A kind of washable ink resistant to high temperature and high pressure bonding and its preparation method

A technology of high temperature resistance and ink, applied in the direction of ink, household appliances, applications, etc., can solve the problems of coating cracking, not easy to wash, and not solve the flexibility requirements of flexible boards, and achieve the effect of solving cracking and excellent flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of carboxyl-containing acrylic acid copolymer resin:

[0038] Mix according to the ratio of methacrylic acid, methyl methacrylate, cyclohexyl methacrylate and dibutyl itaconate, stir evenly, add 1% reaction catalyst organic peroxide, stir evenly, control methacrylic acid, formazan The weight ratio of methyl acrylate, cyclohexyl methacrylate and dibutyl itaconate is 4:1-3:1-3:3-4, prepare a certain amount of organic solvent in the reaction kettle as the reaction substrate , at 90-120 degrees Celsius, add the prepared reactant mixture dropwise while stirring, until all are added and completely reacted. Adjust the reaction temperature and stirring speed, and adjust the ratio of the four raw materials to obtain the carboxyl acrylic acid copolymer resins A, B, C, and D with an acid value of 80-200KOH / g and a weight-average molecular weight of 1000-5000 respectively. The ratio range of the raw materials is expanded so that the weight ratio of me...

Embodiment 2

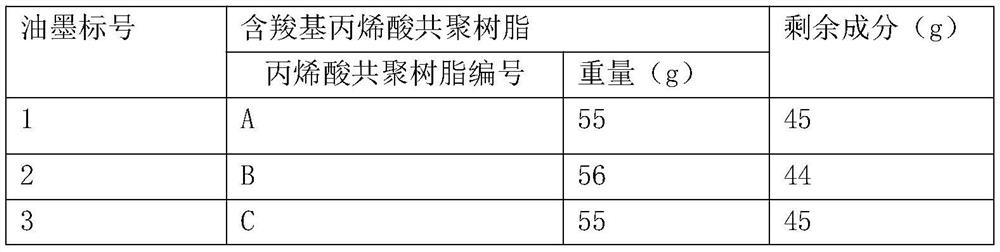

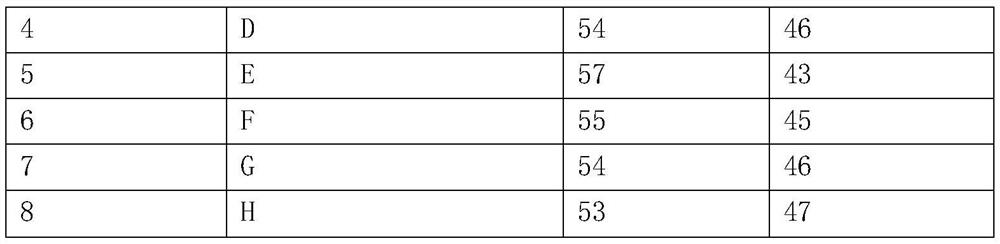

[0042] Example 2: Preparation of high-temperature and high-pressure lamination washable ink:

[0043] Select different carboxyl-containing acrylic acid copolymer resins in embodiment 1 respectively, and 3g photoinitiator (purchased from the TPO of Beijing Yingli Science and Technology), 1g pigment (Mitsubishi Corporation MA-100 carbon black), 1g dispersant (German BYK chemical The company's BYK-204), 20g inorganic filler (barium sulfate of Sahariben Chemical Co., Ltd., Germany), 1g defoamer (organic silicon defoamer KS-66 of Japan Shin-Etsu Chemical Co., Ltd.), 1g leveling agent (Germany BYK Chemical company's BYK-354) and 15g of organic solvent (dipropylene glycol methyl ether DPM of Jiangsu Yida Chemical Co., Ltd.) were mixed with a disperser (U400\80-220 high-speed disperser) for 30 minutes at high speed, and then three Roller grinder (S-65 three-roller grinder) grinds, and obtains the printing ink that particle size is less than 5 microns; Other compositions except carboxy...

Embodiment 3

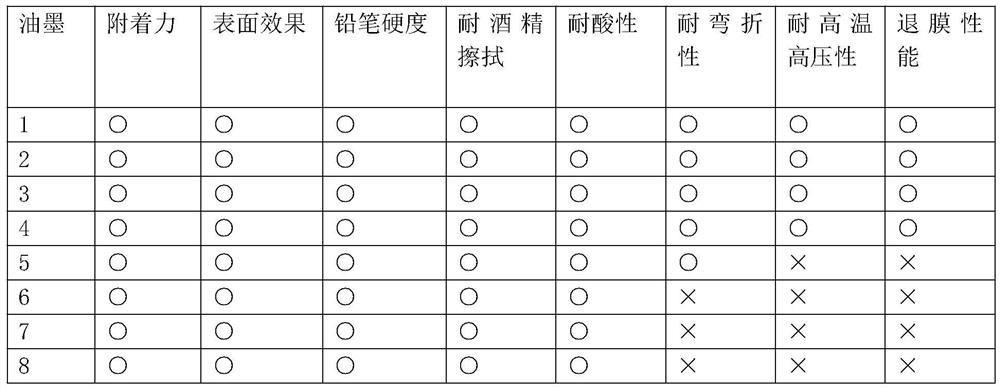

[0047] Embodiment 3: the performance test of the coating film prepared by printing ink

[0048] The high temperature and high pressure lamination washable ink 1-8 prepared in Example 2 was prepared as a standard coating film, and the following properties of the coating film were evaluated.

[0049] 1. Adhesion

[0050] Print the ink 1-8 of Example 2 on the clean and dry substrate by screen printing method, put it into a hot air circulation drying oven at 130°C and dry it for 60 minutes, and then test it by cross-cut tape method Adhesion. Adhesion was evaluated according to the following criteria.

[0051] ○: No peeling off at all;

[0052] X: The edge of the ruled line came off.

[0053] 2. Surface effect

[0054] The test specimen prepared in the same manner as 1. above was observed visually. Surface effects were evaluated according to the following criteria.

[0055] ○: The surface is smooth and wrinkle-free;

[0056] X: The surface is uneven or wrinkled.

[0057] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com