A kind of titanium quantum dot doped graphene-based conductive ink and its preparation method and application

A graphene-based, conductive ink technology, applied in the field of nanomaterials, can solve the problems of poor conductivity, uneven heating, poor stability of graphene ink, etc., and achieve the effects of outstanding economic value, strong practicability and long service life

Active Publication Date: 2022-05-31

FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

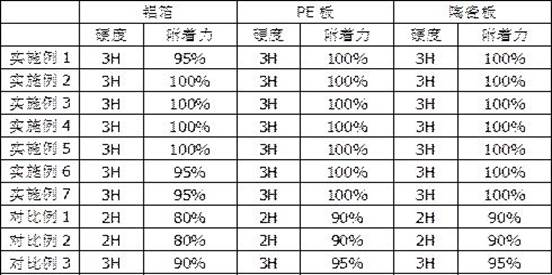

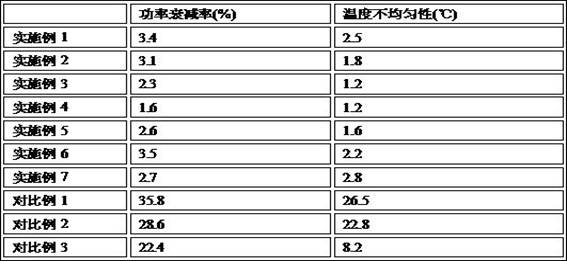

[0005] In view of this, the present invention provides a kind of titanium quantum dot doped graphene-based conductive ink, to solve the poor stability of graphene ink existing in the prior art, the thickness of graphene ink printing layer is difficult to control, poor conductivity, The conductive film formed after printing is prone to brittleness, aging, and uneven heating after long-term use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to view more

Abstract

The invention provides a graphene-based conductive ink doped with titanium quantum dots, comprising the following components in parts by weight: 15-40 parts of graphene dispersion liquid of 5-150 mg / mL, 5-80 mg / mL of titanium quantum dots 40-120 parts of dot dispersion liquid, 5-25 parts of conductive carbon black, 0.5-2.5 parts of polyacrylonitrile-maleic anhydride copolymer, 0.5-2.5 parts of structural stabilizer, 100-500 parts of first dispersant, 2nd dispersion 50 to 200 parts of agent, 5 to 20 parts of peeling resin, and 5 to 10 parts of leveling agent. The graphene conductive film prepared by the titanium quantum dot-doped graphene-based conductive ink of the present invention has considerable flexibility, toughness, hardness and adhesion, can be printed on various substrates, and has the characteristics of high temperature resistance, long service life and the like . The invention also provides a preparation method of the titanium quantum dot doped graphene-based conductive ink and its application in preparing the graphene conductive film.

Description

A kind of titanium quantum dot doped graphene-based conductive ink and its preparation method and application technical field The present invention relates to the technical field of nanomaterials, be specifically related to a kind of titanium quantum dot doped graphene-based conductive ink, The invention also relates to the preparation method of the titanium quantum dot doped graphene-based conductive ink and the method for preparing the graphene conductive film. application on. Background technique Graphene is a kind of hexagonal honeycomb lattice structure formed by carbon atoms through sp2 hybrid orbital and has only one layer. Two-dimensional nanomaterials with the thickness of carbon atoms. The unique structure of graphene endows it with many excellent properties, such as high theoretical specific surface area (2630m 2 / g), ultra-high electron mobility (~200000cm 2 / v.s), high thermal conductivity (5000W / m.K), high Young's modulus (1.0TPa) and high tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C09D11/52C09D11/30C09D11/38C09D11/107C09D11/03C09D11/102C09D11/105C09D11/103B41M1/02B41M1/12B41M1/30B41M1/28B41M1/34B41M5/00B05D1/00B05D1/28D01D5/00D04H1/728D04H3/02

CPCC09D11/52C09D11/30C09D11/38C09D11/107C09D11/03C09D11/102C09D11/105C09D11/103B41M1/02B41M1/12B41M1/30B41M1/28B41M1/34B41M5/0047B41M5/0058B41M5/0064B41M5/007B05D1/005B05D1/28D04H1/728D04H3/02D01D5/0084D01D5/003Y02P70/50

Inventor 吴立刚叶德林胡柱东彭令曾垂彬孔金波刘秋明马宇飞

Owner FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap