Tamper-evident anti-counterfeit label and manufacturing method thereof

An anti-counterfeiting label and technology for its production method, which is applied in the field of tamper-evident anti-counterfeiting labels and their production, can solve the problems of non-randomness and variability, and achieve the effect of improving the anti-counterfeiting level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

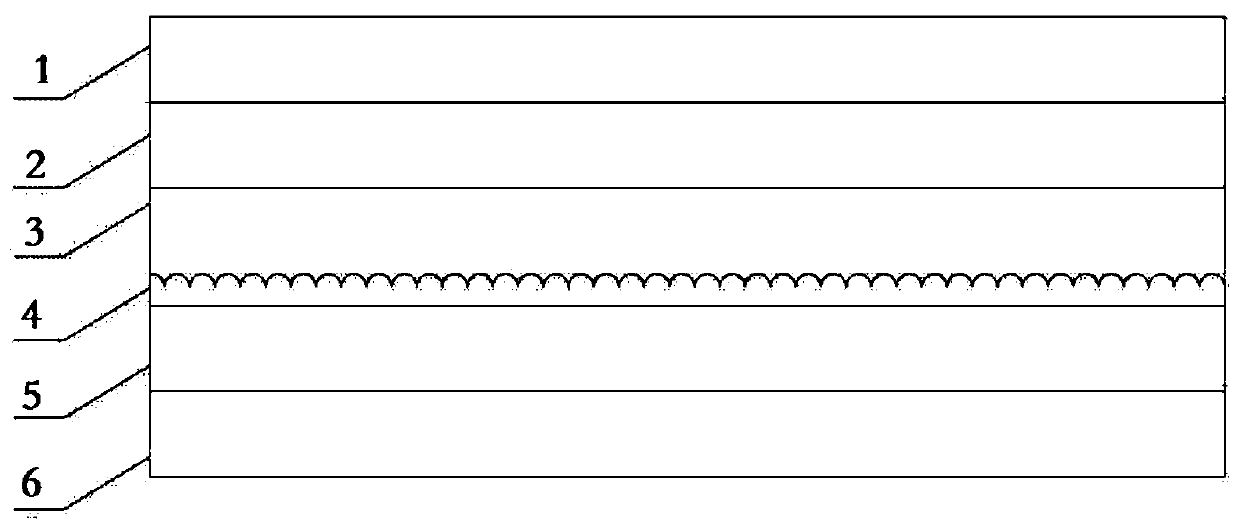

[0023] This embodiment provides a tamper-evident anti-counterfeit label, which includes a first ink layer 1, a release film layer 3, a sequin layer 4, an adhesive layer 5 and a protective layer 6, and each layer is stacked sequentially from top to bottom.

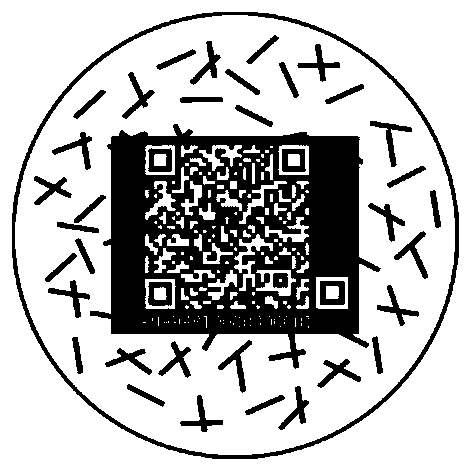

[0024] The first ink layer 1 is a two-dimensional code pattern printed with ink, the two-dimensional code pattern is random, and is printed on the surface of the release film layer 3 by a digital printing machine. In this embodiment, a random two-dimensional code is taken as an example for illustration, and the actual first ink layer 1 may also be a frame, characters, numbers or any combination thereof.

[0025] The release film layer 3 is a transparent and printable film made of PET (polyethylene terephthalate), opp (o-phenylphenol), pe (polyethylene), pp (polypropylene) and the like.

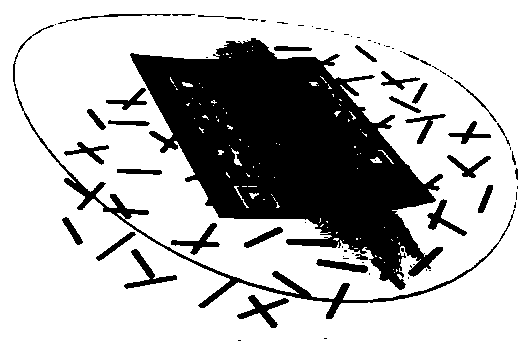

[0026] The sequin layer 4 is composed of several color-changing particles and / or flashing particles, forming random patterns or patterns. ...

Embodiment 2

[0033] This embodiment provides a method for manufacturing an anti-tamper type anti-counterfeit label, corresponding to Embodiment 1, the manufacturing method includes the following steps,

[0034] Step 1, on the protective layer 6, apply glue with a coating machine to form an adhesive layer 5;

[0035] Step 2. Spray or sprinkle powder on the surface of the adhesive layer 5, so that the discoloration particles and / or glitter particles are randomly distributed on the adhesive layer 5 to form the sequin layer 4;

[0036] Step 3, enter the oven to dry the glue, so that the sequin layer 4 and the adhesive layer 5 are firmly combined;

[0037] Step 4, the release film layer 3 and the sequin layer 4 are pressed together by a roller pressing device;

[0038] Step 5, printing a randomly generated two-dimensional code on the surface of the release film layer 3 to form the first ink layer 1 .

[0039] Preferably, the color-changing particles and / or glitter particles described in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com