Frozen confection composition

A technology for frozen desserts and compositions, which can be used in frozen desserts, food science, applications, etc., and can solve problems such as poor stability

Active Publication Date: 2020-07-14

UNILEVER IP HLDG BV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

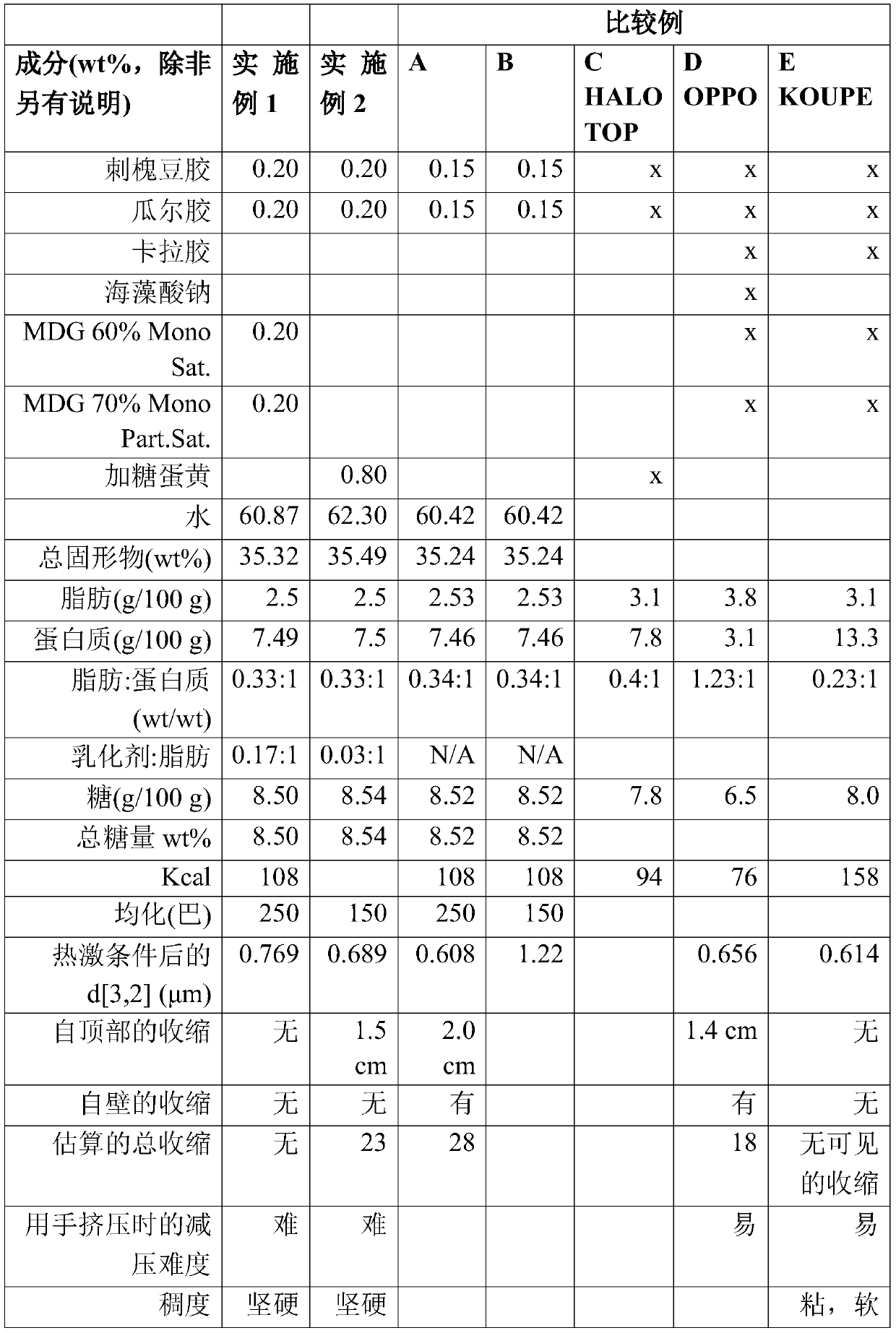

However, all three products were observed to have poor stability after exposure to heat shock conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0074] Example 1 shows that the emulsifier is 0.1-1.0wt%, the fat is 0wt% to 5wt%, and the ratio of fat to protein is less than 1:1; wherein the average fat droplets of the homogenized premix of the frozen dessert composition The fat droplet size d(3,2) is 0.6 μm or less, and 0.8 μm or less under heat shock conditions. No shrinkage was observed after heat shock conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Frozen confection composition comprising from 0 wt% to 5 wt% fat, from 0 wt% to 10 wt% protein, a fat to protein ratio of less than 1:1 and an emulsifier; wherein the fat droplets of the homogenised pre-mix of the frozen confection have an average droplet size d (3,2) of below 0.6 micron, and significantly reduced shrinkage of the product is observed on heat shock testing of the frozen confectionproduct.

Description

Technical field [0001] The present invention relates to a frozen dessert composition comprising 0wt% to 5wt% fat, 0wt% to 10wt% protein (fat to protein ratio is less than 1:1), and an emulsifier; wherein the homogenization of the frozen dessert The average droplet size d(3,2) of the fat droplets in the mixture is less than 0.6 microns, and the shrinkage of the product is observed to be significantly reduced during the heat shock test of the frozen dessert product. Background technique [0002] Conventional ice cream and related products contain a composition that usually contains 7-15wt% fat; 4-5wt% milk protein; 5-7wt% lactose; 12-16wt% other sugars; about 0.5wt% The stabilizer, emulsifier and flavoring agent. The total amount of solids is usually 28-40 wt%, and the water content is 60-72 wt%. "The Science of Ice Cream", C. Clarke, RSC 2004, p. 39. [0003] The shrinkage of frozen dessert products during storage may be caused by many factors, including pressure and temperature ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23G9/32A23G9/38A23G9/44

CPCA23G9/32A23G9/38A23G9/44A23G9/327A23G9/34A23V2002/00

Inventor J·E·弗里曼M·麦克法兰

Owner UNILEVER IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com