Argon station scrap steel adding system and scrap steel adding method

An argon station and scrap steel technology, which is applied in the field of converter argon station, can solve the problems of limited amount of scrap added to saturation and limited converter capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

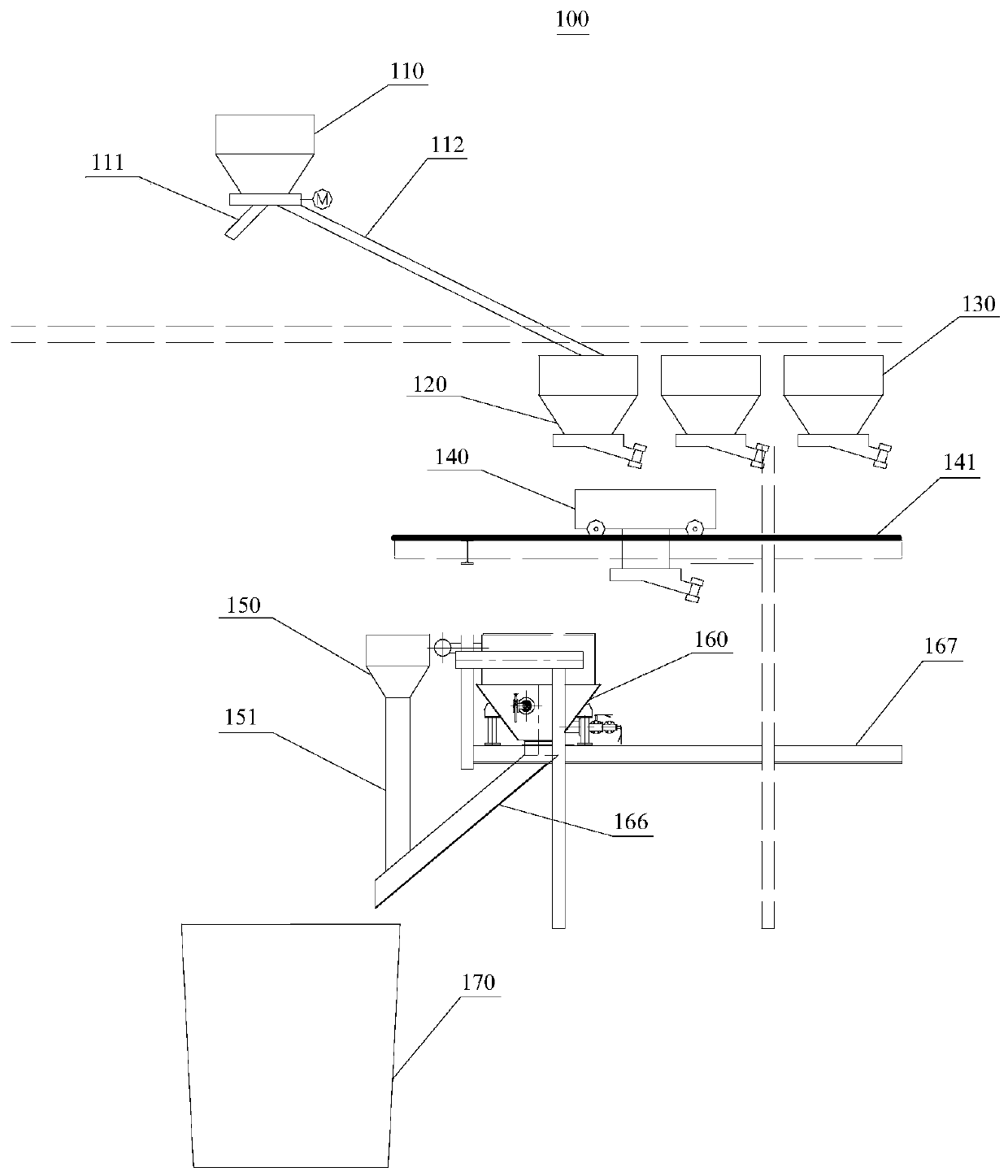

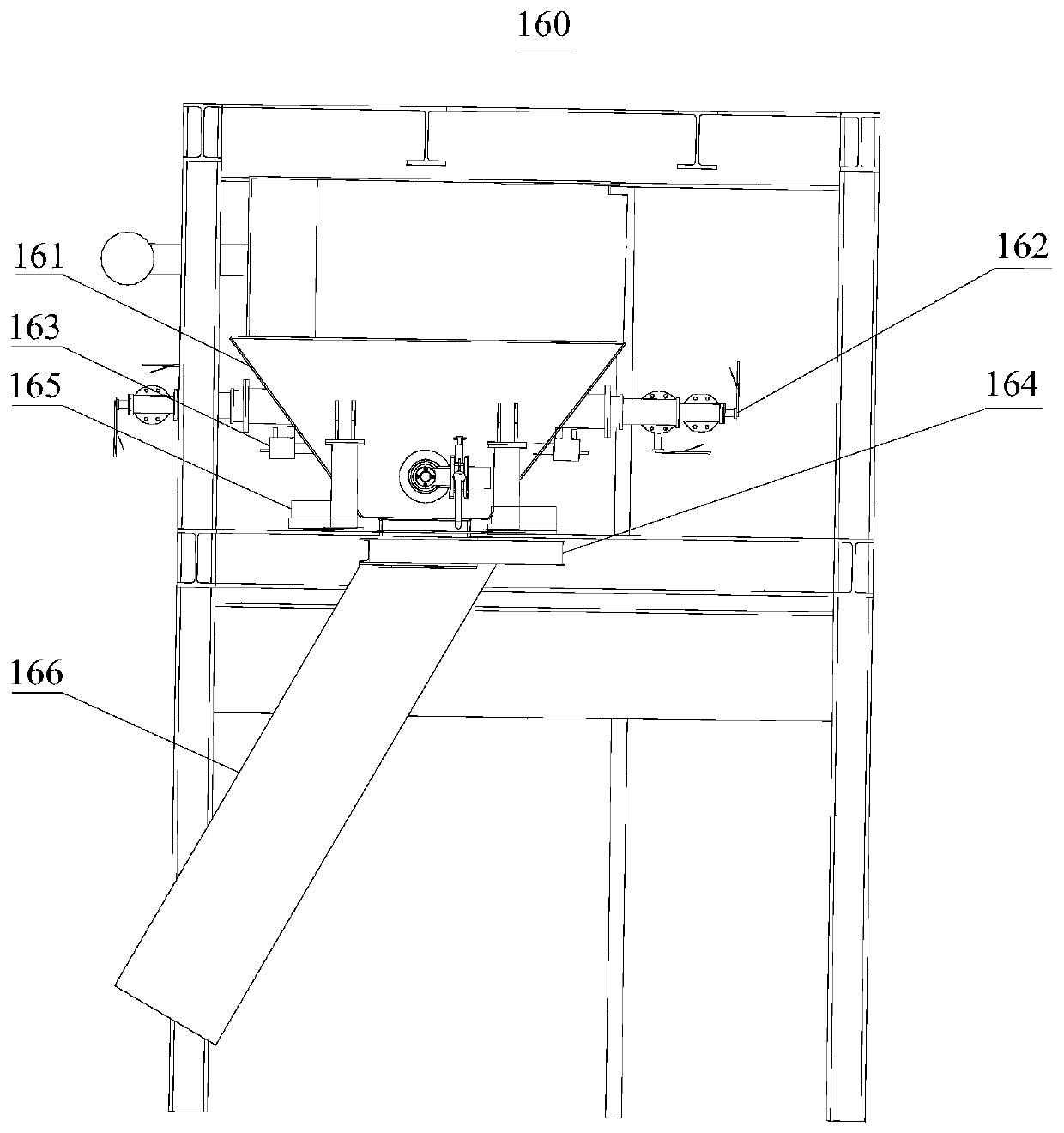

[0053] Please see figure 1 , an argon station scrap steel adding system 100 provided in this embodiment is used to add scrap steel into the ladle 170 of the argon station. The argon station scrap steel adding system 100 includes layered arrangement from top to bottom: distributor 110, Scrap steel silo 120 and alloy silo 130, weighing receiving trolley 140, baking device 160, alloy lowering silo 150, and steel ladle 170 are located at the bottom. The device structure and function of each layer will be introduced in detail below.

[0054] The first layer: distributor 110

[0055] The feeder 110 is used to accommodate steel scrap and provide scrap, and the feeder 110 can be obtained by utilizing an existing auxiliary raw material feeding system for a converter. In the embodiment of this application, the distributor 110 can supply materials to the converter and the argon station at the same time, and the outlet of the distributor 110 is provided with a two-way (with two outlets)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com