Bracket separating machine

A technology of separation machine and separation mechanism, which is applied in the direction of conveyors, conveyor objects, packaging, etc., can solve the problems of deformation of plastic pallets, achieve the effects of reducing occupied space, improving adsorption capacity, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

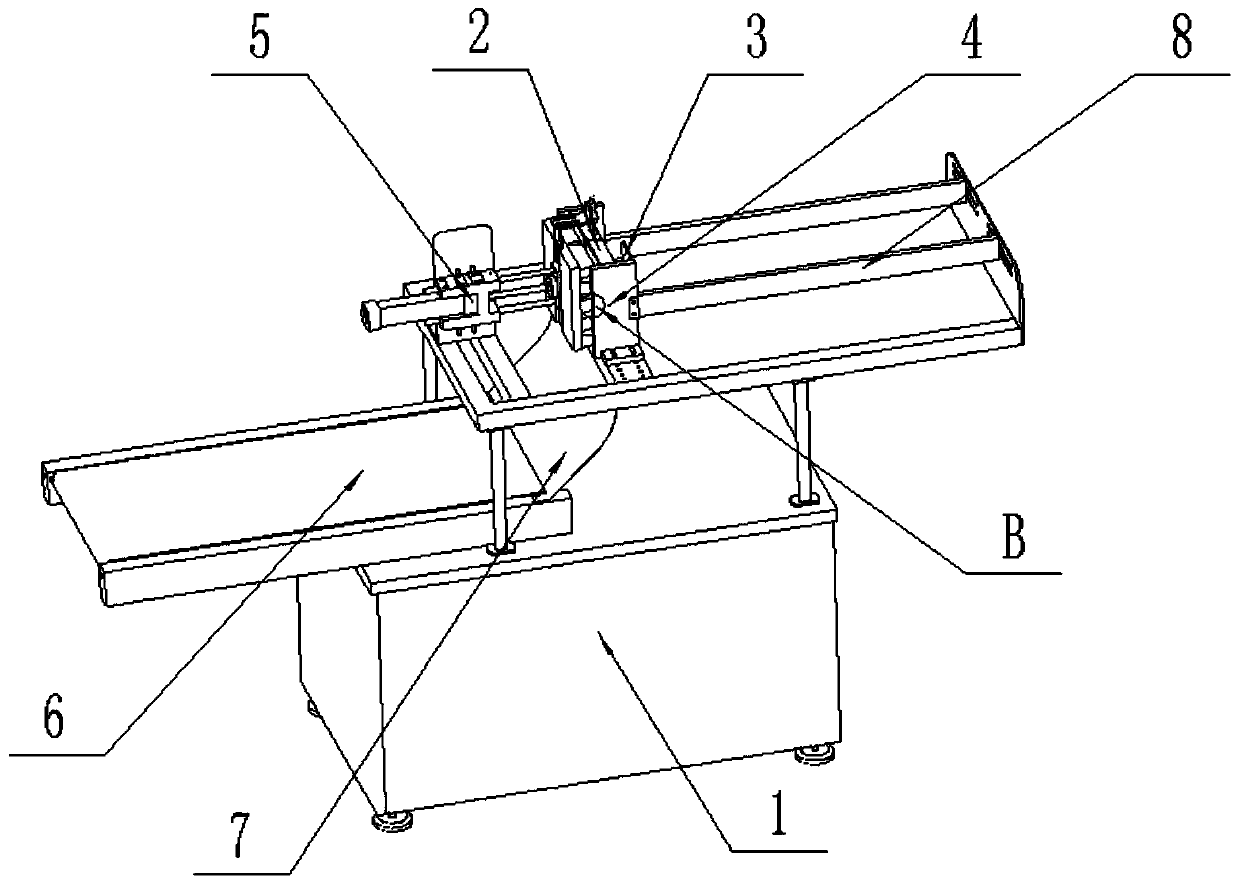

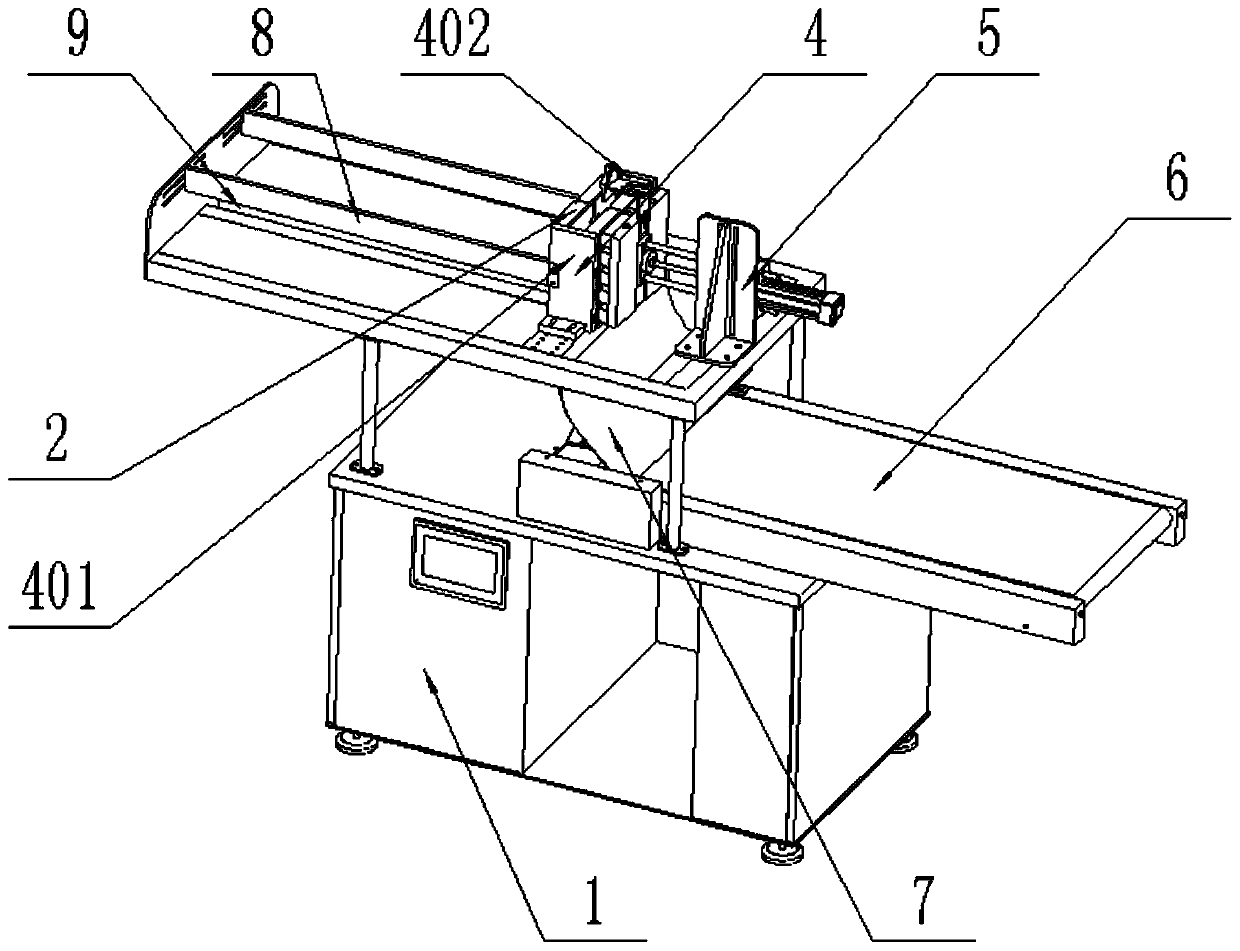

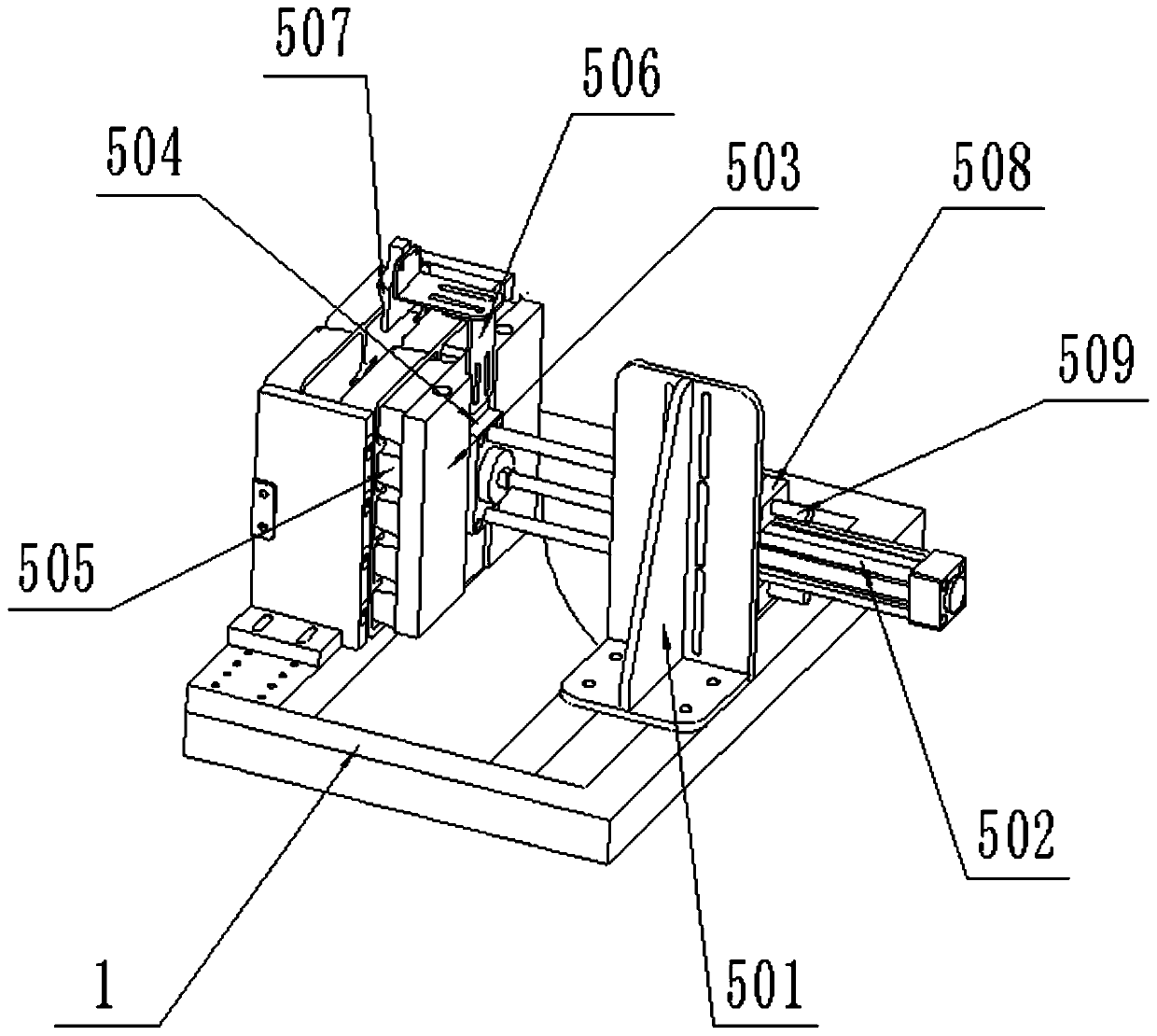

[0041] Such as Figure 1-12 As shown, a sorting machine includes a frame 1 on which a dodging mechanism 3, a tooth separation mechanism 4, a suction mechanism 5, and a box holder transmission device 6 are installed;

[0042] Dodging mechanism 3 comprises the upper supporting platform that is installed on the frame, and upper supporting platform 318 is provided with chute 9 along the direction of dodging, and push bracket 303 is installed movably in chute 9, and pushes bracket 303 tops and extends out chute installation. There is dodging plate 304, and dodging plate 304 is integrally formed into a flat plate to ensure the smoothness and strength of the pushing process; on the upper supporting platform 318, corresponding to the positions on both sides of the tooth separation mechanism 4, guard track plates 8 are installed along the dodging direction, during the dodging process Guide the box holder in the center. A guide rail 307 is installed on the bottom of the upper support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com