Cutting blade and cutting device using same

A blade and cutting part technology, applied in the field of cutting devices, can solve the problem of difficulty in forming high-precision blade blades, and achieve the effect of improving cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the cutting device 1 and the blade 10 according to preferred embodiments of the present invention will be described in detail with reference to the drawings.

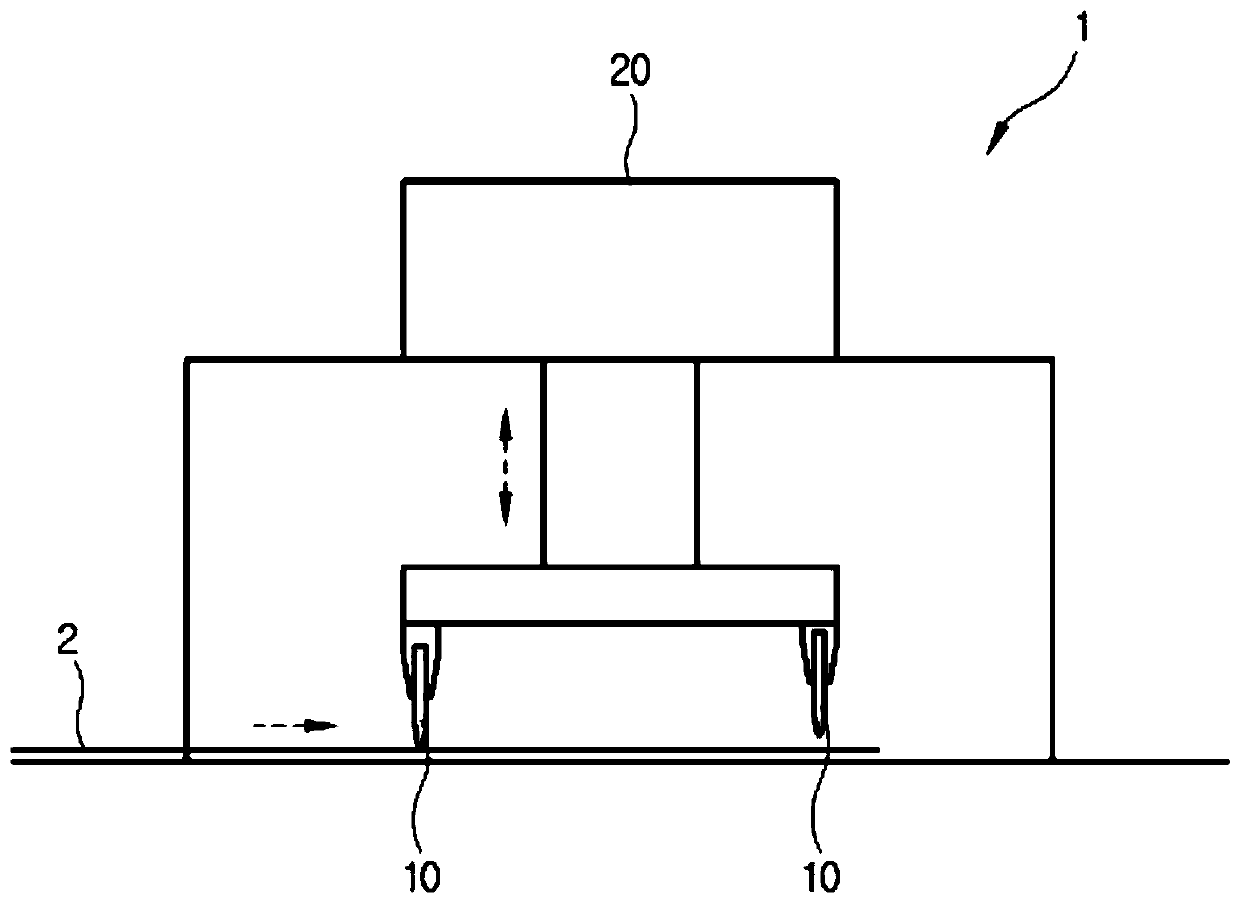

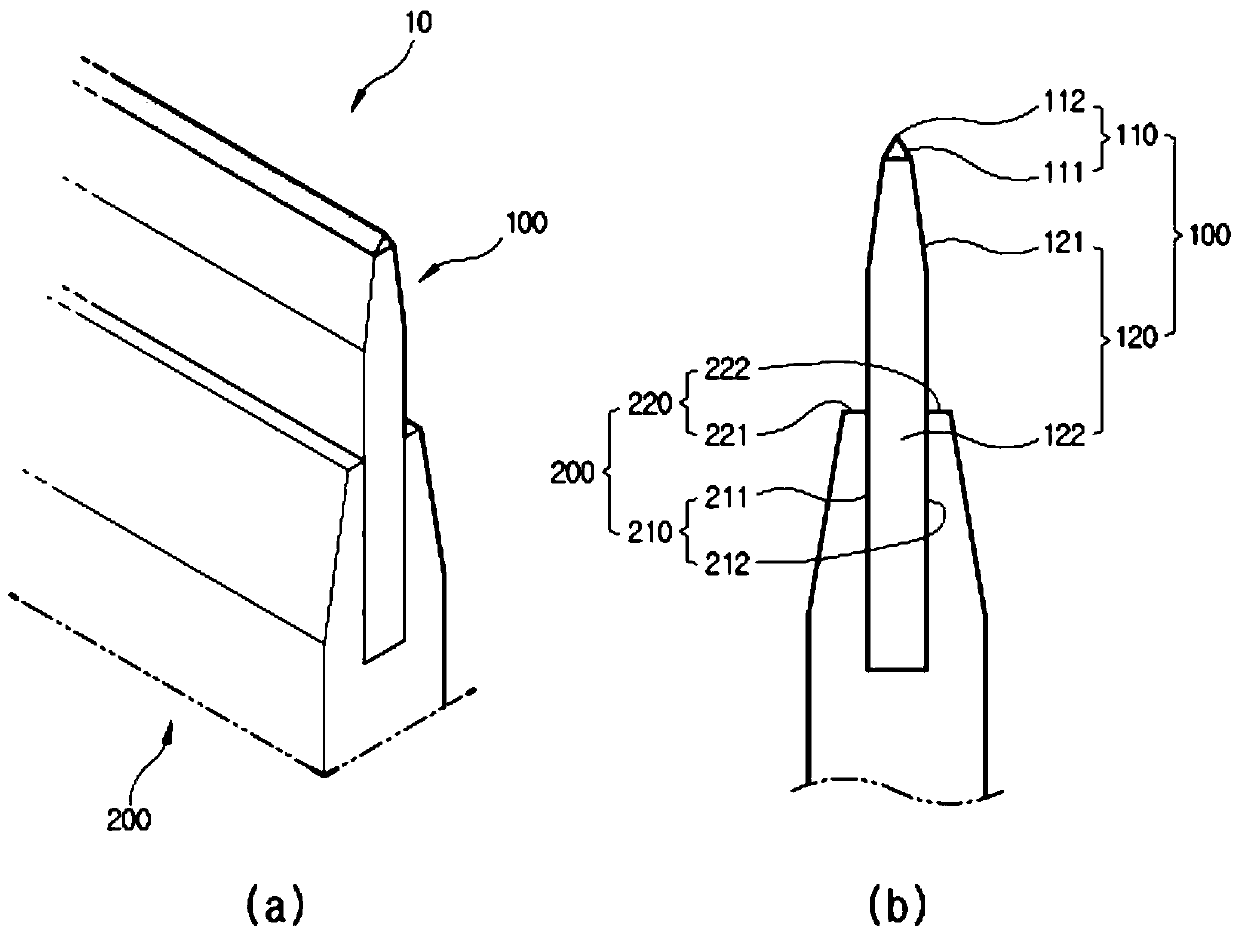

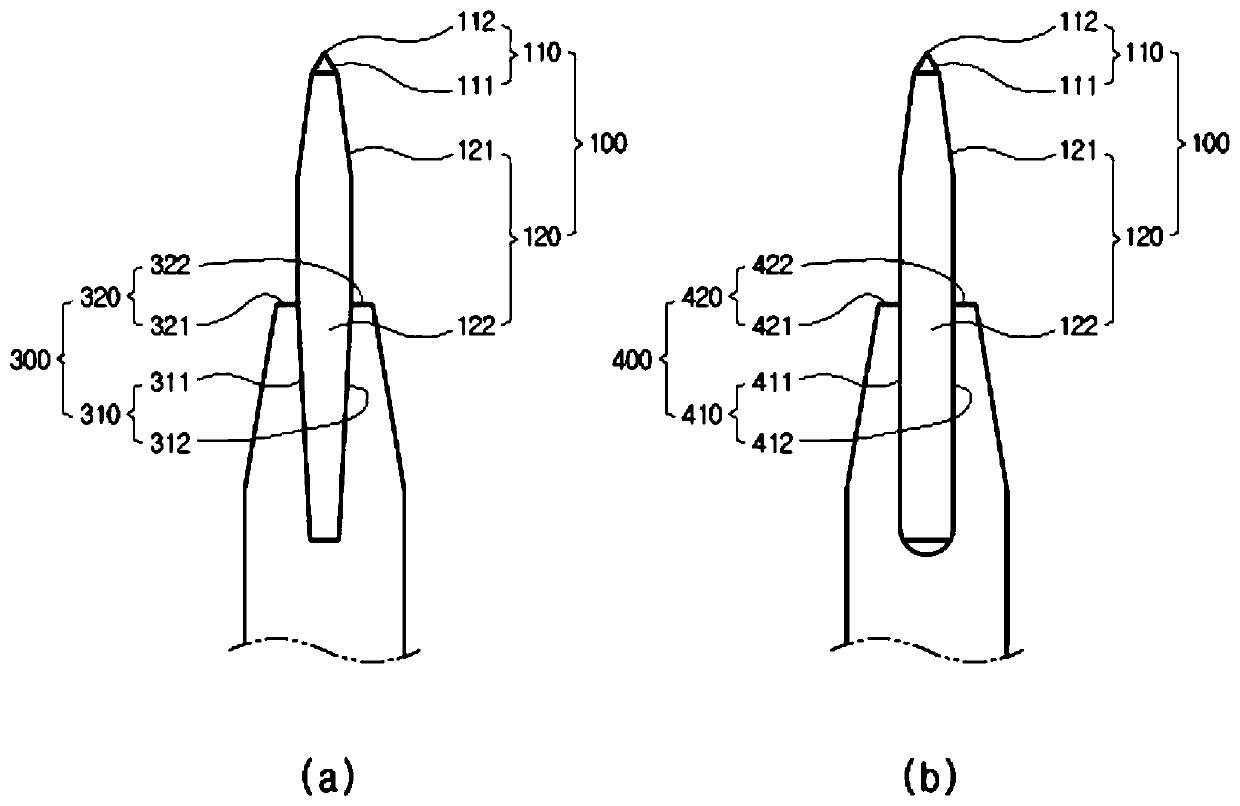

[0031] figure 1 is a schematic illustration of a cutting device 1 according to the present invention, figure 2 are detailed drawings (a), (b) of the blade 10, image 3 is a deformation example diagram of the blade 10, Figure 4 is a manufacturing process diagram of the blade 10.

[0032] The cutting device 1 includes a blade 10 and a blade driving unit 20 . The blade driving part 20 includes: a blade clamping part (not shown), which clamps the blade 10; an up and down moving shaft (not shown), which is connected with the blade clamping part; an up and down moving motor (not shown), which Rotating the vertical movement shaft causes the blade clamping portion to move up and down. In order to manufacture a semiconductor component 2 including an MLCC (Multilayer Ceramic Capacitor) 2 , the blade dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap