Rim installation assembly of suspended ceiling

A technology for installing components and curling, which is applied to ceilings, building components, buildings, etc., can solve problems such as the influence of the shape of the keel structure on the structural stability, and achieve the effects of ensuring structural stability, reducing use, and improving the ability of earthquake resistance and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

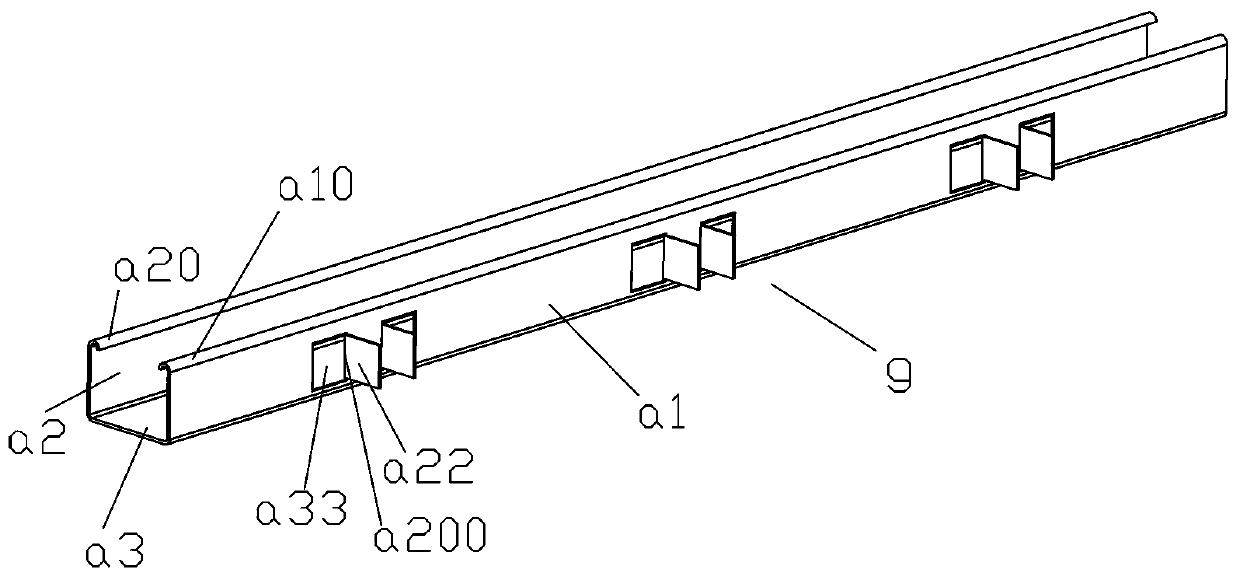

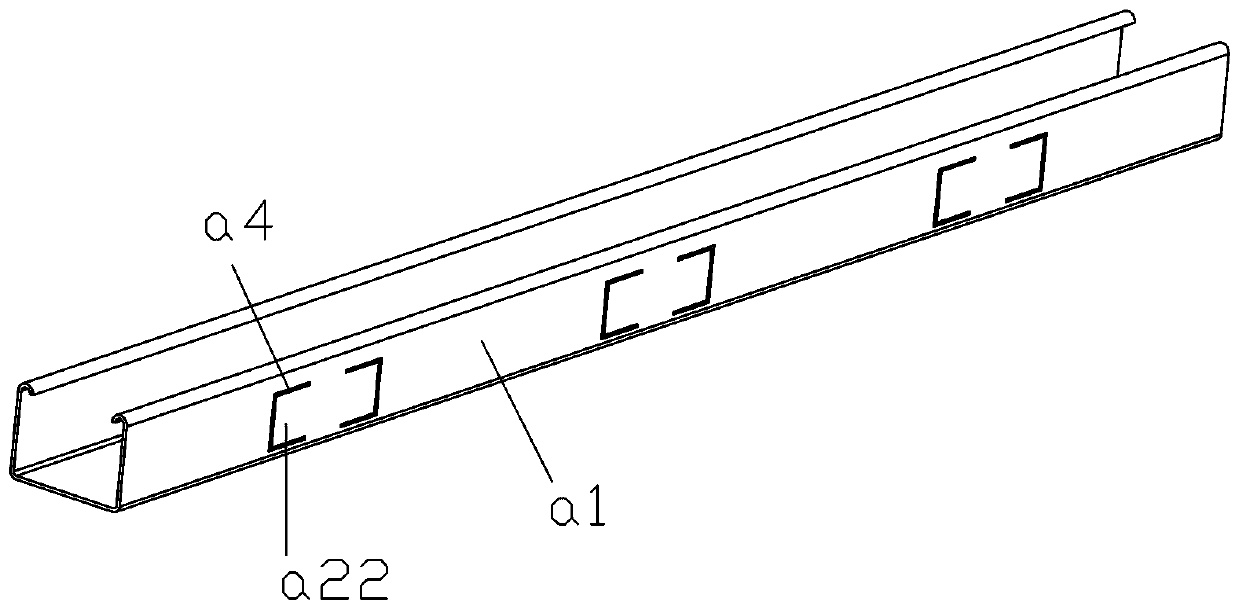

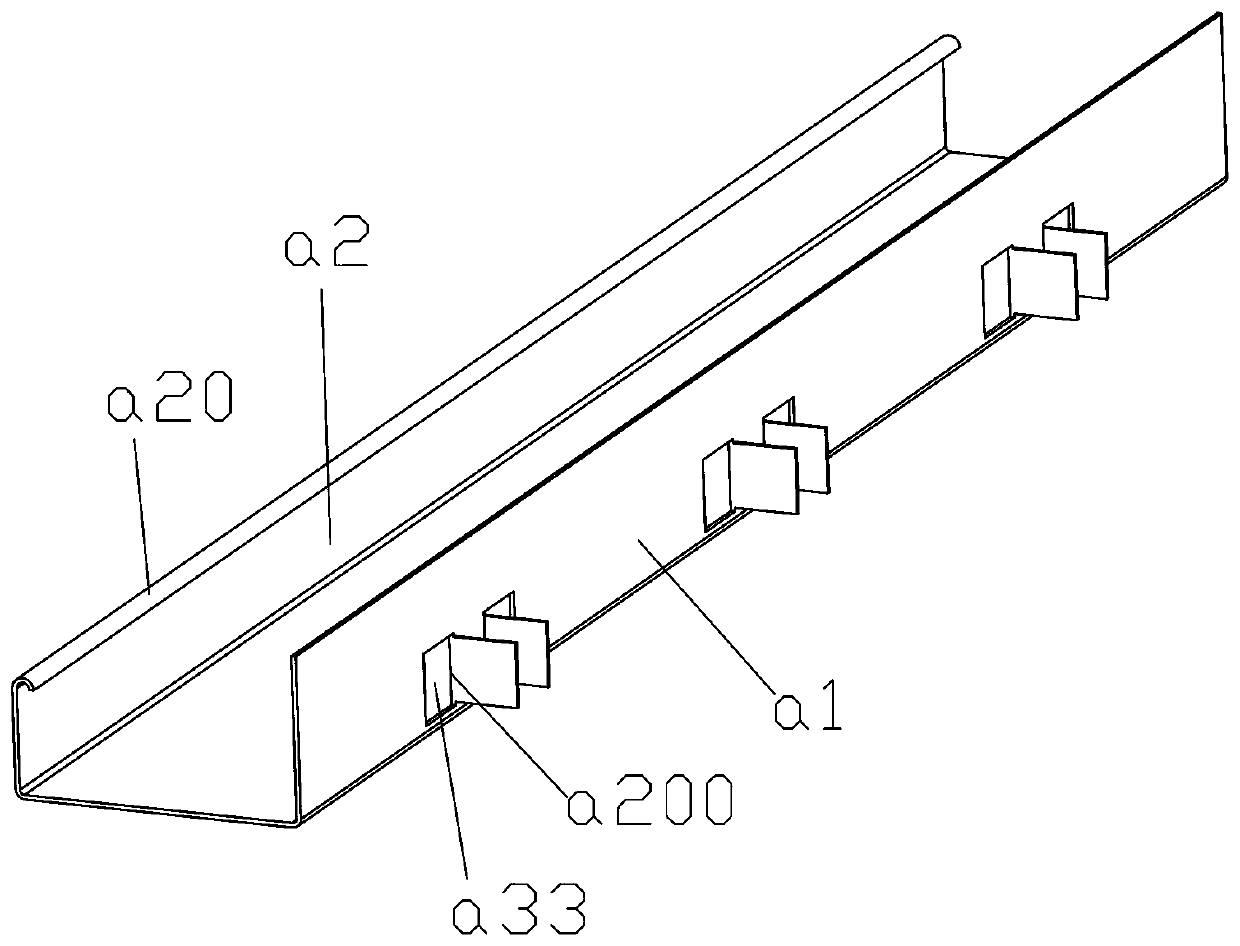

[0028] Example 1, such as Figure 1-4 As shown, a keel for ceiling installation includes an upright main side installation support plate a1, the main side installation support plate a1 is preferably a strip-shaped plate structure extending in the direction of the horizontal plane, and more preferably The whole is a rectangular strip-shaped structure, and the main side installation support plate a1 is integrally connected with a side plate protruding from the main side installation support plate a1 and intersecting with the main side installation support plate a1 Outward convex connecting plate a22. The convex connection plate a22 is integrally connected to the installation support plate a1 on the main side, but because of its convexity, it can be used as an installation bridge with other keels, and because it is installed on the main side The horizontal side area of the support plate a1 makes it It can be used as the main keel to complete the connection with the keel beside...

Embodiment 2

[0035] Example 2, such as Figure 5-9 As shown, a side keel assembly includes a keel for ceiling installation in the foregoing embodiment as the main keel, and also includes an intermediate transition auxiliary keel b installed on the outwardly convex connecting plate a22, and the intermediate transition The end of the auxiliary keel b away from the outwardly convex connecting plate a22 is installed into the outer keel c.

[0036] The specific scheme, the so-called side keel assembly, can also be called the side installation assembly of the suspended ceiling, which is suitable for the enclosed frame-type suspended ceiling structure, including the main keel g, and the outer part of the main keel g is connected with more than two pieces The protruding connecting plates a22 arranged at intervals along the length extension direction of the main keel g, wherein at least one group of adjacent two protruding connecting plates a22 are plugged into one end of an intermediate transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com