Raw material preheating and shoot charging system of top-blown oxygen steelmaking converter

A steel-making converter and oxygen top-blowing technology, applied in the manufacture of converters, etc., can solve problems such as inability to maintain parabolic trajectory, uneven air flow offset, system equipment verification, etc., to speed up melting and chemical reaction speed, reduce manufacturing cost, The effect of manufacturing process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

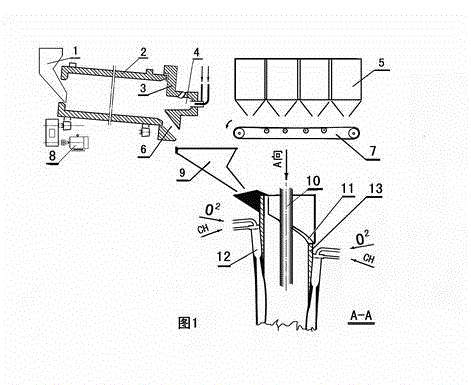

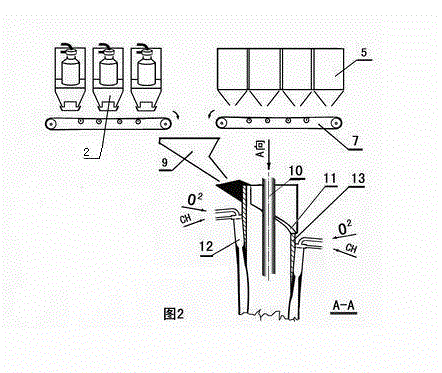

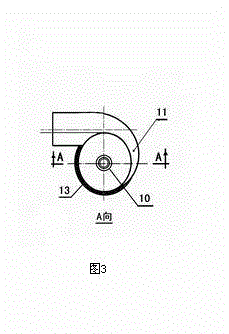

[0030] As shown in the figure, a raw material preheating shooting feeding system for an oxygen top-blown steelmaking converter is composed of a raw material bin 5, a raw material heating furnace 2, and a weighing hopper 9. A feeding conveyor belt 7 is arranged below the raw material bin 5. The small flue 13 of the hood of the oxygen top-blown steelmaking converter is provided with a spiral batching ramp 11 with a chute. The tangent lines of the channel 13 are parallel or coincident. On the pipe wall of the small flue at the lower part of the feeding port, a plurality of gas injection pipes with rocket motors are installed. A rocket engine is installed in each gas injection pipe, and the gas injection pipes are inclined downward. To blow into the small flue 13, the rocket engine and high pressure O 2 Connect to high pressure CH fuel source. Described rocket engine is made up of combustion device 23, combustion chamber 12 and Lafal nozzle 24, high pressure O 2 It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com