Coal caking index and gelatinous layer index rapid measurement method

A colloidal layer index and cohesion index technology, applied in the field of atomic emission spectrometry, can solve the problems of slow speed, insufficient measurement accuracy, and only offline measurement, etc., to achieve improved measurement accuracy, obvious matrix effect, and unrepeatable high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

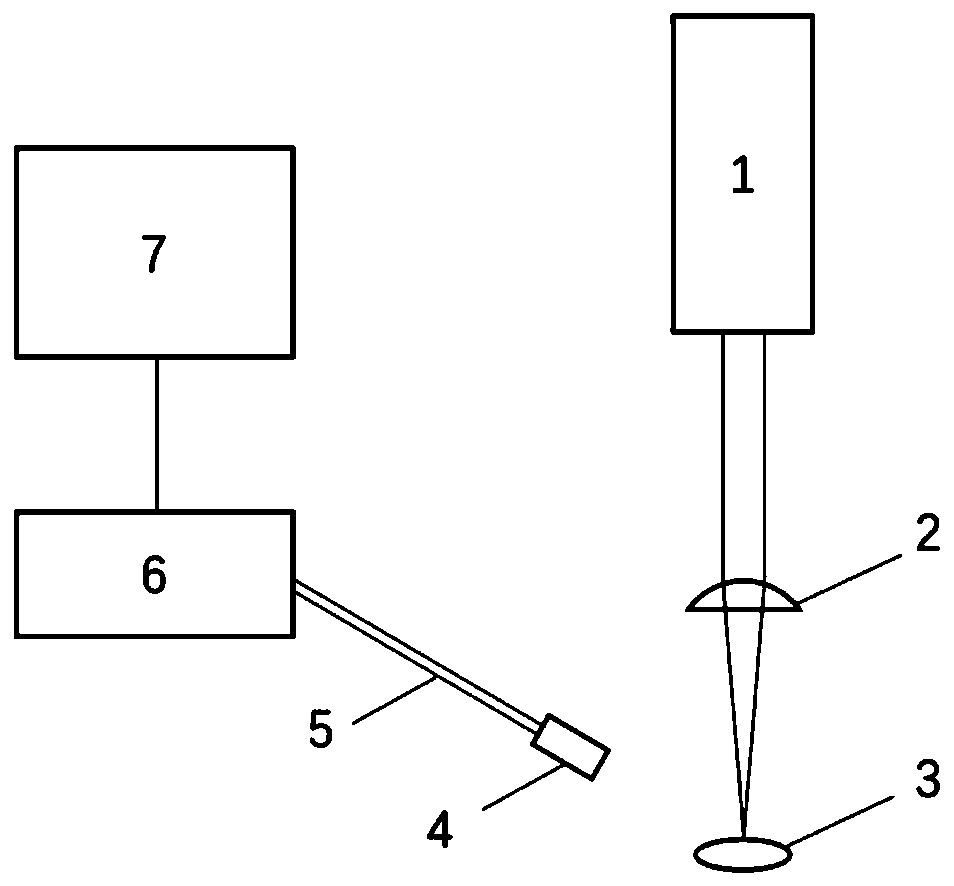

Method used

Image

Examples

Embodiment

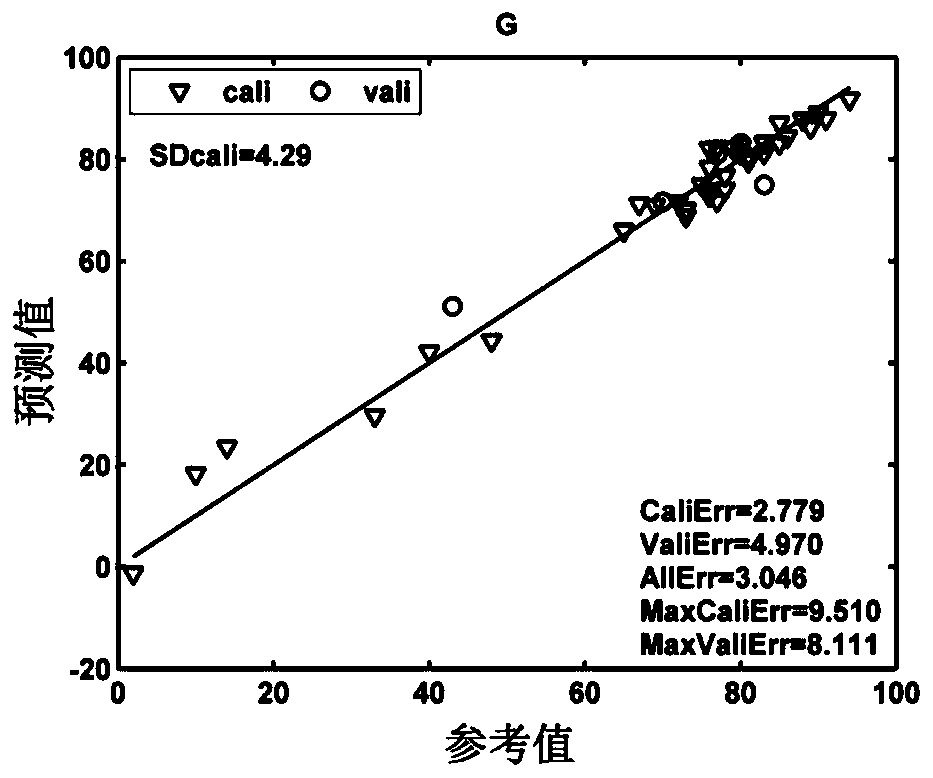

[0056] Implementation example: measurement of cohesion index and colloidal layer index on 40 coal samples

[0057] 1) In this example, a total of 40 coal samples were used, 35 samples were selected as calibration samples, and the remaining 5 samples were used as samples to be tested; As a reference value, as shown in Table 1; due to the large amount of data, some sample data are omitted here;

[0058] Table 1. Calibration sample composition

[0059]

[0060]

[0061] 2) Use the LIBS system to collect the spectral data of 35 calibration samples to obtain the spectral line intensity;

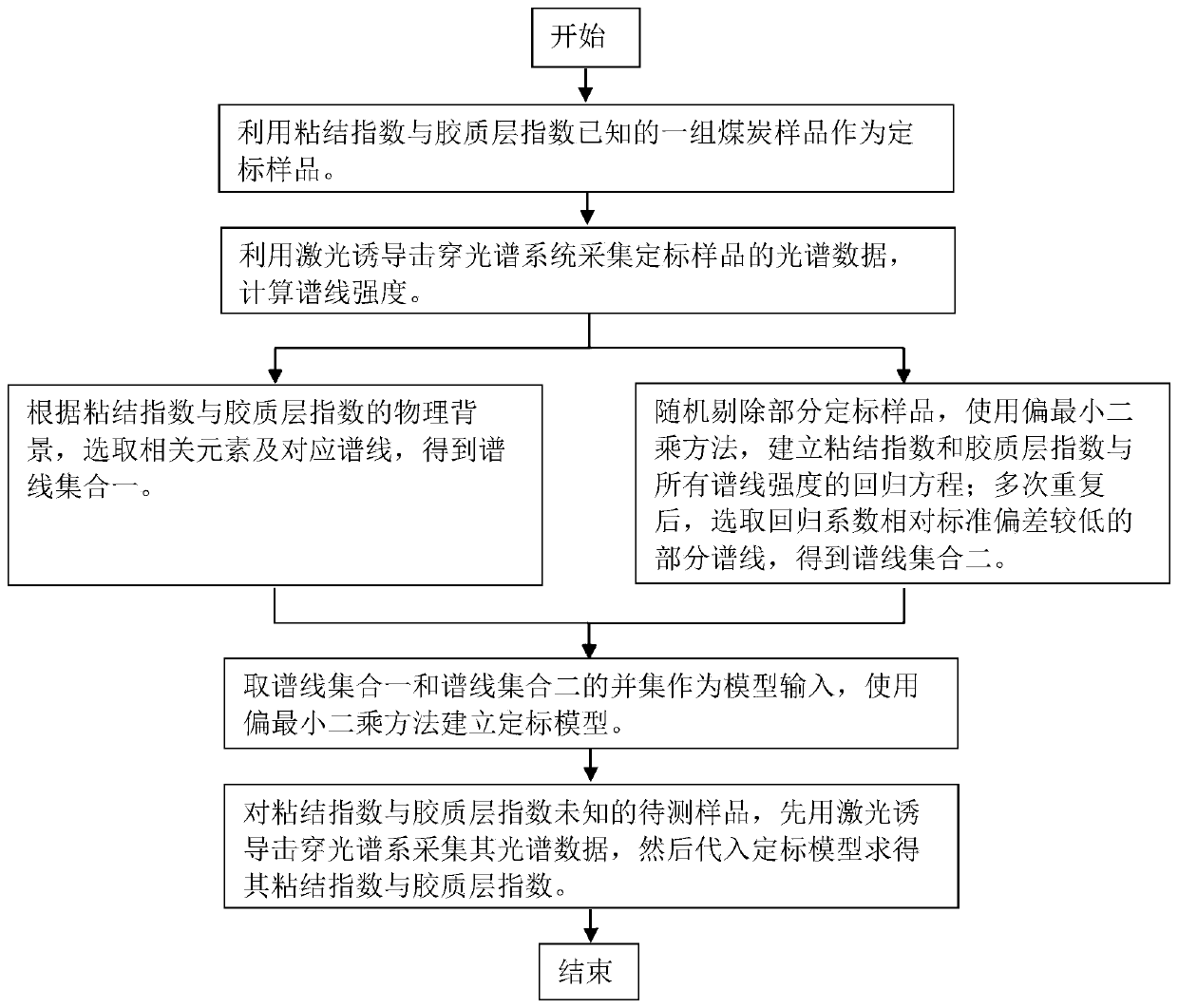

[0062] 3) Screen the spectral lines and use the PLS method to establish a calibration model:

[0063] a) According to the physical background, select the atomic wires and ionic wires of carbon, nitrogen, silicon, oxygen, and aluminum, as well as CN, C 2 Molecular line, get spectral line set 1;

[0064] b) Randomly remove 5 of the 35 calibration samples, and use the PLS method to establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com