Novel nuclear-powered ship high-pressure steam automatic decompression device and method

A high-pressure steam, automatic decompression technology, applied in safety devices, engine components, machines/engines, etc., can solve the problems of auxiliary steam system configuration, complicated system adjustment and operation, reduced system reliability, and no equipment backup. The effect of simplifying the adjustment operation mode, strong adjustment ability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

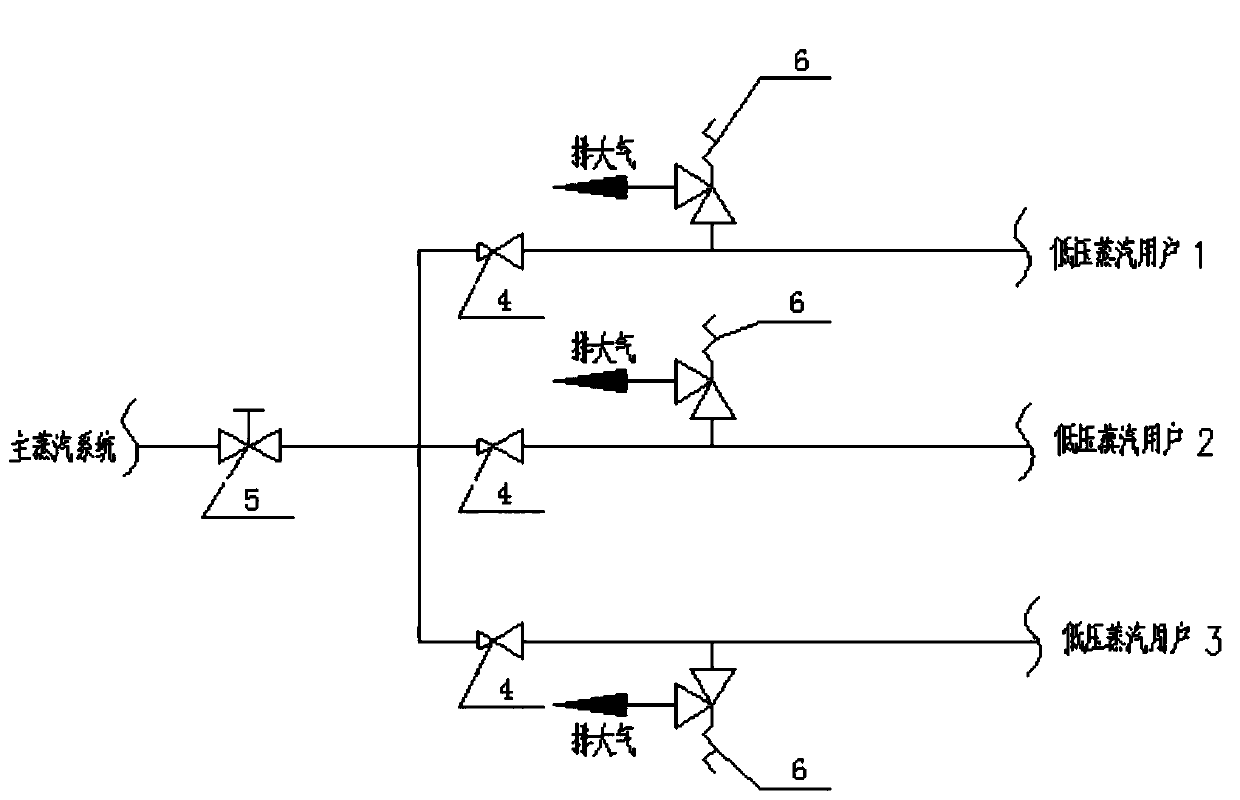

[0013] Such as figure 1 As shown, in the traditional decompression device, a stop valve and a safety valve are respectively installed on each branch connecting the main steam main pipe and the low-pressure user, that is, the decompression device on the working steam branch of the low-pressure user is set independently. Although this design method can meet the requirements of low-pressure steam users, it complicates and increases the size of the auxiliary steam system. At the same time, since each branch is equipped with only one regulating valve and one safety valve, there is no equipment backup, which reduces the reliability of the system.

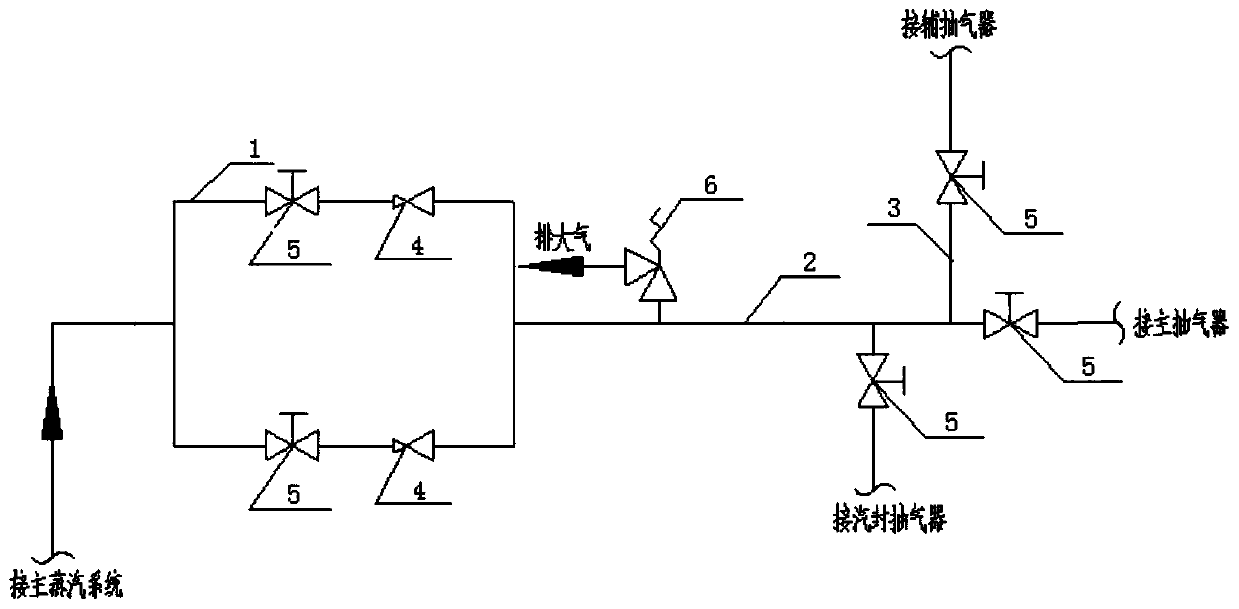

[0014] The new automatic decompression device provided by the present invention is a centralized decompression valve group, including a decompression pipeline a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com