Winding distribution coefficient calculation model and method considering motor slot conductor distribution difference

A technology of distribution difference and winding distribution, applied in the field of electromechanics, can solve the problems of unsatisfactory motor control effect, deviation of physical model, unfavorable formation of basic theory and technical system of high-quality servo motor system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

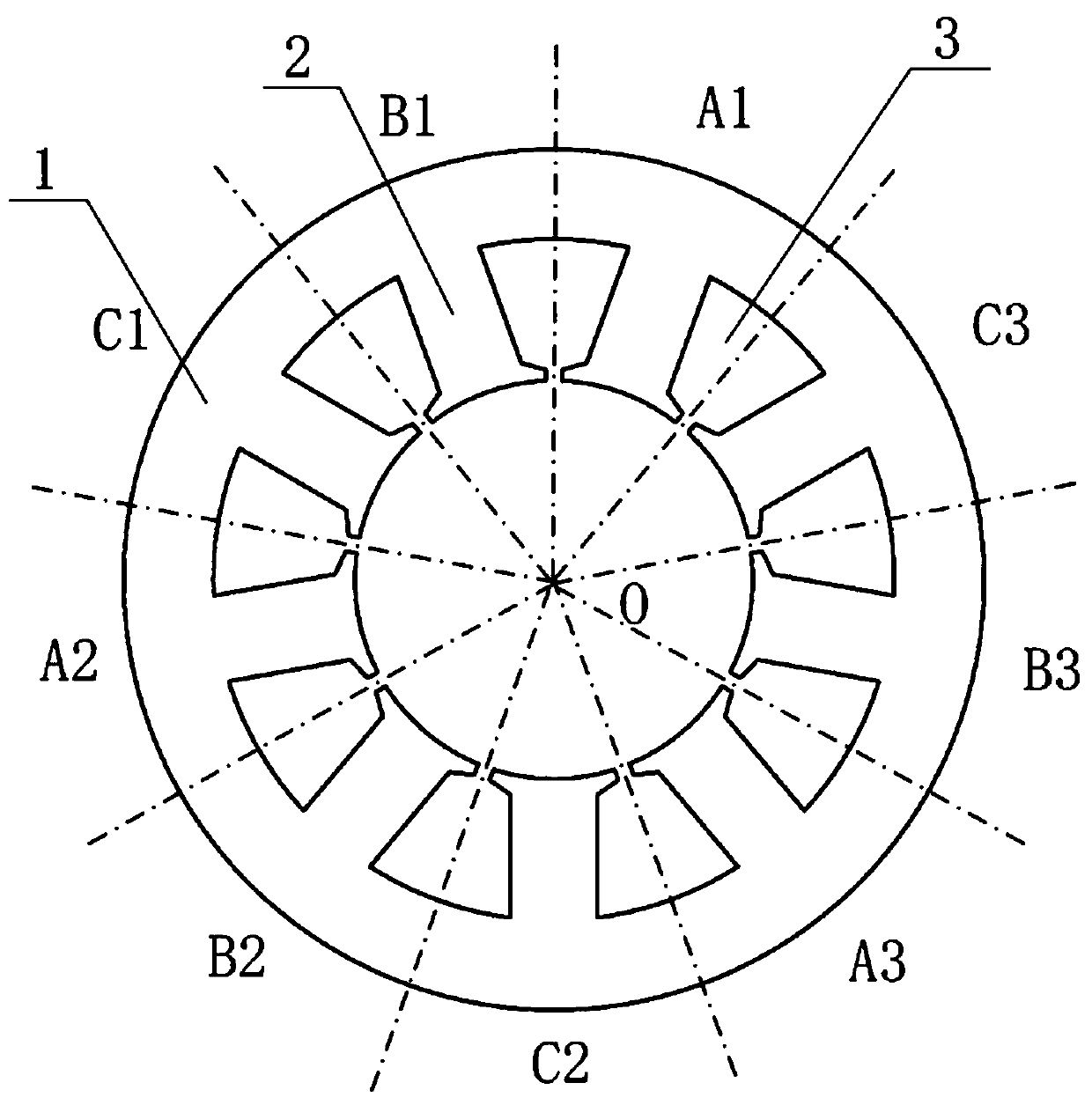

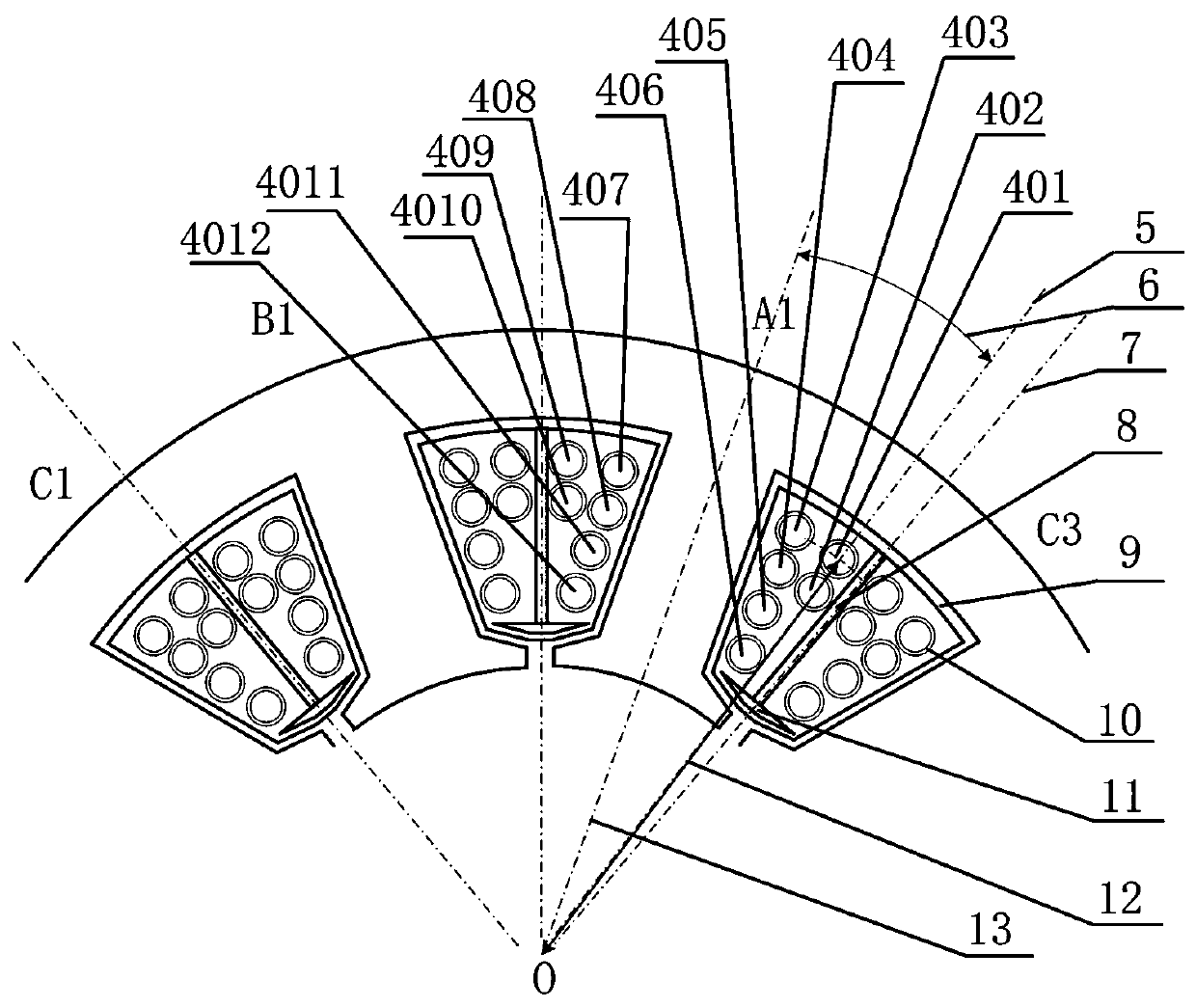

[0025] need for attached figure 2 And attached image 3 It is explained that A1, A2, and A3 belong to phase A of the motor, B1, B2, and B3 belong to phase B of the motor, C1, C2, and C3 belong to phase C of the motor, and O is the center point of the stamping of the motor stator.

[0026] The marked dotted lines are for the convenience of distinguishing the positions of different phases, and at the same time, A1, A2, A3, B1, B2, B3, C1, C2, C3, A, B, and C are only symbols representing different phases; 401—4012 The fact that there are 12 wires in the stator slot in this embodiment is only for the convenience of explaining this embodiment, and does not limit the number of wires in the stator slot in this embodiment.

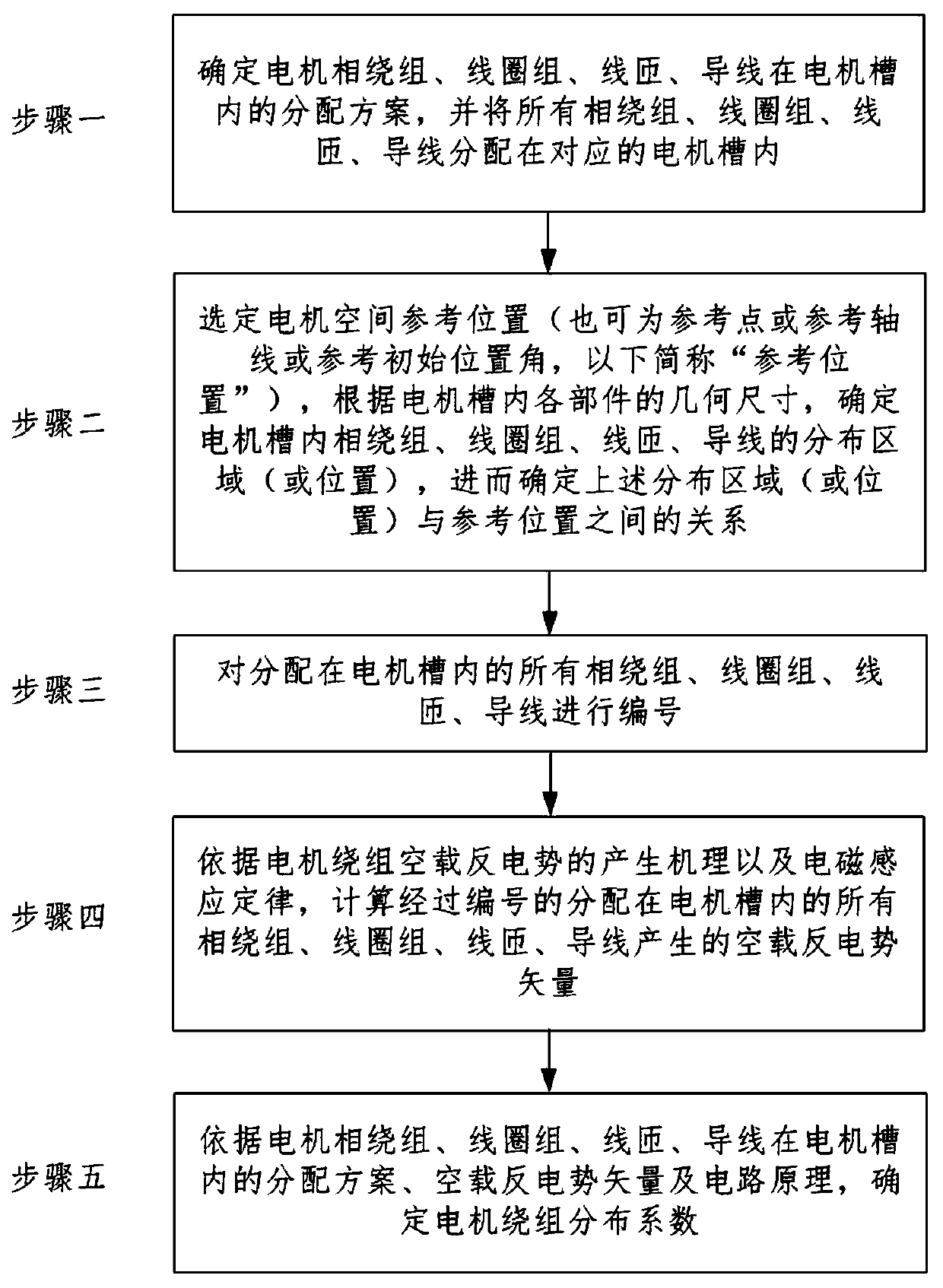

[0027] Such as figure 1 Shown is the implementation steps of the present invention.

[0028] A winding distribution coefficient calculation model and method that considers the difference in the distribution of conductors in the motor slot, which fully conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com