Attachment magnetic pole for lifting magnet, lifting magnet having magnetic pole for hoisting steel material, method for conveying steel material, and method for manufacturing steel plate

A technology for lifting electromagnets and magnetic poles, which is applied in the direction of electromagnets, electromagnets, magnetic cores/yokes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

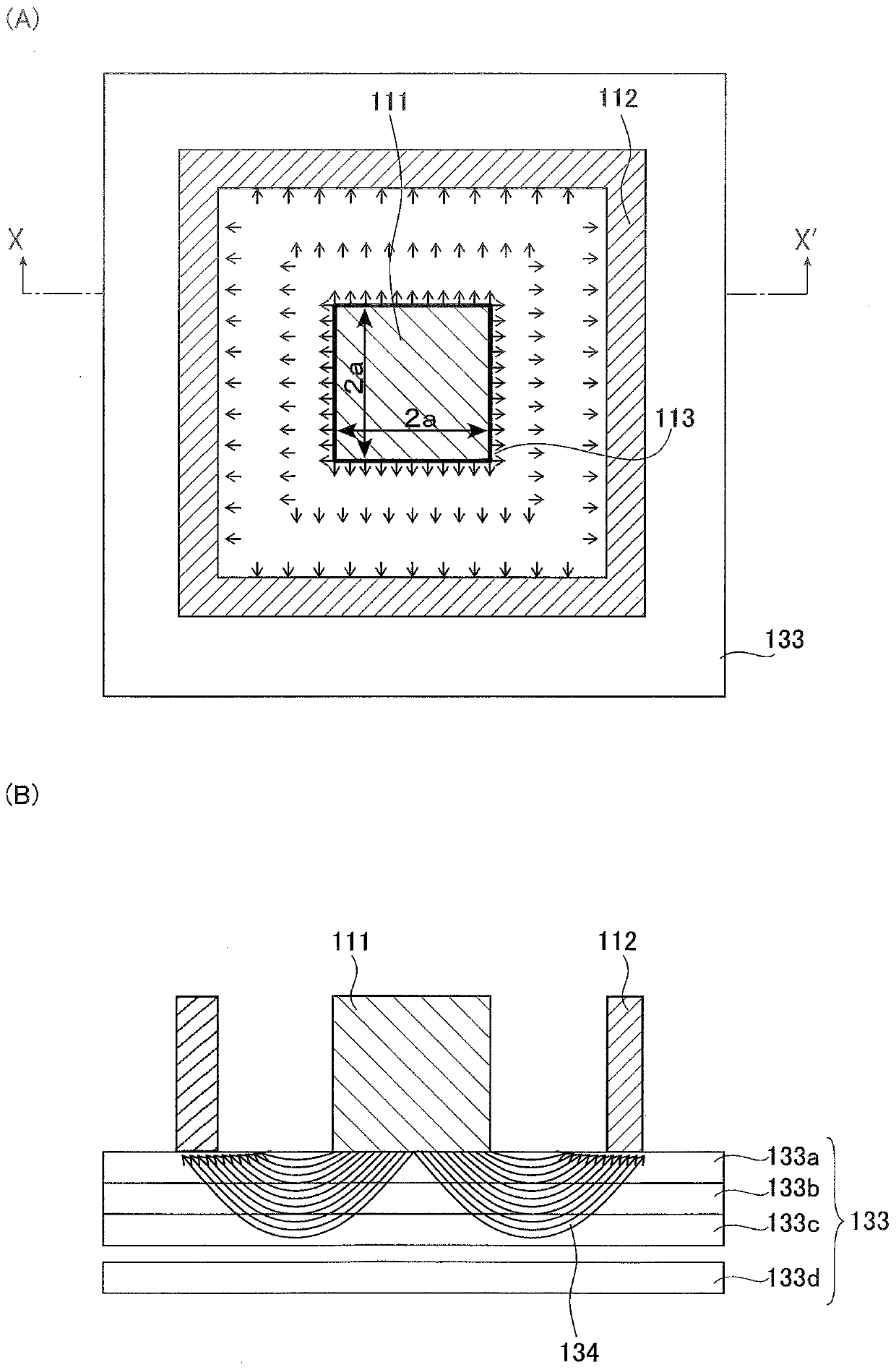

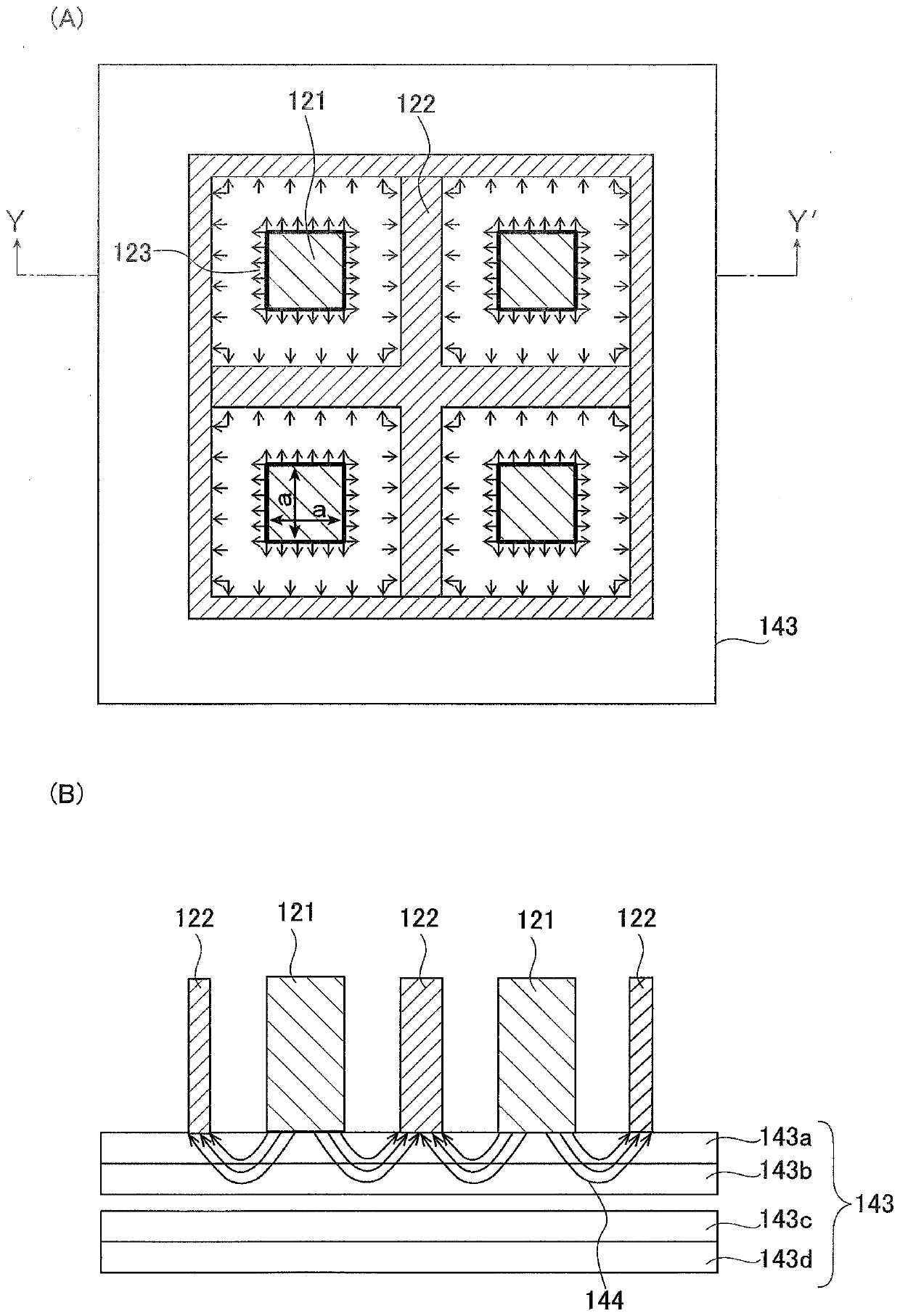

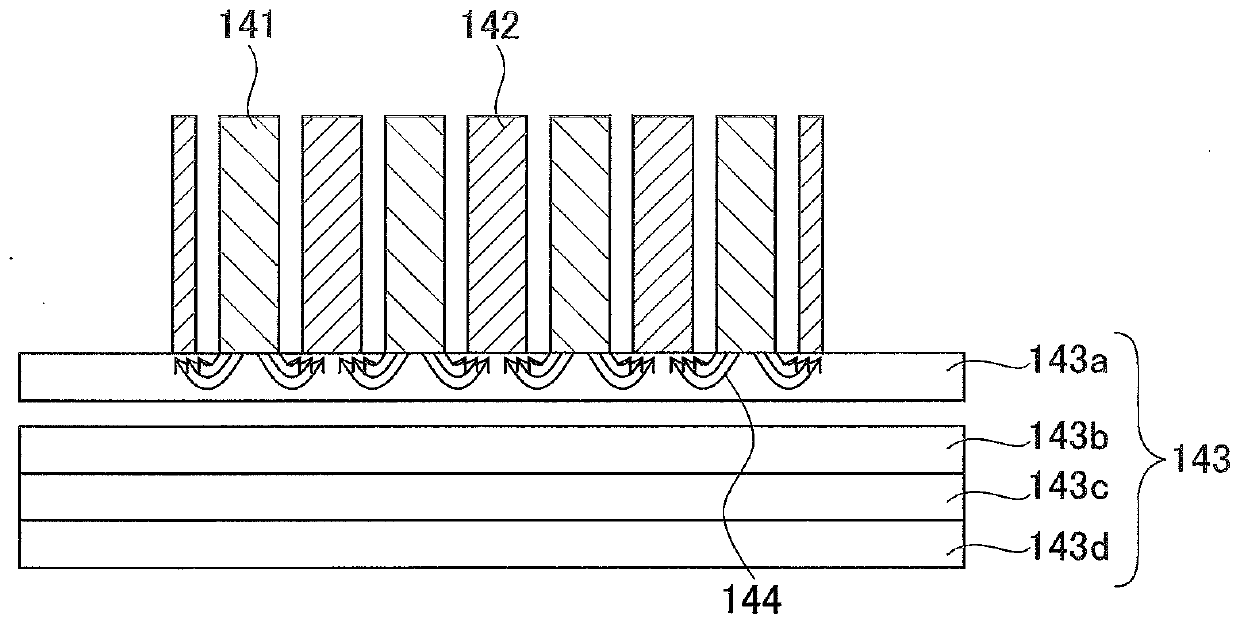

[0075] The mounting magnetic pole for a lifting electromagnet of the first embodiment is a mounting magnetic pole for a lifting electromagnet that lifts and transports a steel material by magnetic force, and has a magnetic pole that is in contact with the iron core of the lifting electromagnet and has a The first divided magnetic poles having a branched structure and the second divided magnetic poles having a branched structure contacting the yoke of the lifting electromagnet are arranged alternately. In addition, the size of the above-mentioned first divided magnetic pole may satisfy Expression (1) described later. Also, the interval between the alternately arranged first and second divided magnetic poles may be set to be 30 mm or less. In addition, the plate thicknesses of the above-mentioned first and second divided magnetic poles may be set to be 20 mm or less, respectively.

[0076] The lifting electromagnet with magnetic poles for lifting steel materials according to th...

no. 2 approach >

[0106] In addition to the basic structure of the above-mentioned first embodiment, the lifting electromagnet with the mounting magnetic pole for the lifting electromagnet and the lifting electromagnet with the magnetic pole for lifting the steel material of the second embodiment further have at least one movable magnetic pole, and The fixed magnetic pole is in the area adjacent to the movable magnetic pole and on the surface that is in contact with the steel material. In addition, the above-mentioned movable magnetic pole may be set as a movable type. In addition, the dimensions of the above-mentioned fixed magnetic poles may satisfy Expression (2) described later.

[0107] In the second embodiment of the present invention, as mentioned above, a lifting electromagnet with a magnetic pole is used to control the number of sheets of steel to be lifted such as only one piece of steel or only the target number of sheets (such as 2 ~3 sheets). The inventors of the present inventio...

Embodiment 1

[0165] Figure 7 It is a schematic diagram explaining the schematic structure of the attachment magnetic pole for lifting electromagnets in 1st Embodiment of this invention used in Example 1. Figure 7 (A) shows a plan view of the mounting pole for the lifting electromagnet viewed from below, Figure 7 (B) shown in Figure 7 D-D' line sectional view in (A), Figure 7 (C) shown in Figure 7 E-E' line sectional view in (A).

[0166] In Embodiment 1, as an example of the present invention, a lifting electromagnet (not shown) having an inner pole with a diameter of 150mm, a thickness of 60mm, and an outer pole with a size of 500mm×500mm is used. Figure 7 The shown lifting electromagnet of the present invention is used to install the magnetic pole (SS400 system) Figure 6 The lifting electromagnet with magnetic poles shown is used to carry out the lifting test of the steel plate. The thickness of the magnetic pole was set to 10 mm, and a gap of 20 mm was provided between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com