Environment-friendly building material and preparation method of nano-pore aqueous solution additive of environment-friendly building material

A nanoporous, aqueous solution technology, applied in the direction of coating, etc., can solve the problem of narrow application range, and achieve the effects of improving immunity, adjusting autonomic nerves, and purifying blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method for a nanoporous aqueous solution additive, comprising the steps of:

[0027] Step 1, using water as a carrier to become water vapor when boiling;

[0028] Step 2, let the water vapor pass through the nanoporous material with a pore size smaller than 50 nanometers, and let the small water molecules of the water vapor surround the particles produced by the nanoporous material at a preset temperature. The nanoporous material includes: SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 , FeO, B 2 o 3 and rare earth and with three-dimensional granular zeolite composition, the SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 , FeO, B 2 o 3 The weight ratio of the rare earth to the three-dimensional granular zeolite is: 0.43-0.48: 0.08-0.12: 0.06-0.10: 0.04-0.08: 0.04-0.08: 0.04-0.08: 0.08-0.12: 0.06-0.10;

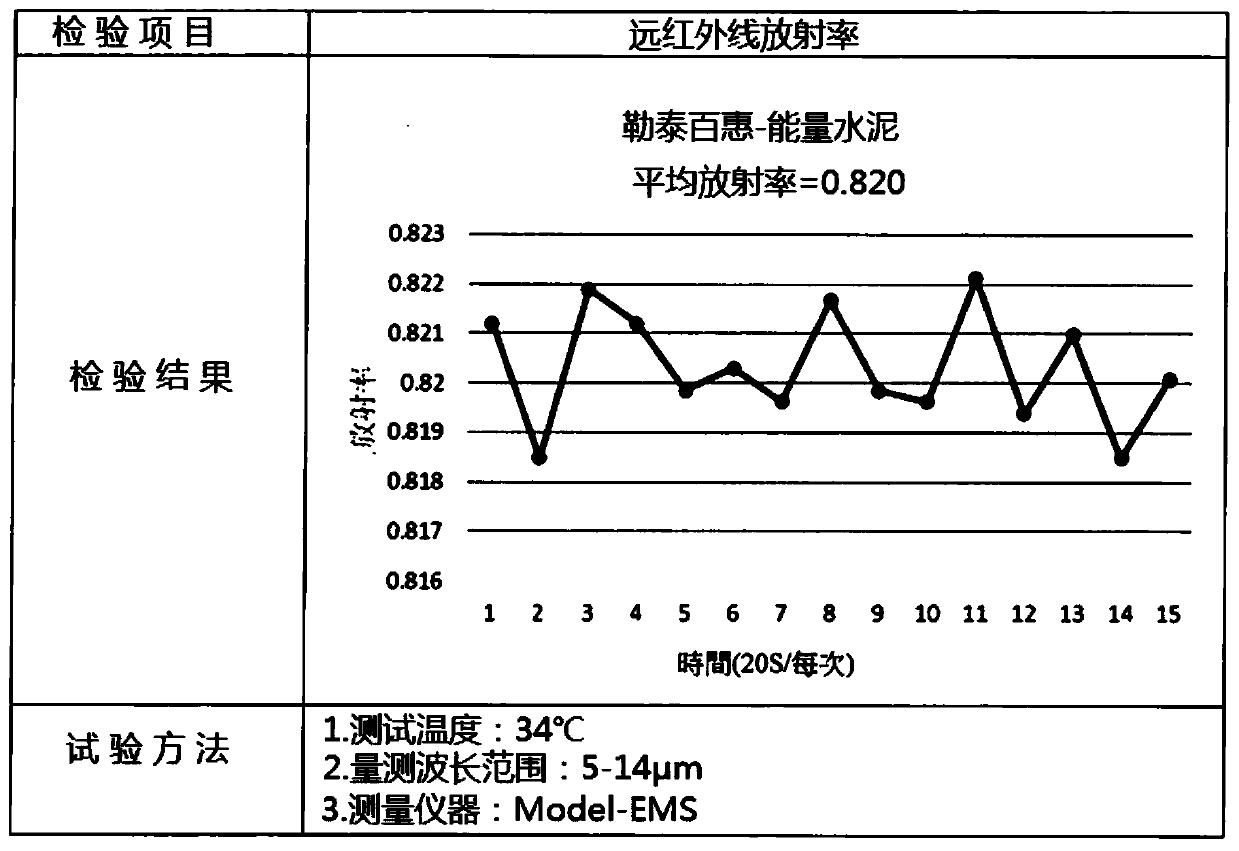

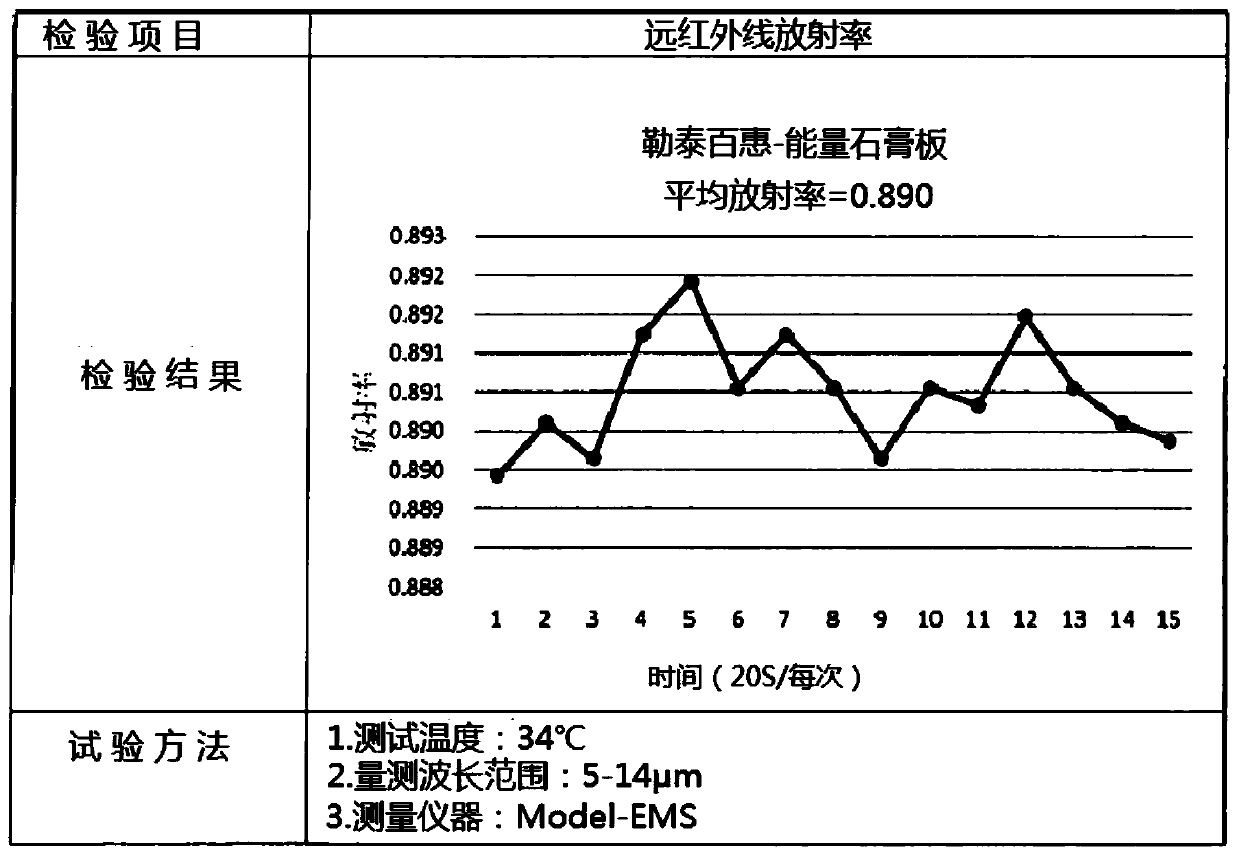

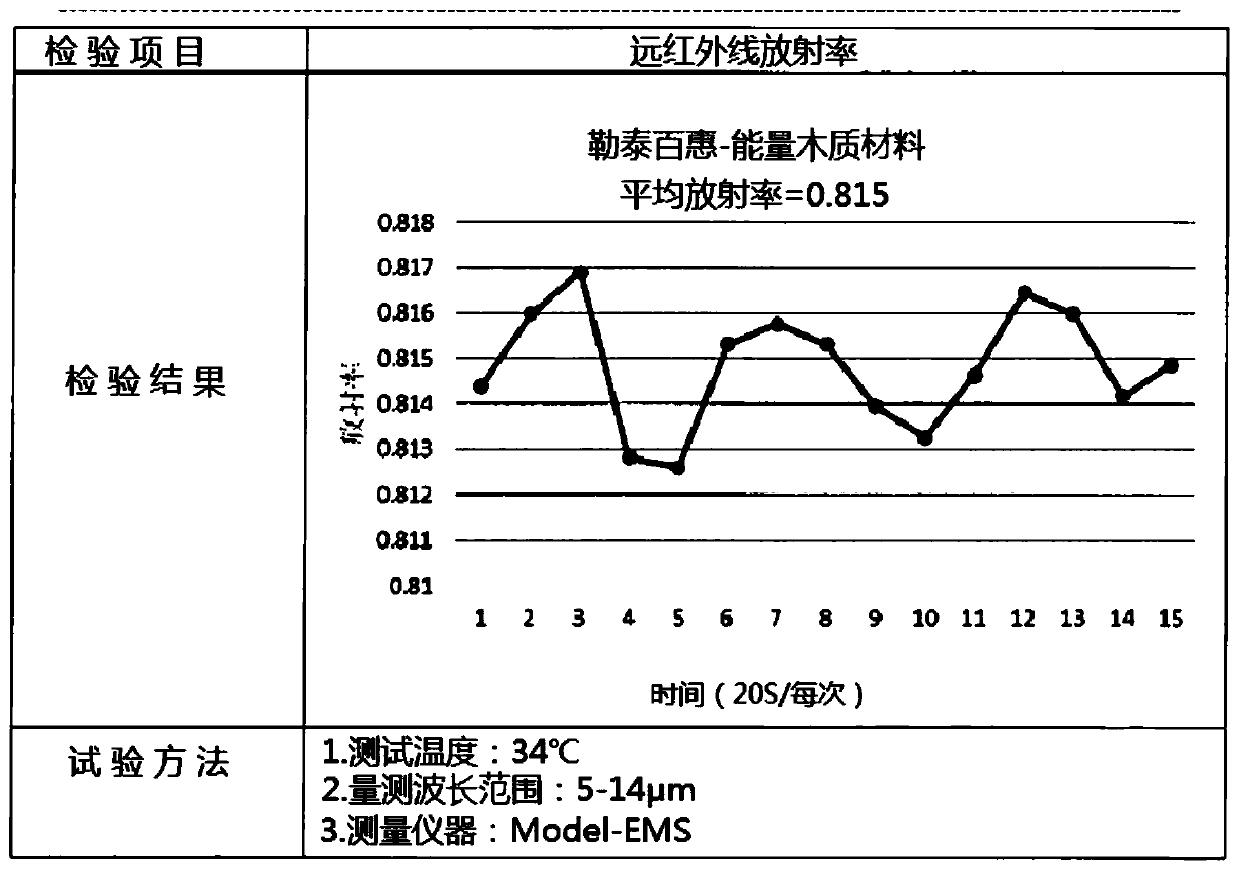

[0029] Step 3, the aqueous solution obtained after being condensed by the condenser is the nanoporous aqueous solution additive capable of releasing far infrared rays...

specific Embodiment 1

[0031] A preparation method of nanoporous aqueous solution additive, is characterized in that, comprises the steps:

[0032] Step 1, using water as a carrier to become water vapor when boiling;

[0033] Step 2, let the water vapor pass through the nanoporous material with a pore size smaller than 50 nanometers, and let the small water molecules of the water vapor surround the particles produced by the nanoporous material at a preset temperature. The nanoporous material includes: SiO2, TiO2, The composition of Al2O3, Fe2O3, FeO, B2O3 and rare earth and three-dimensional granular zeolite, the weight ratio of SiO2, TiO2, Al2O3, Fe2O3, FeO, B2O3 and rare earth to three-dimensional granular zeolite is: 0.46:0.10:0.08:0.06: 0.06:0.06:0.10:0.08;

[0034] Step 3, the aqueous solution obtained after being condensed by the condenser is the nanoporous aqueous solution additive capable of releasing far infrared rays and negative ions.

[0035] The nanoporous aqueous solution additive of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com