Method for industrially producing bromo-pyrazolidinic acid through micro-channel

A technology of bromopyrazolidinic acid and microchannel, which is applied in the field of microchannel industrial production of bromopyrazolidinic acid, can solve the problems of low yield and purity, cumbersome post-processing, long reaction time, etc., and achieve simple post-processing , shorten the reaction time, the effect of short reaction time

Pending Publication Date: 2020-07-24

山东华科化工有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a kind of microchannel industrial production method of bromopyrazolidinic acid on the basis of prior art, take 2-halogenated heterocyclic compound as raw material, carry out hydrazinolysis in microchannel reactor , ring cl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

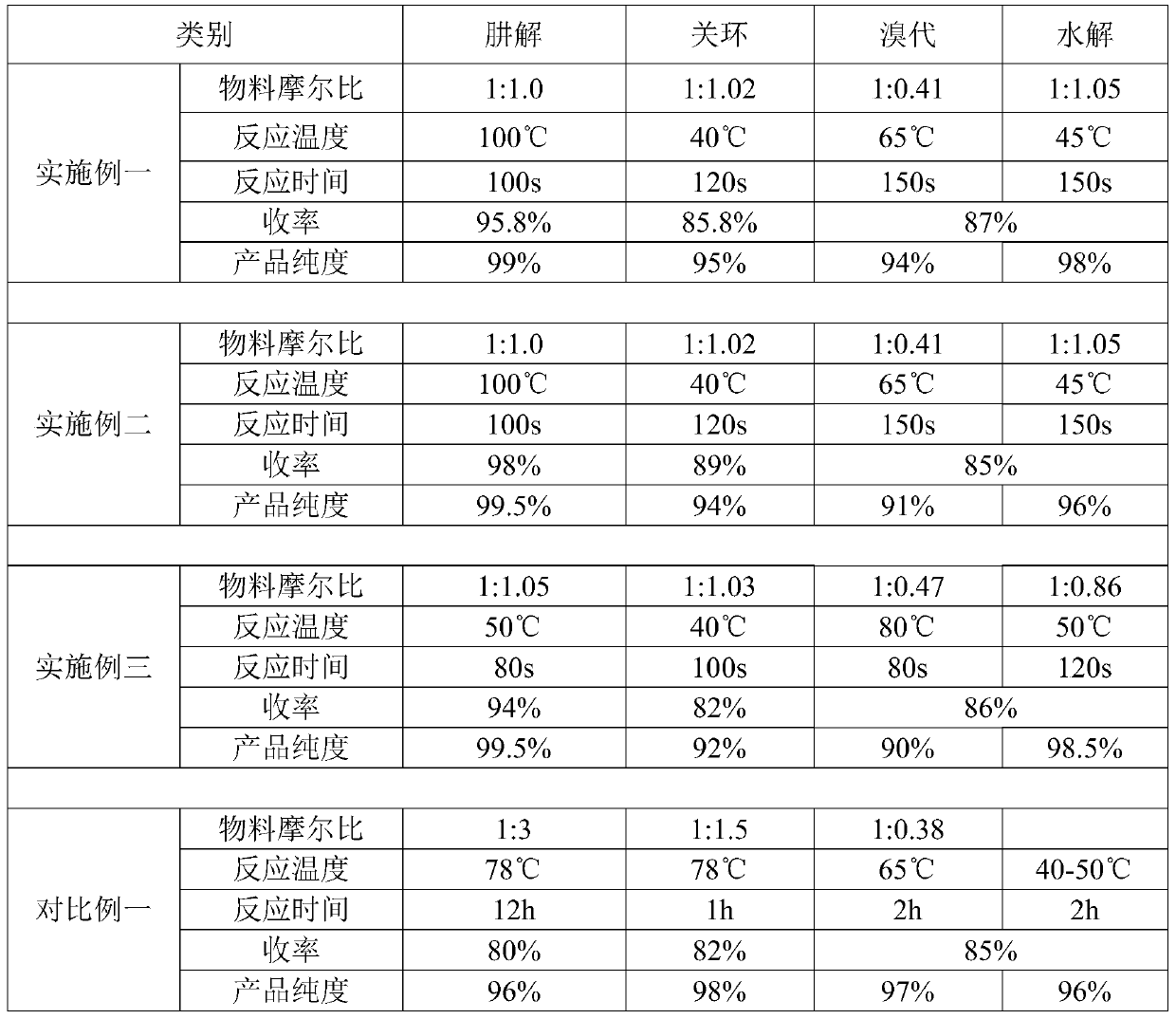

The invention relates to a method for industrially producing bromo-pyrazolidinic acid through a micro-channel. The method comprises the following steps: taking a 2-halogenated heterocyclic compound asa raw material; carrying out hydrazinolysis, cyclization, bromination and hydrolysis reactions in a micro-channel reactor; and carrying out acidification and filtration to obtain bromo-pyrazolidinicacid with high yield and high purity. The reaction time is greatly shortened, the safety is high, the pollution is small, pollutant emission is little, the cost is low, the post-treatment is simple, the yield of an intermediate product in each step is 80% or above, the purity of the intermediate product in each step is 90% or above, the purity of a final product is 95% or above, and the method isparticularly suitable for industrial large-scale production.

Description

technical field [0001] The invention belongs to the technical field of organic synthesis, and in particular relates to a method for the industrial production of bromopyrazolinic acid through a microchannel. Background technique [0002] Bromopyrazolidinic acid compounds are important intermediates of pesticides. Pyrazole pesticides, especially chlorantraniliprole and its derivatives, have a very significant effect on mammalian and pest ryanodine receptors. The difference in selectivity greatly improves the safety of mammals and other vertebrates. It has the characteristics of high efficiency, broad spectrum, good persistence, low toxicity, and environmental friendliness. Its production process has become a hot research topic at home and abroad. At present, the production methods of bromopyrazolidine acid compounds reported in domestic and foreign literature are generally only suitable for laboratory preparation due to long reaction time, safety, low yield, high cost and comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D401/04B01J19/00

CPCC07D401/04B01J19/0093

Inventor 周红霞程李中罗志峰左俊坤刘强陈国云倪忠强

Owner 山东华科化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com