature for ...

Embodiment 2

[0034] The melamine sponge was fully washed with water and ethanol and immersed in 2mg / ml dopamine Tris buffer, after stirring for 12 hours, it was taken out and washed with water and ethanol until the washing solution was clear, and vacuum-dried for 12 hours to obtain a polydopamine-coated sponge material. Put the obtained sponge into a 10 mg / ml ethanol solution of monosubstituted trimethoxysilylpropyl carborane, heat it at 60°C for 24 hours, wash it with ethanol three times after taking it out, and obtain the carborane covalent Connected superhydrophobic sponge material. The preparation method of the monosubstituted trimethoxysilylpropyl carborane is as follows: under the protection of nitrogen, dissolve 300 mg of o-carborane in 9 ml of anhydrous ether, and cool to 0 ° C and dropwise add 1.6 ml of n-butyllithium , stirred at room temperature for 3 hours, cooled to 0°C again, added 370 μl bromopropyltrimethoxysilane, stirred the mixture at room temperature for 25 hours and qu...

Embodiment 3

[0037] The polyurethane sponge was fully washed with water and ethanol and immersed in 4mg / ml dopamine Tris buffer. After stirring for 12 hours, it was taken out and washed with water and ethanol until the washing solution was clear. After vacuum drying for 12 hours, polydopamine-coated sponge material was obtained. Put the obtained sponge into a 10 mg / ml ethanol solution of monosubstituted trimethoxysilylpropyl carborane, heat it at 40°C for 20 hours, wash it with ethanol three times after taking it out, and obtain the carborane covalent Connected superhydrophobic sponge material. The preparation method of the monosubstituted trimethoxysilylpropyl carborane is as follows: under the protection of nitrogen, dissolve 300 mg m-carborane in 9 ml of anhydrous ether, and cool to 0 ° C and dropwise add 1.6 ml of n-butyllithium , stirred at room temperature for 3 hours, cooled to 0°C again, added 370 μl bromopropyltrimethoxysilane, stirred the mixture at room temperature for 25 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com