A method and device for efficiently purifying biogas using the principle of pressure swing adsorption

A pressure swing adsorption, biogas technology, applied in gas fuel, waste fuel, petroleum industry and other directions, can solve the problems of high energy consumption, low efficiency of biogas purification, large volume and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

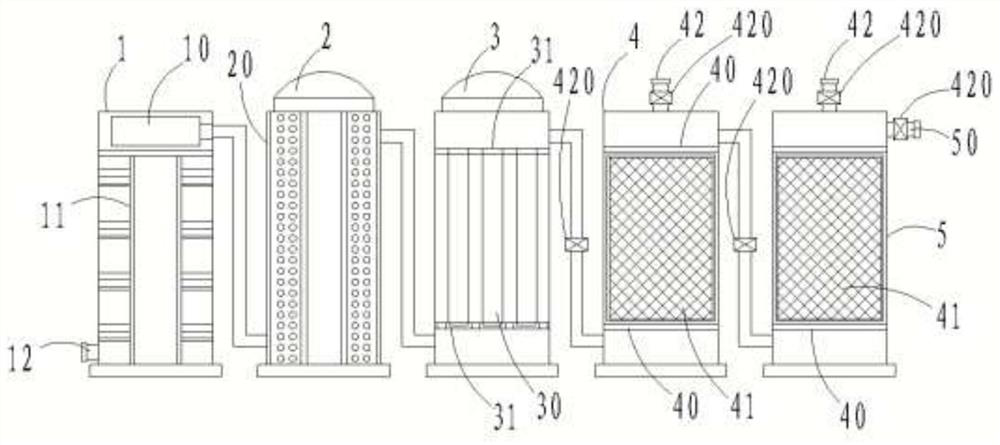

[0031] Embodiment 1: A method for efficiently purifying biogas using the principle of pressure swing adsorption, comprising the following steps:

[0032] S1, pretreatment;

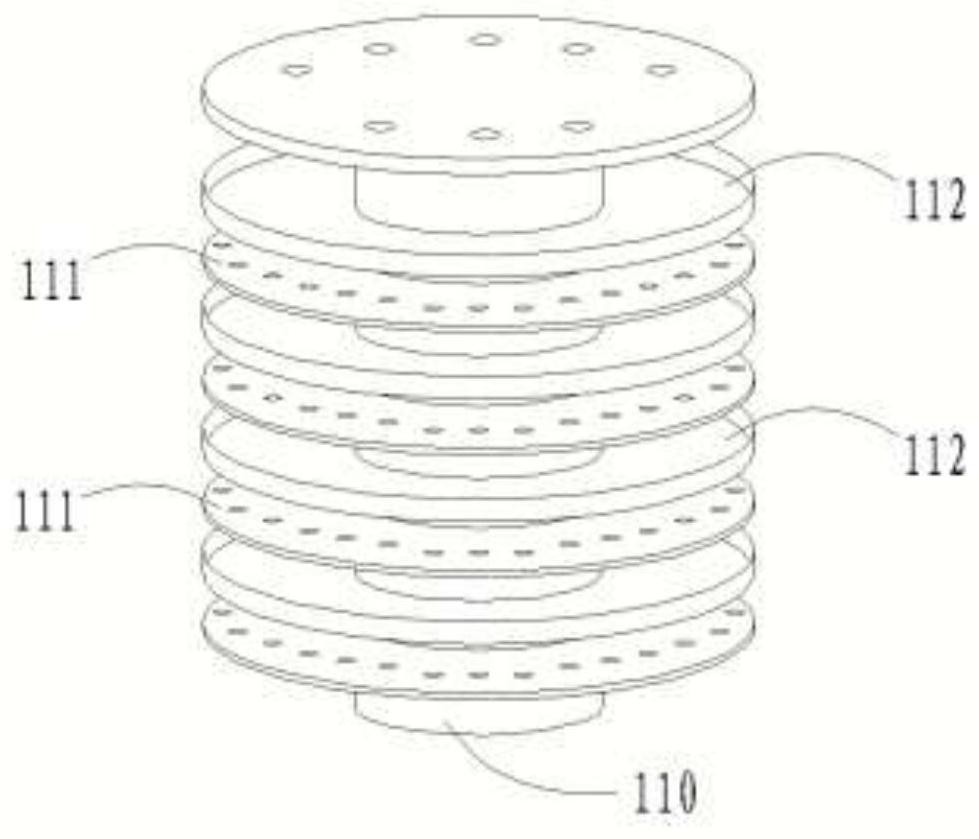

[0033] S11. Pass the biogas produced after anaerobic fermentation into the desulfurization tower 1, and use the desulfurizer in the desulfurization tower 1 to remove the sulfide in the biogas. The desulfurizer is a commercially available biogas desulfurizer;

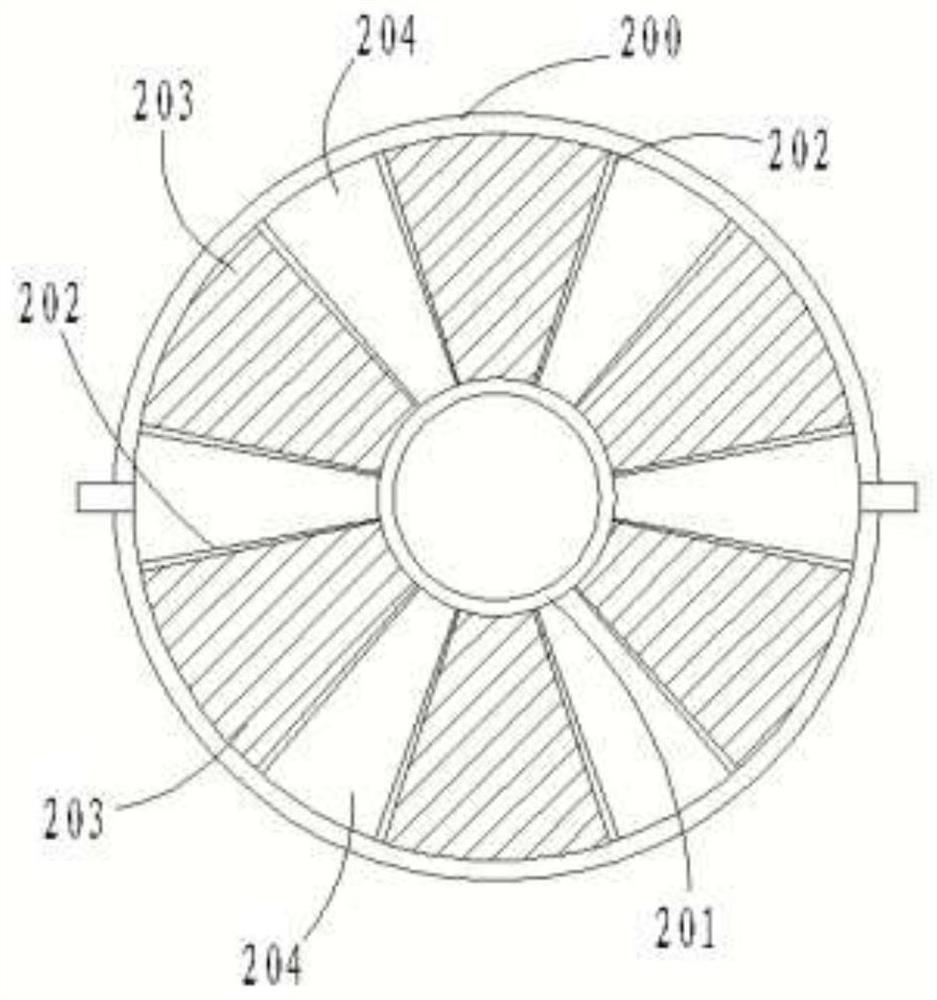

[0034] S12. Pass the biogas desulfurized in step S11 into the drying tower 2 to remove the moisture in the desulfurized biogas so that the water content of the desulfurized biogas is 2 mg / kg to obtain dry biogas; the desiccant used in the drying tower 2 is commercially available Silica gel desiccant sold;

[0035] S13, pass the dried biogas obtained in step S12 into the filter tower 3 to remove insoluble impurities in the dried biogas; adjust the pressure of the outlet gas from the filter tower 3 to 0.5MPa to obtain compressed biogas; the filter mem...

Embodiment 2

[0041] Embodiment 2: A method for efficiently purifying biogas by using the principle of pressure swing adsorption, comprising the following steps:

[0042] S1, pretreatment;

[0043] S11. Pass the biogas produced after anaerobic fermentation into the desulfurization tower 1, and use the desulfurizer in the desulfurization tower 1 to remove the sulfide in the biogas. The desulfurizer is a commercially available biogas desulfurizer;

[0044] S12. Pass the biogas desulfurized in step S11 into the drying tower 2 to remove the moisture in the desulfurized biogas so that the water content of the desulfurized biogas is 6 mg / kg to obtain dry biogas; the desiccant used in the drying tower 2 is commercially available Silica gel desiccant sold;

[0045] S13, pass the dried biogas obtained in step S12 into the filter tower 3 to remove insoluble impurities in the dried biogas; adjust the pressure of the outlet gas from the filter tower 3 to 0.8MPa to obtain compressed biogas; the filter ...

Embodiment 3

[0051] Embodiment 3: A method for efficiently purifying biogas by using the principle of pressure swing adsorption, comprising the following steps:

[0052] S1, pretreatment;

[0053] S11, pass the biogas produced after anaerobic fermentation into the desulfurization tower 1, and use the desulfurizer in the desulfurization tower 1 to remove the sulfide in the biogas. In step S11, the desulfurizer is composed of the following raw materials by weight: organic amine desulfurizer 15 parts, 8 parts of sulfoxide, 1 part of polyethylene glycol, 5 parts of propylene carbonate, and 20 parts of deionized water. The desulfurizer under this ratio has a longer service life, thereby reducing the frequency of replacement of the desulfurizer. Improve economic benefits; the preparation method of the desulfurizer is: mix and react the organic amine desulfurizer with sulfoxide and polyethylene glycol, control the reaction pH value to 6, and generate colloidal precipitate; use the colloidal preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com