Mechanical replacement type mine explosion door

A technology for explosion-proof doors and mines, which is used in the ventilation of mines/tunnels, mining equipment, and earth-moving drilling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

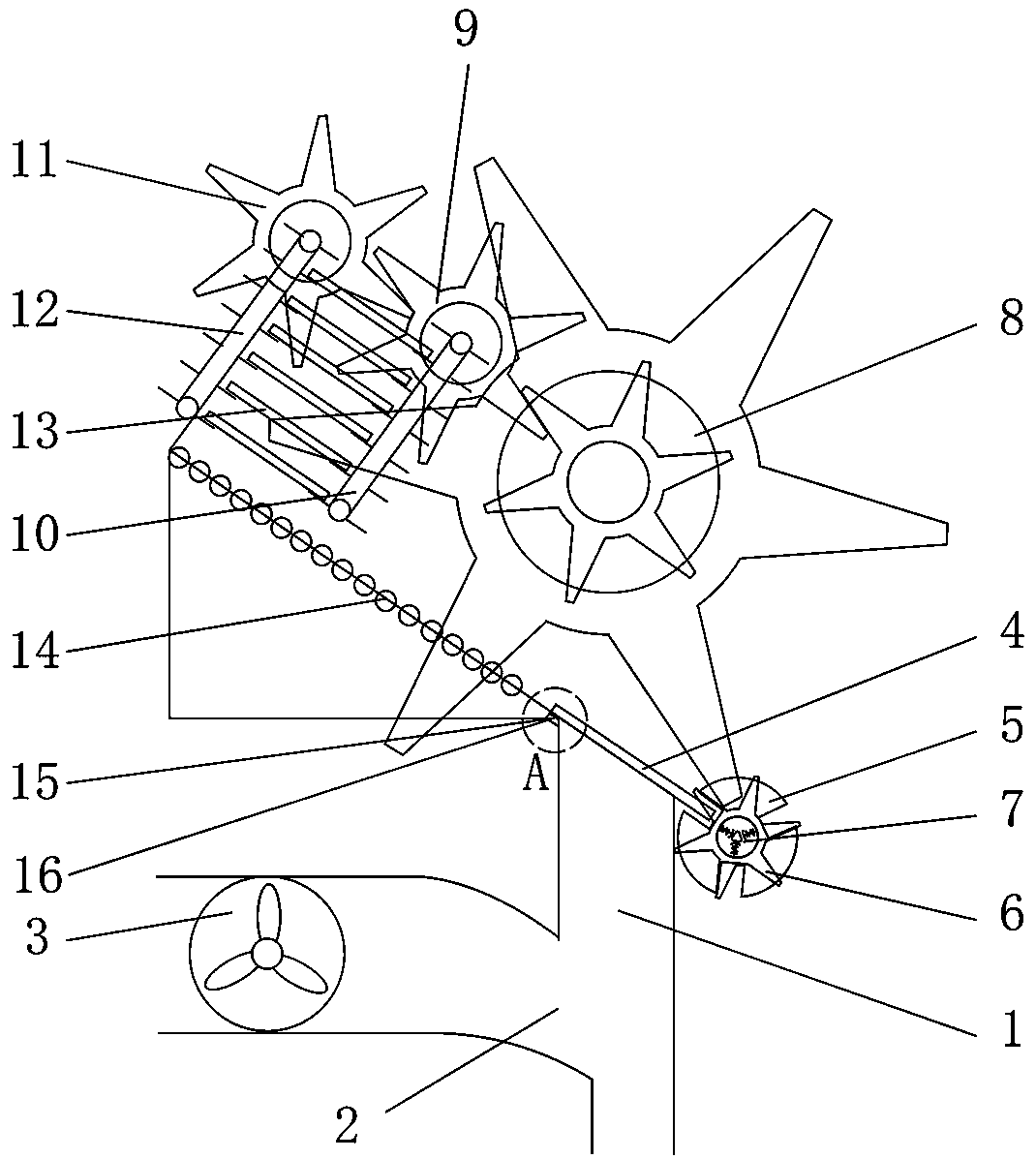

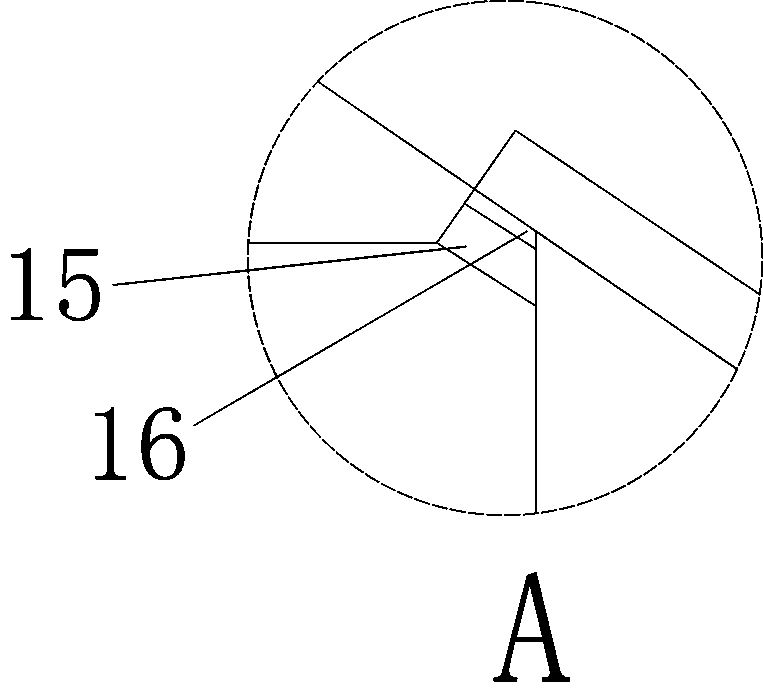

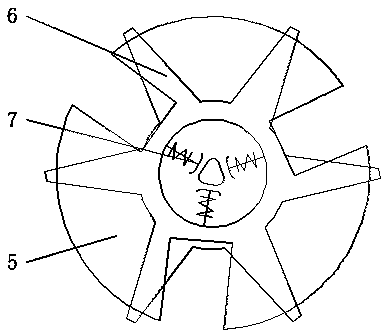

[0022] see Figure 1 to Figure 4 , the present invention is a mechanically replaceable mine explosion-proof door, comprising an explosion vent 1, the left side of the explosion vent 1 is connected with a fan port 2, the inside of the fan port 2 is provided with a fan 3, and the explosion vent 1 gradually Widening, by designing the explosion vent 1 to gradually widen from bottom to top, to a certain extent, the shock wave generated by the explosion is prevented from entering the fan port 2, preventing damage to the fan 3, and protecting the safety of the fan 3. The explosion vent 1 changes from narrow to wide, which has a certain weakening effect on the shock wave. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap