Slave cylinder with height-adjustable piston and clutch with slave cylinder

A clutch and piston technology, applied in the field of slave cylinders, can solve problems such as assembly difficulties, and achieve the effect of simple method and simplified position setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

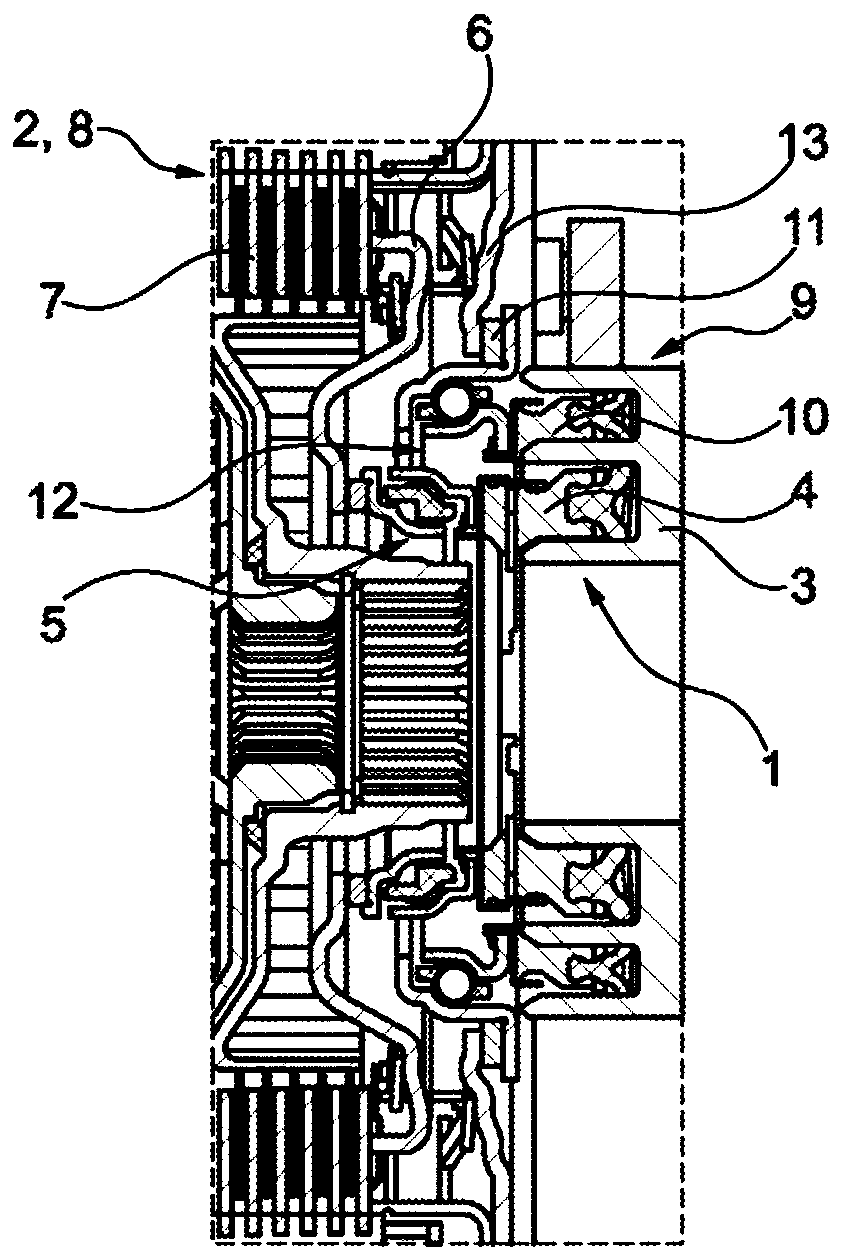

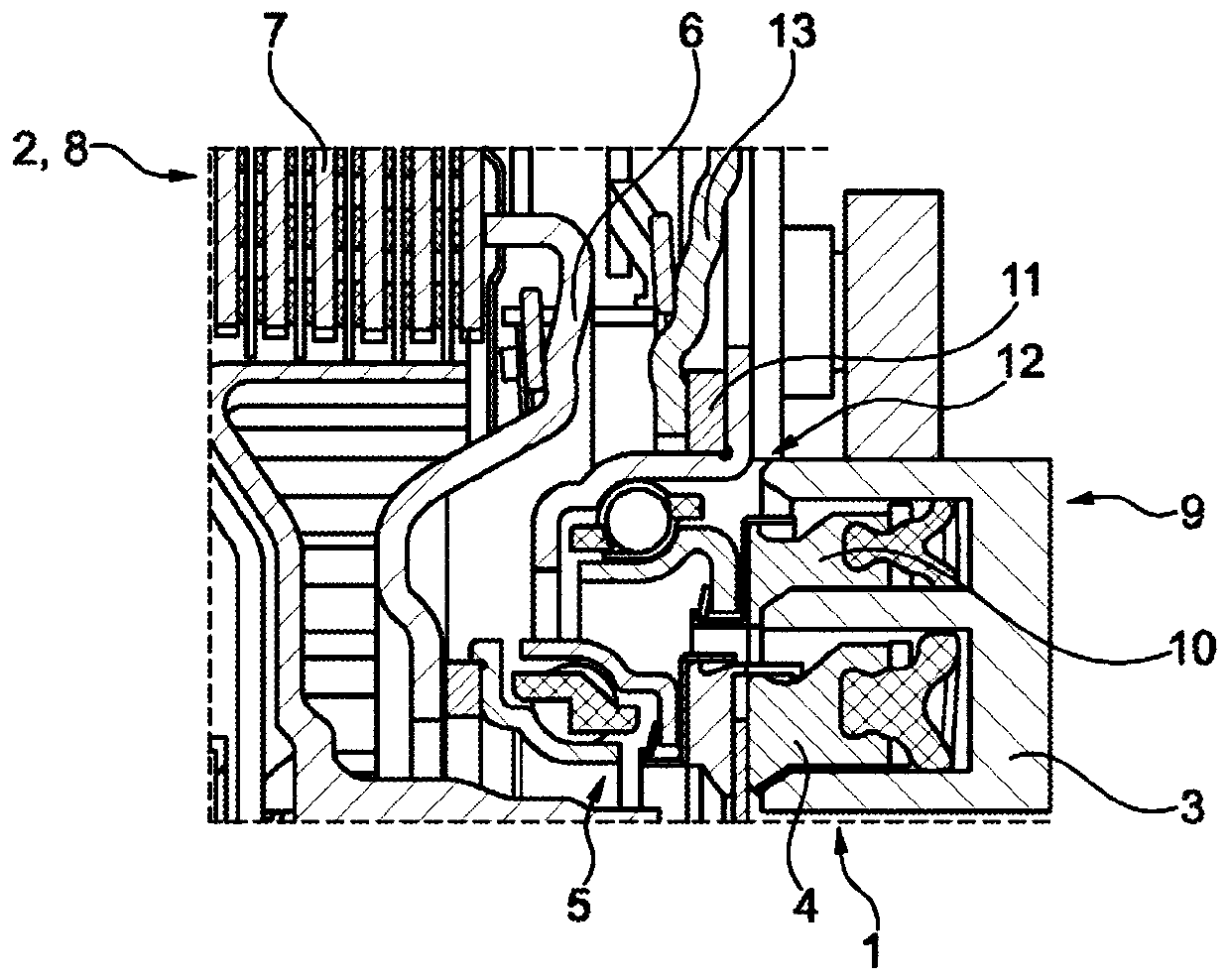

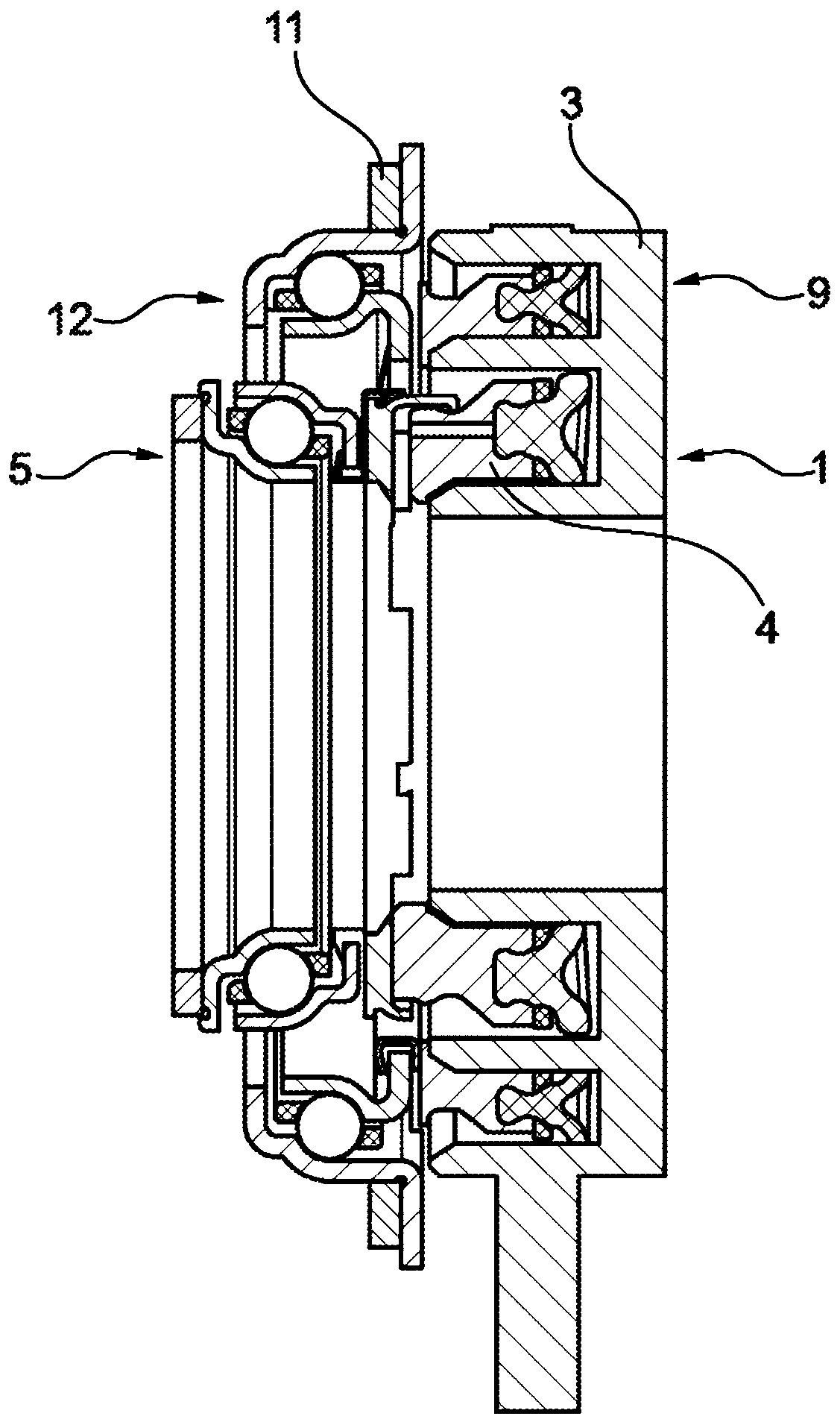

[0035] Figures 1 to 3 A slave cylinder 1 for actuating a clutch 2 of a motor vehicle is shown. The slave cylinder 1 has a housing 3 in which a piston 4 is arranged axially displaceable. When the piston 4 moves axially relative to the housing 3, the actuating bearing 5 for actuating the clutch 2 is displaced. The piston 4 is designed structurally and / or materially in such a way that it can occupy different predetermined axial lengths.

[0036] When the steering bearing 5 is disengaged, the pressure pot 6 is displaced in the axial direction, so that the clutch discs 7 of the clutch 2 as a friction clutch 8 are pressed together, thereby transmitting torque in a non-positive manner. In the illustrated embodiment, there is a second slave cylinder 9 which is arranged concentrically with the slave cylinder 1 according to the invention. The second slave cylinder 9 is designed as a conventional slave cylinder, the piston 10 of which is not adjustable in height. In order to be able...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com