Centrifugal water diversion device and implementation method thereof

A realization method, centrifugal technology, applied in the direction of non-variable pumps, pump control, driving pumps, etc., can solve the problems of abnormal drainage, water leakage, shortened service life of centrifugal pumps, etc., to avoid flameout shutdown and irrigation operations, The effect of ensuring the service life and reducing the working intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

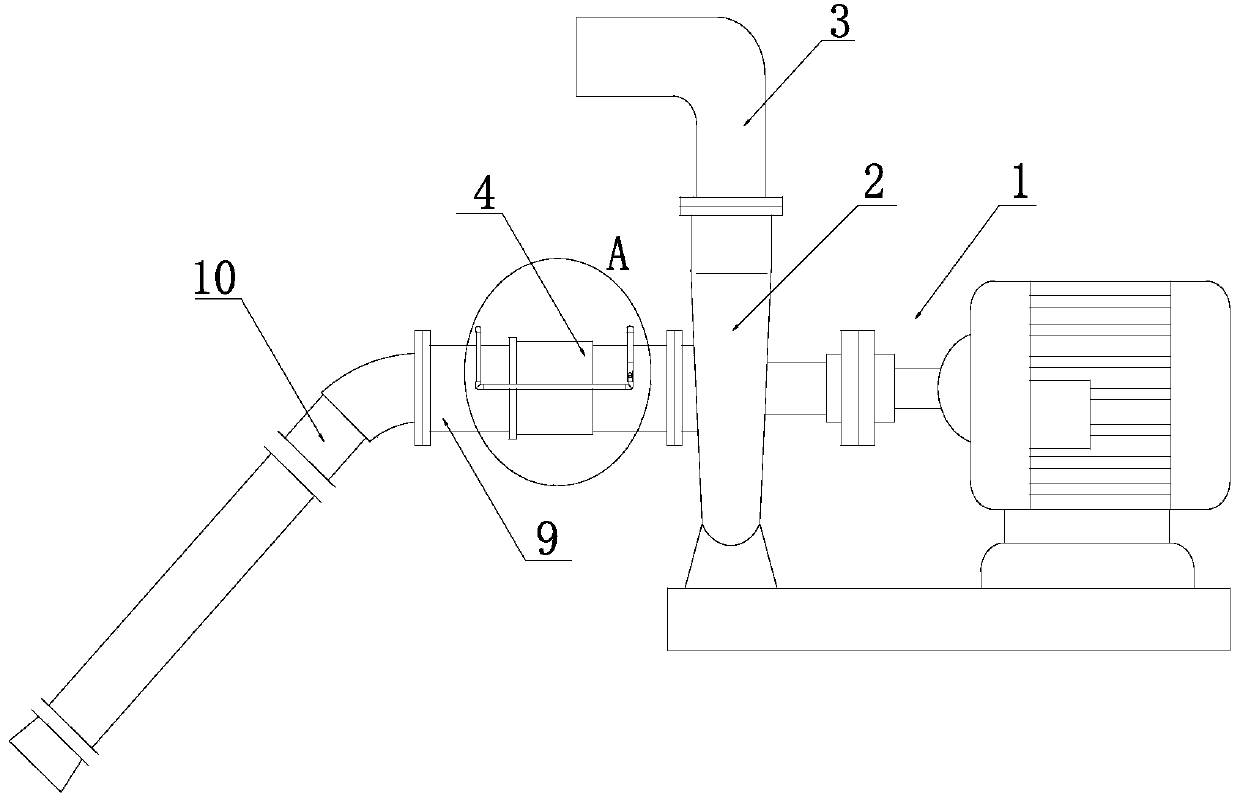

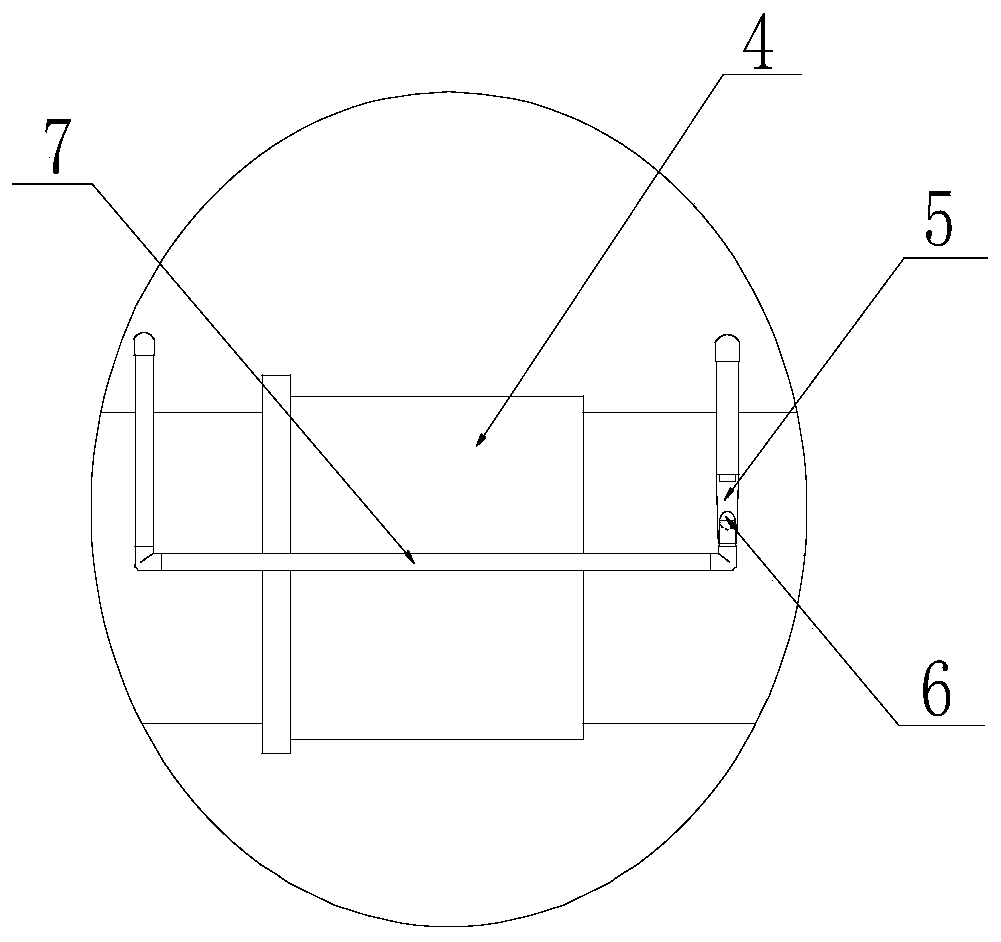

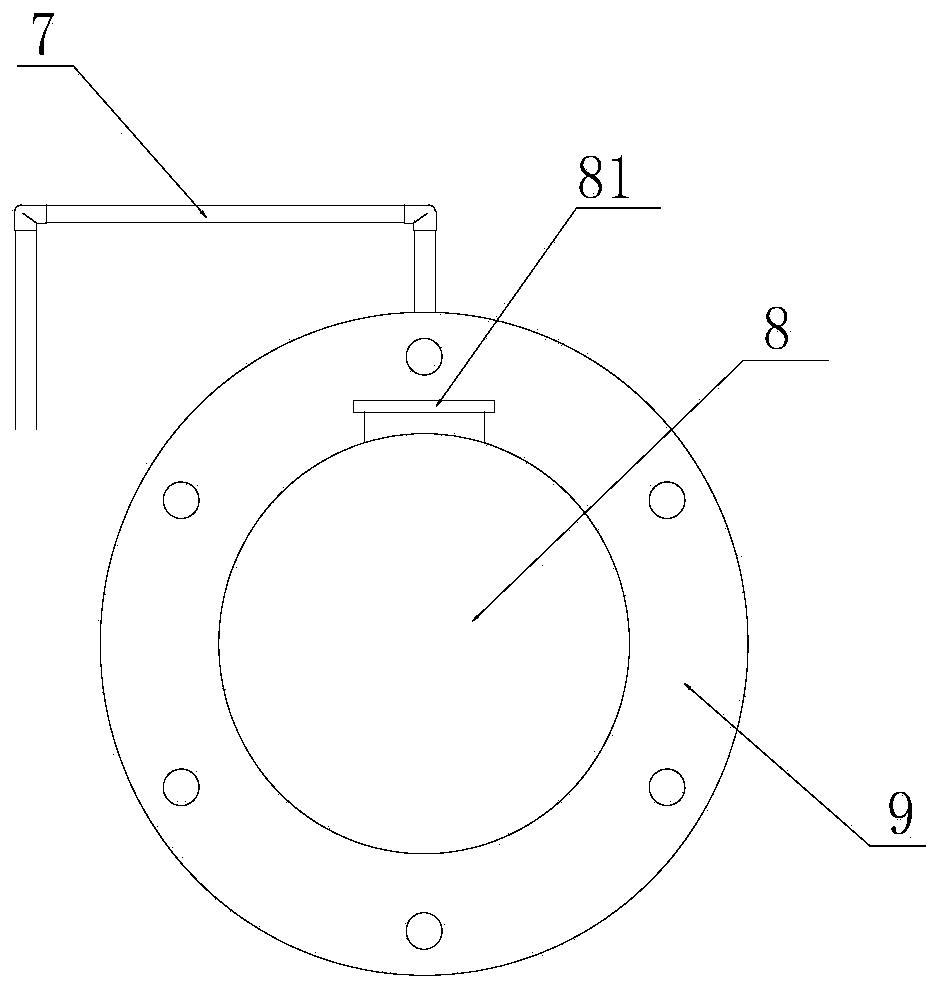

[0047] The invention provides a water diversion device, which is used in conjunction with a centrifugal pump to realize groundwater pumping and drainage. Such as Figure 1~4 As shown, the present invention mainly includes centrifugal pump 1, water injection pumping mechanism and water pumping pipeline 10 three major parts structurally, wherein, described water injection pumping mechanism is the core part of the whole scheme, and it comprises one end through a 45 ° elbow The first flange pipe 9 connected to the suction pipe 10, the second flange pipe 4 connected to the first flange pipe 9 at one end and the pump casing 2 of the centrifugal pump 1 (the pump casing is connected with the outlet pipe 3) at the other end , the check valve 8 that is arranged near the junction of the first flange pipe 9 and the second flange pipe 4 and can be reversed (the check valve 8 is connected with the end of the first flange pipe 9 through a rotating shaft 81, such as image 3 shown), and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com