Self-cleaning method for full-automatic roller washing machine

A drum washing machine and self-cleaning technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of secondary pollution of clothes, incomplete cleaning effect, easy neglect of self-cleaning function, etc., and achieve the effect of health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

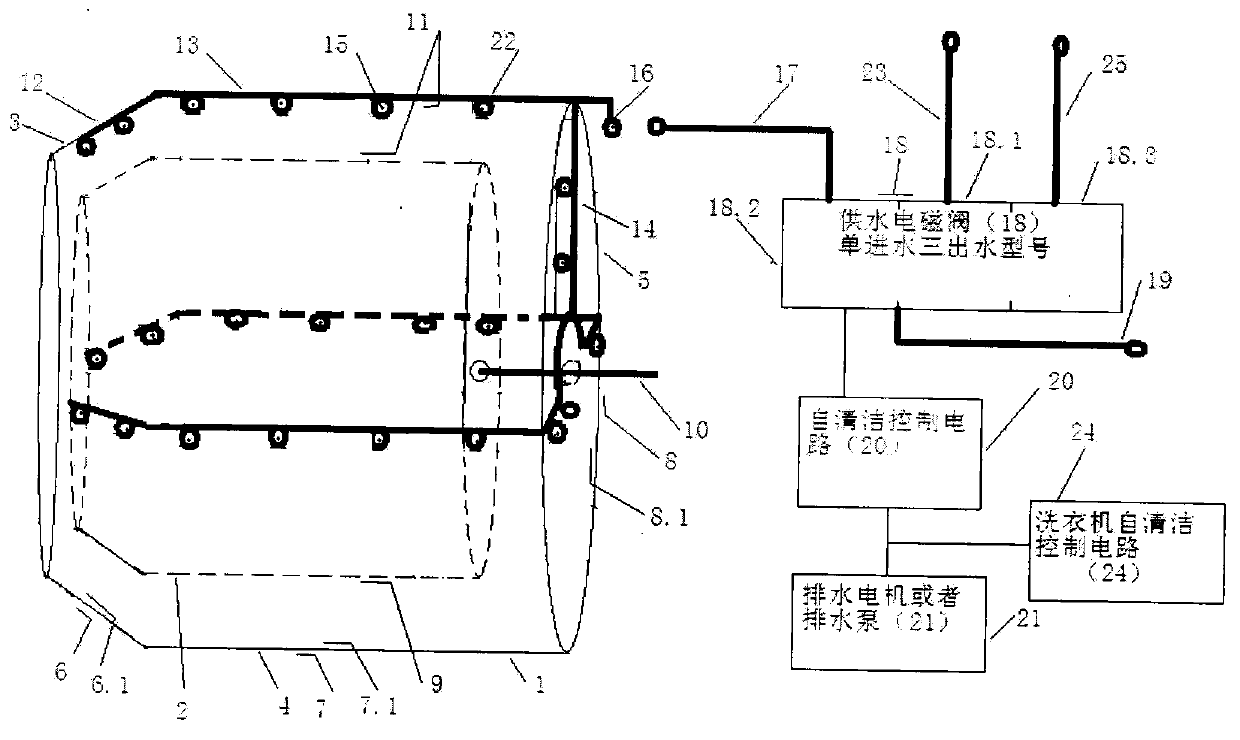

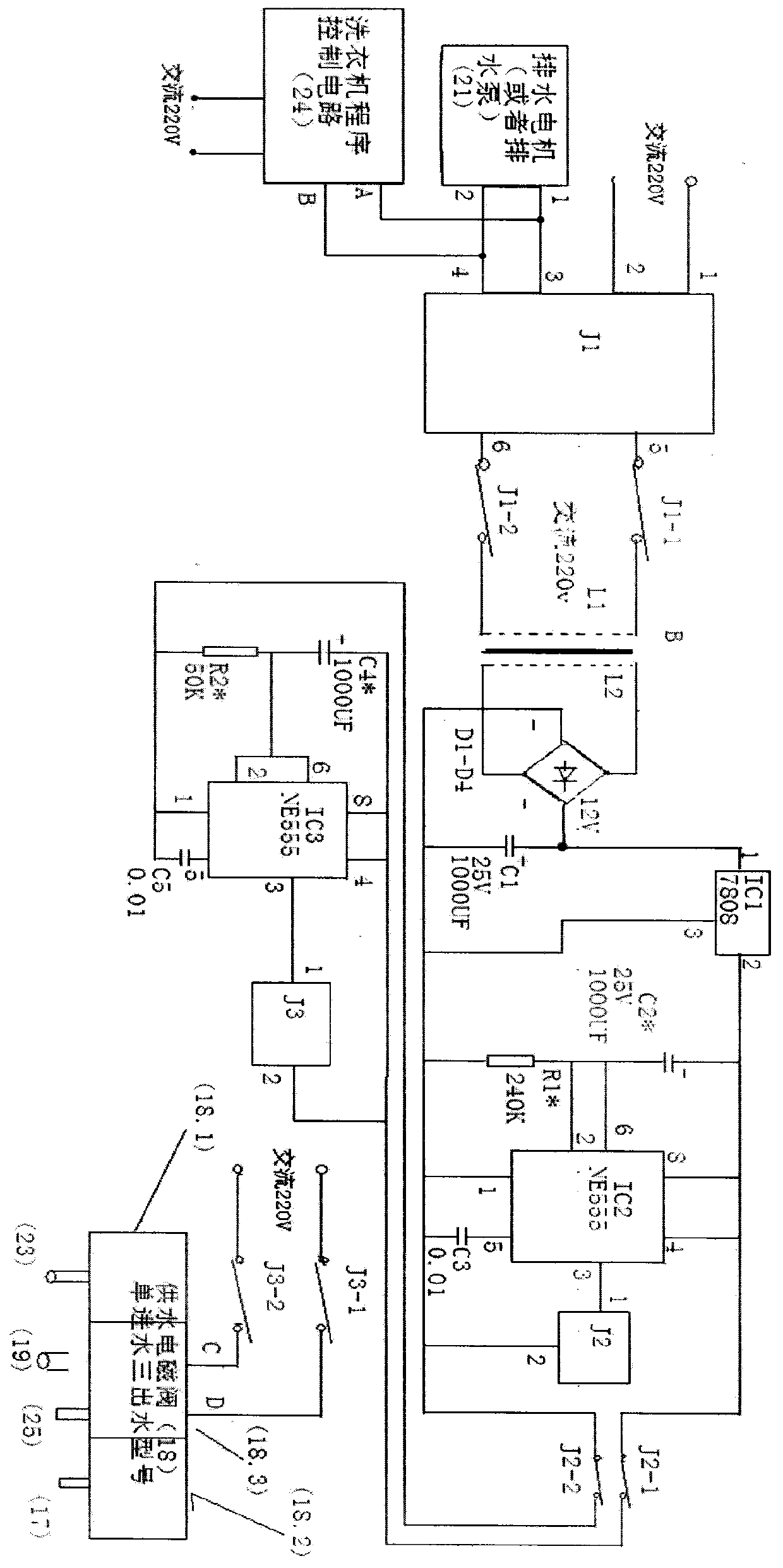

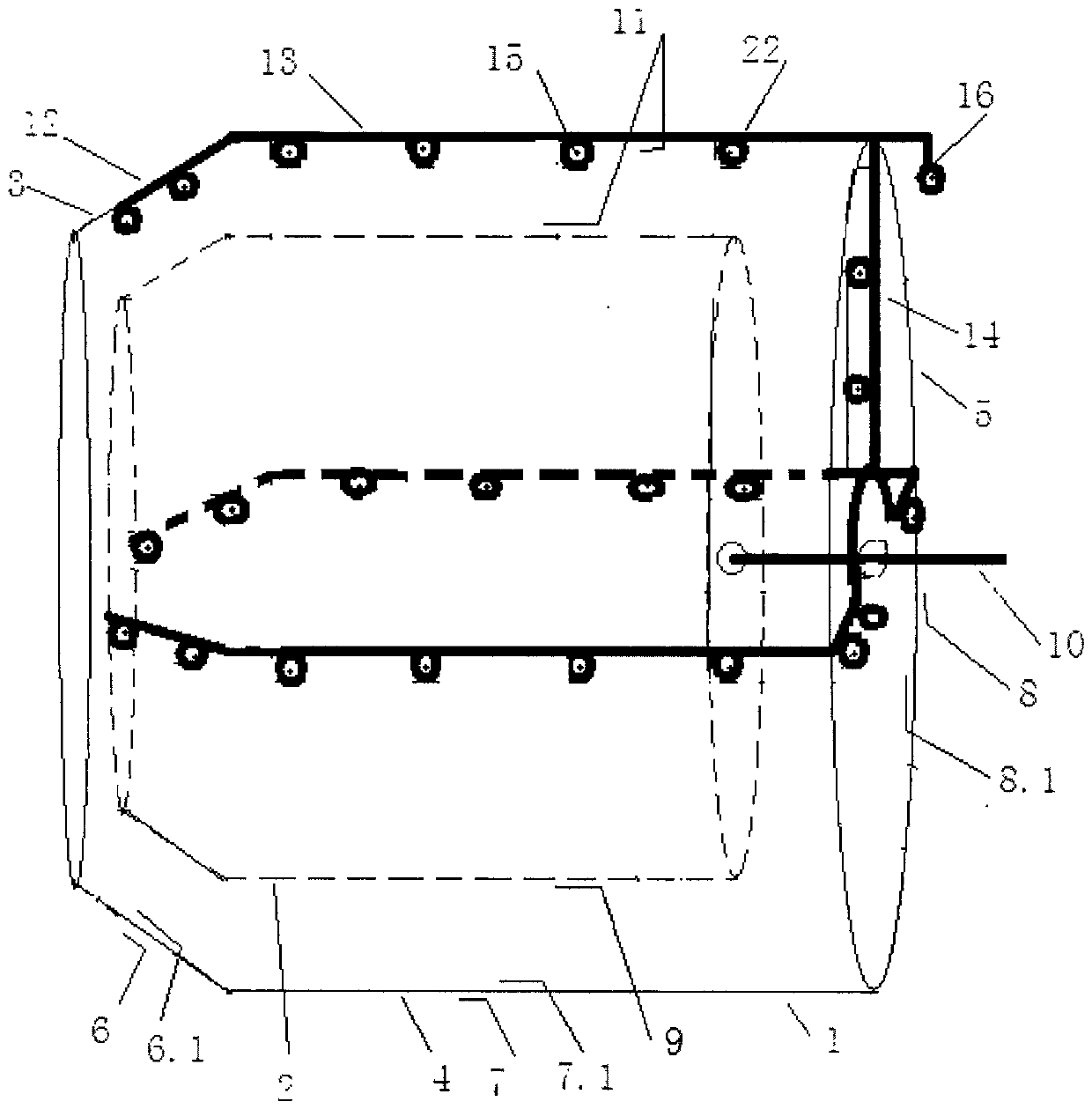

[0020] figure 1 , figure 2 , image 3 , Figure 4Among them, after the program control circuit (24) of the fully automatic self-cleaning drum washing machine enters the dehydration program, the drain motor (or drain pump) (21) of the washing machine is sent to the 1, 2 pins of the drain motor (or drain pump) (21) of the washing machine and the coil of the relay J1 at the same time through the (A, B) line. 3, 4 pins supply power, the drainage motor (or drain pump) (21) of the washing machine starts to discharge the washing sewage, and at the same time, the coil 3 and 4 pins of the relay J1 generate current at both ends, at this time J1-1 and J1-2 are closed, and the relay J1 The 220V voltage of pins 1 and 2 is sent to the primary coil L1 of the 12V transformer B through the 5 and 6 pins, and the 220V AC voltage is changed to 12V AC voltage through the 12V transformer B, which is sent to the (D1-D4) by the secondary pole coil L2 The rectification circuit is composed of 12V D...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap