Variable cross-section hollow thin-wall pier telescopic steel bar jig frame and jig frame set

A hollow, thin-walled, telescopic technology, which is applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the difficulty of controlling the distance between steel bars and the control of steel bar cover, the difficulty of controlling the overall size of the steel bar skeleton, and the unsatisfactory construction process, etc. problems, to achieve the effect of improving the qualified rate of binding, effectively controlling the construction quality, and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the embodiments of the present invention more clearly, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

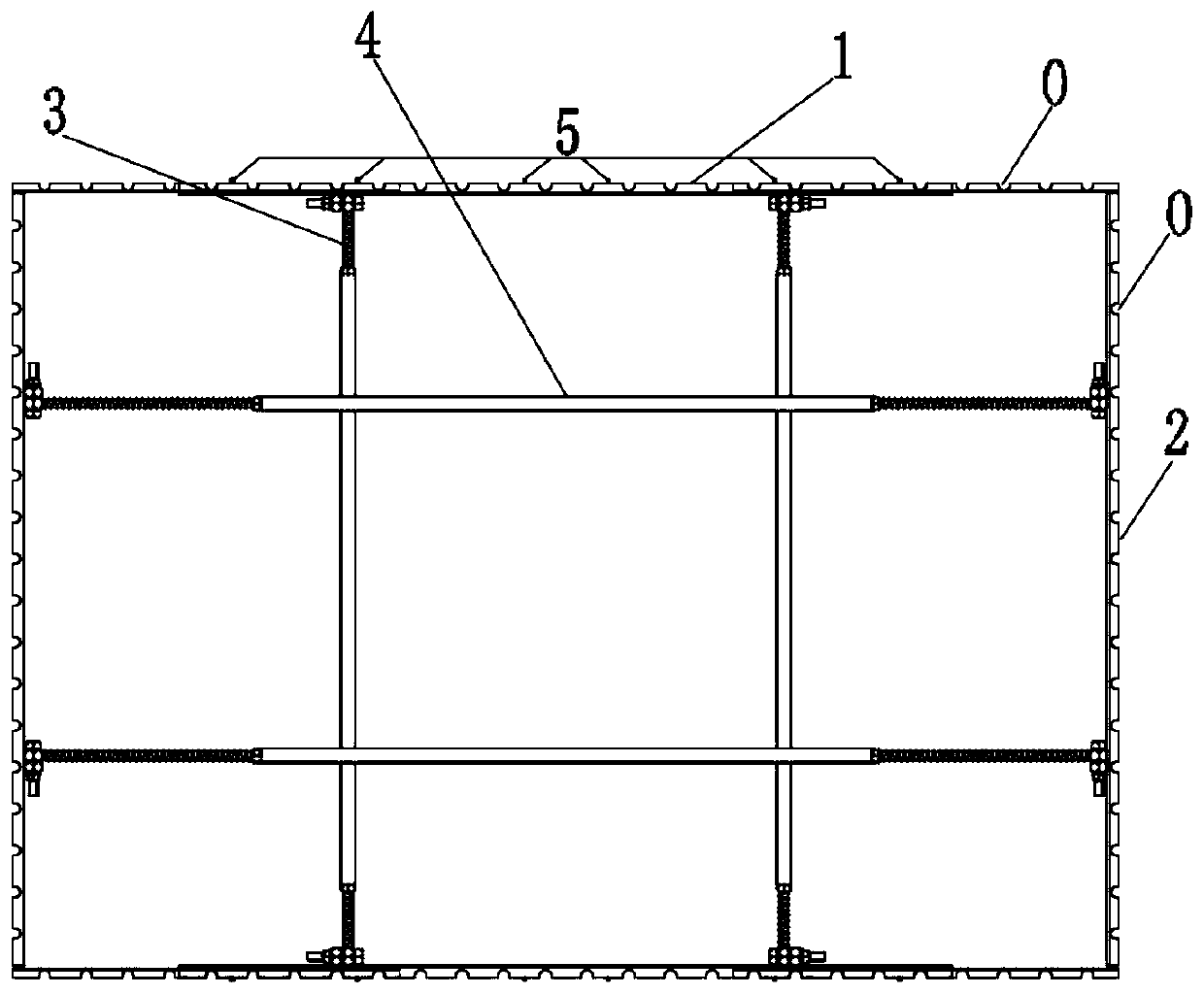

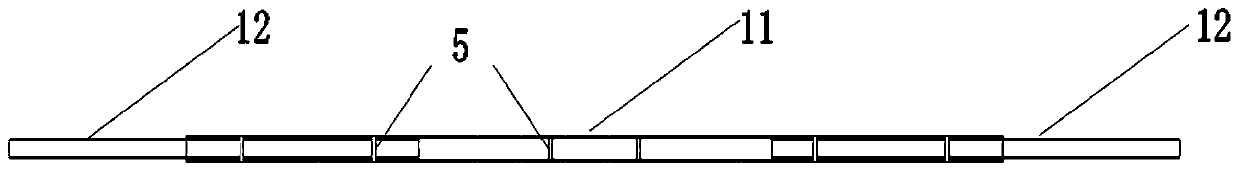

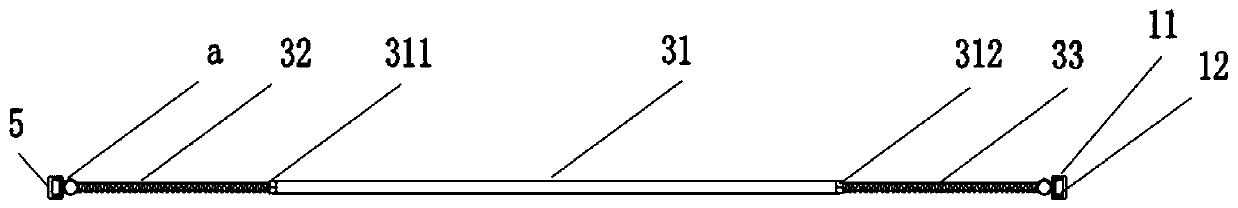

[0025] Such as Figure 1-5 As shown, the variable-section hollow thin-walled pier telescopic reinforced tire frame of the embodiment of the present invention includes two long-side formworks 1, two short-side formworks 2, two first distance-adjusting components 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com