A textile printing and dyeing drying equipment with auxiliary heating function

A textile printing and dyeing and auxiliary heating technology, which is applied in lighting and heating equipment, heating devices, drying, etc., can solve the problem of insufficient heating of the lower surface of the cloth, and achieve simple and efficient heat conduction structure, high heat conduction and heating efficiency, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

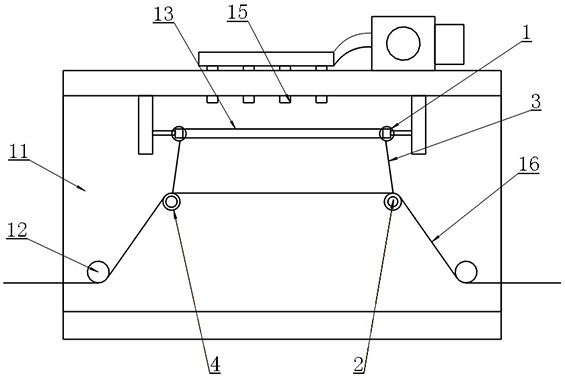

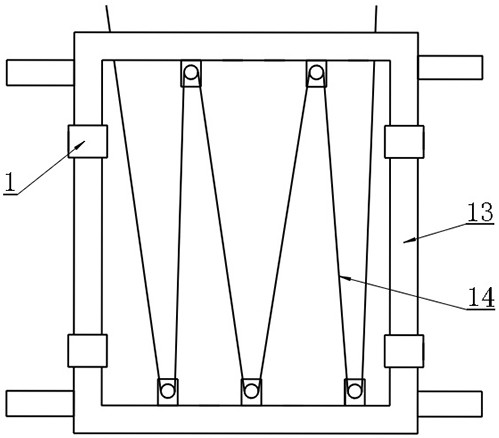

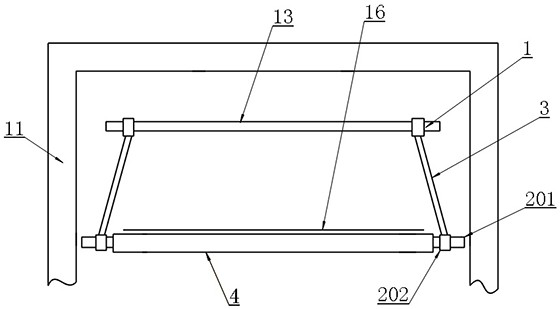

[0024] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Image 6 As shown, a textile printing and dyeing drying equipment with auxiliary heating function includes a drying box 11, a lower pressure roller 12 arranged in the drying box 11, and an installation frame 13, which are arranged in the installation frame The electric heating wire 14 in the body 13, and the downward blowing pipe 15 arranged on the drying box 11, also includes a pair of heat conduction rings 1 which are sleeved on the installation frame 13, and are arranged on the The heat conduction ring 1 and the heat conduction strips 3 used for the suspension operation at both ends of the heat conduction column unit 2, and the heat conduction strips 3 that are set on the heat conduction column unit 2 and are used to be used on the cloth 16 by jacking up. A heating cylinder 4 for auxiliary heating on the lower surface.

[0025] In this embodiment, the electric heating wire 14 is externally connected to a pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com