Tapered wedge device for floating material pressing

A wedge and stop technology, applied in the field of floating pressing wedge device, can solve the problems of inability to press material vertically, inconvenient to assemble, and the roller bracket has no anti-over-rotation design, so as to save mold space and cost, reduce processing Assembly difficulty and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

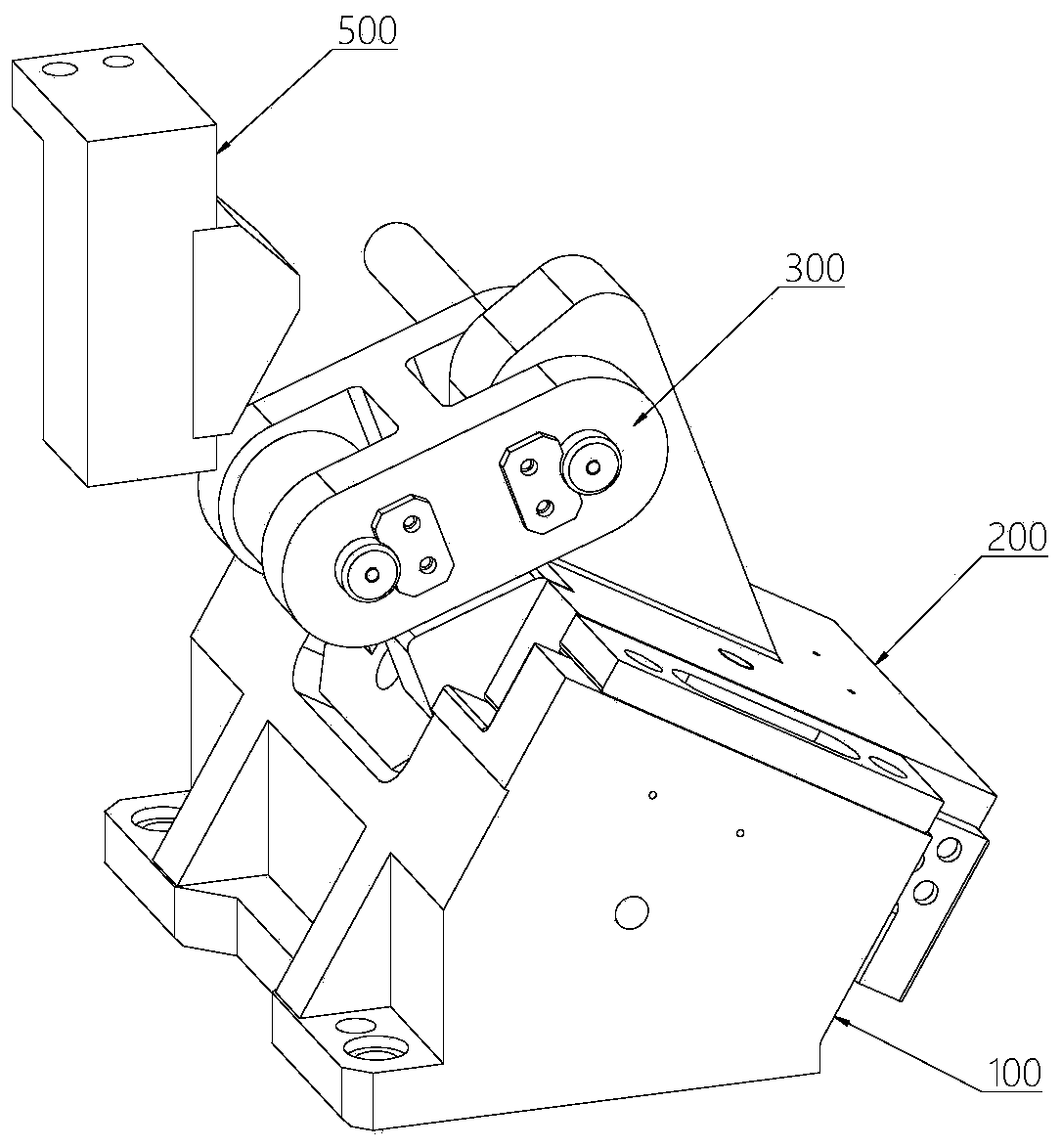

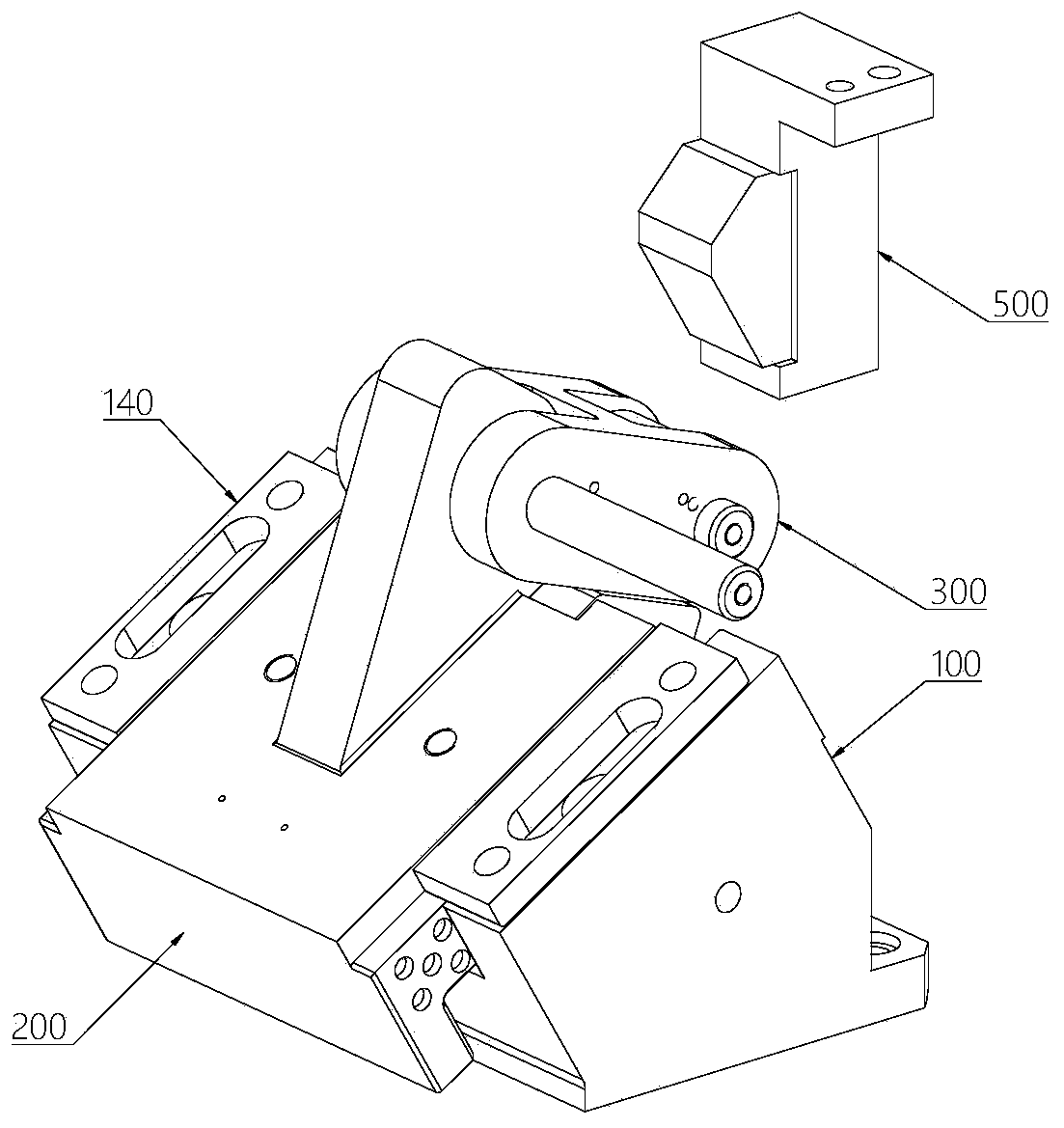

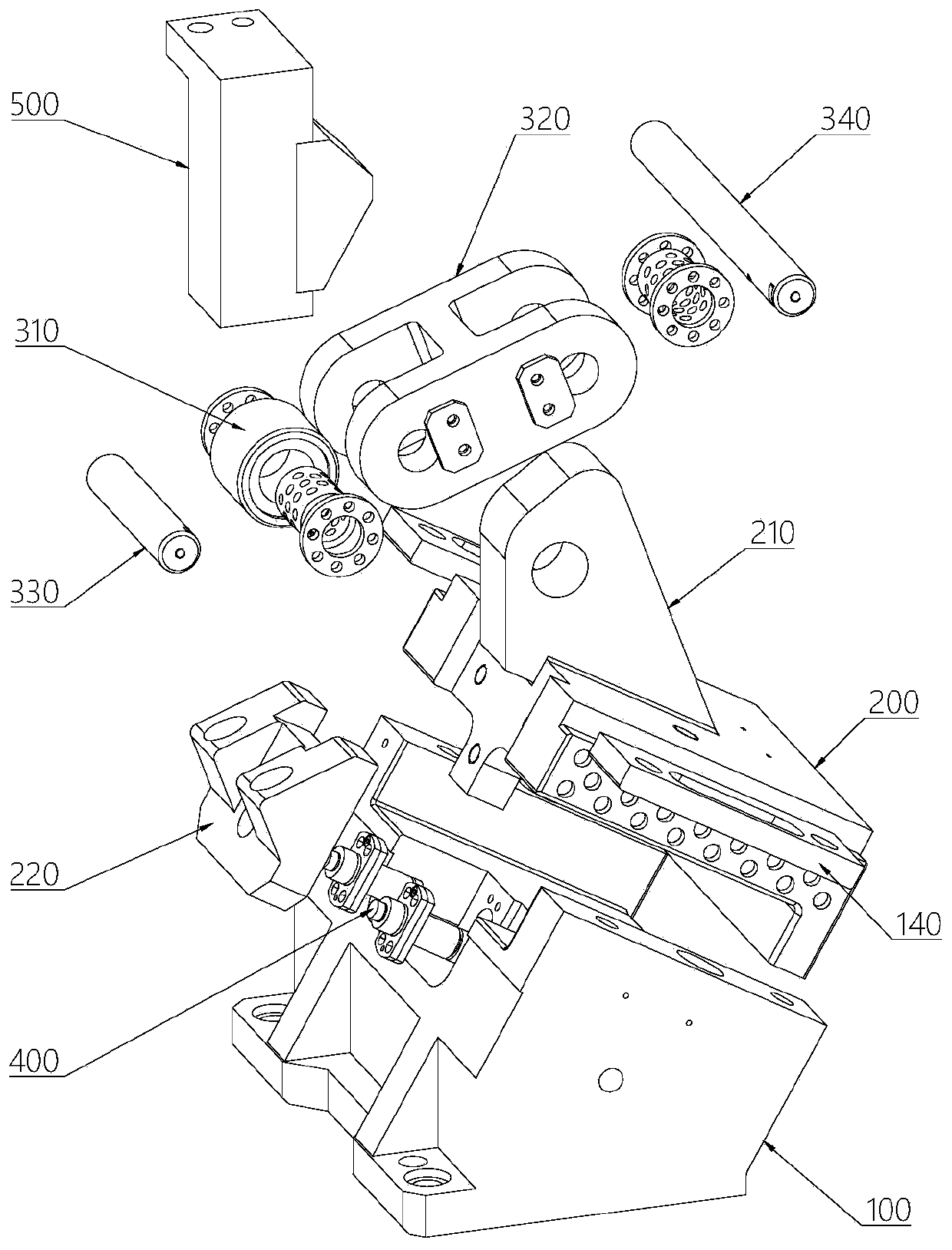

[0024] Such as Figure 1-8 As shown, the floating pressing wedge device designed in the present invention includes a base 100 , a slider 200 , a rotary pressing block 300 , a slider reset part 400 , a slider limiting structure, and an optional driving device 500 . in:

[0025] The upper part of the base 100 is provided with a chute 130 , the slider 200 is installed in the chute 130 , and forms a guide rail pair with the base 100 that slides obliquely (relative to the base installation plane). Pressing plates 140 for preventing the slider 200 from detaching from above the chute 130 are respectively provided on the upper parts of both sides of the chute 130 . The driving end of the chute 130 excavates a movable slot 110 of a certain depth below the sliding surface 150 of the base at the bottom thereof, and two nitrogen spring installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com