Turnout rapid construction apparatus and method during existing station transformation

A technology for existing stations and construction devices, applied to roads, tracks, laying tracks, etc., can solve the problems of difficult pre-paved sites for turnouts, short key points, and limited boundaries, so as to reduce maintenance workload, speed up conversion progress, and realize mechanized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

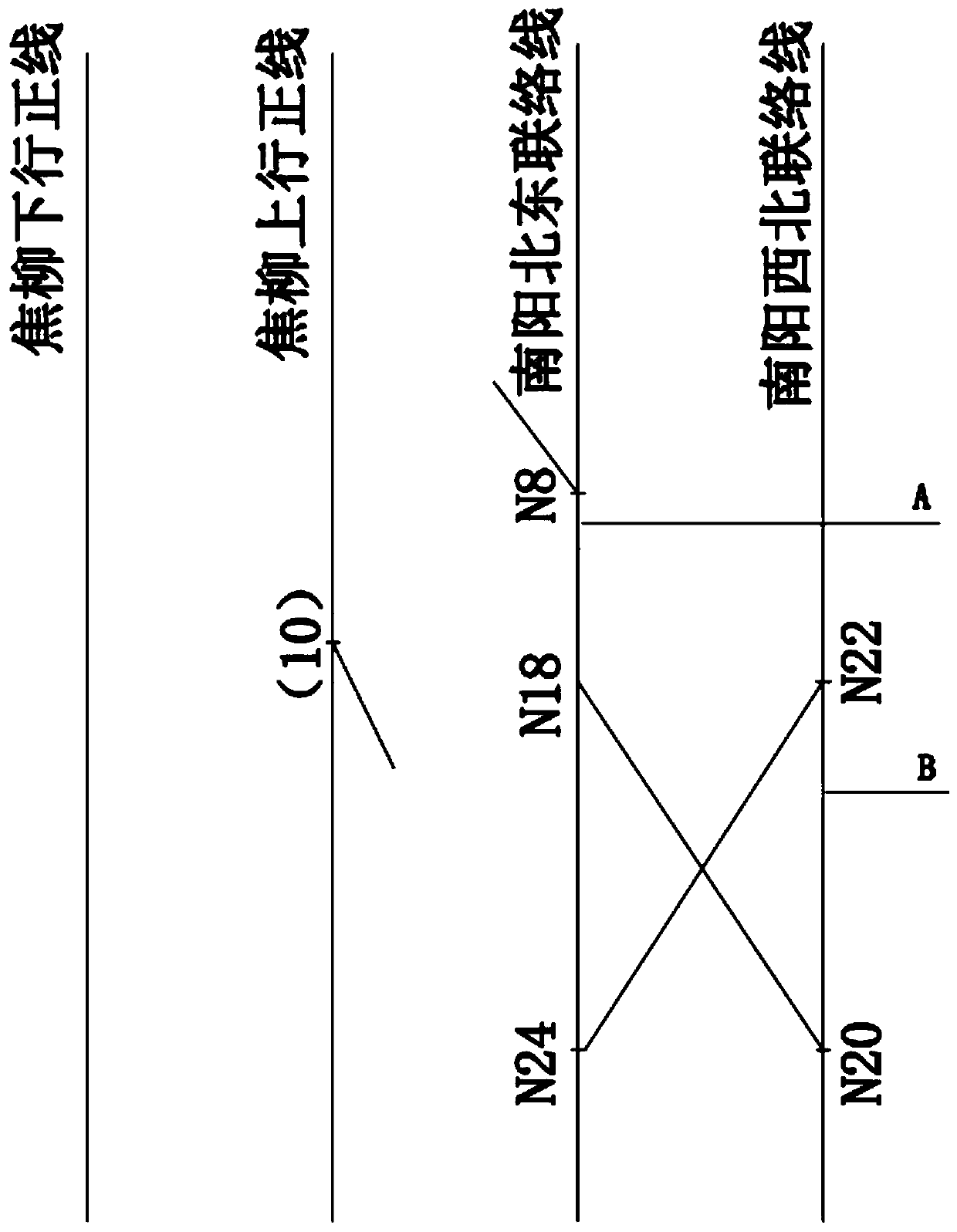

[0063] In this embodiment, the reconstruction of a group of turnouts in the south throat area of the railway station in Nanyang City, Henan Province is taken as an example. Figure 1-29 As shown in the figure, "N" represents a new turnout, and "(10)" represents an existing turnout; in this embodiment, it is mainly the construction method of No. N8 turnout; N6, N10, N12, N18, N20, N22, and N24 are all A new turnout was laid for the station renovation, and the construction time was earlier than the N8 turnout.

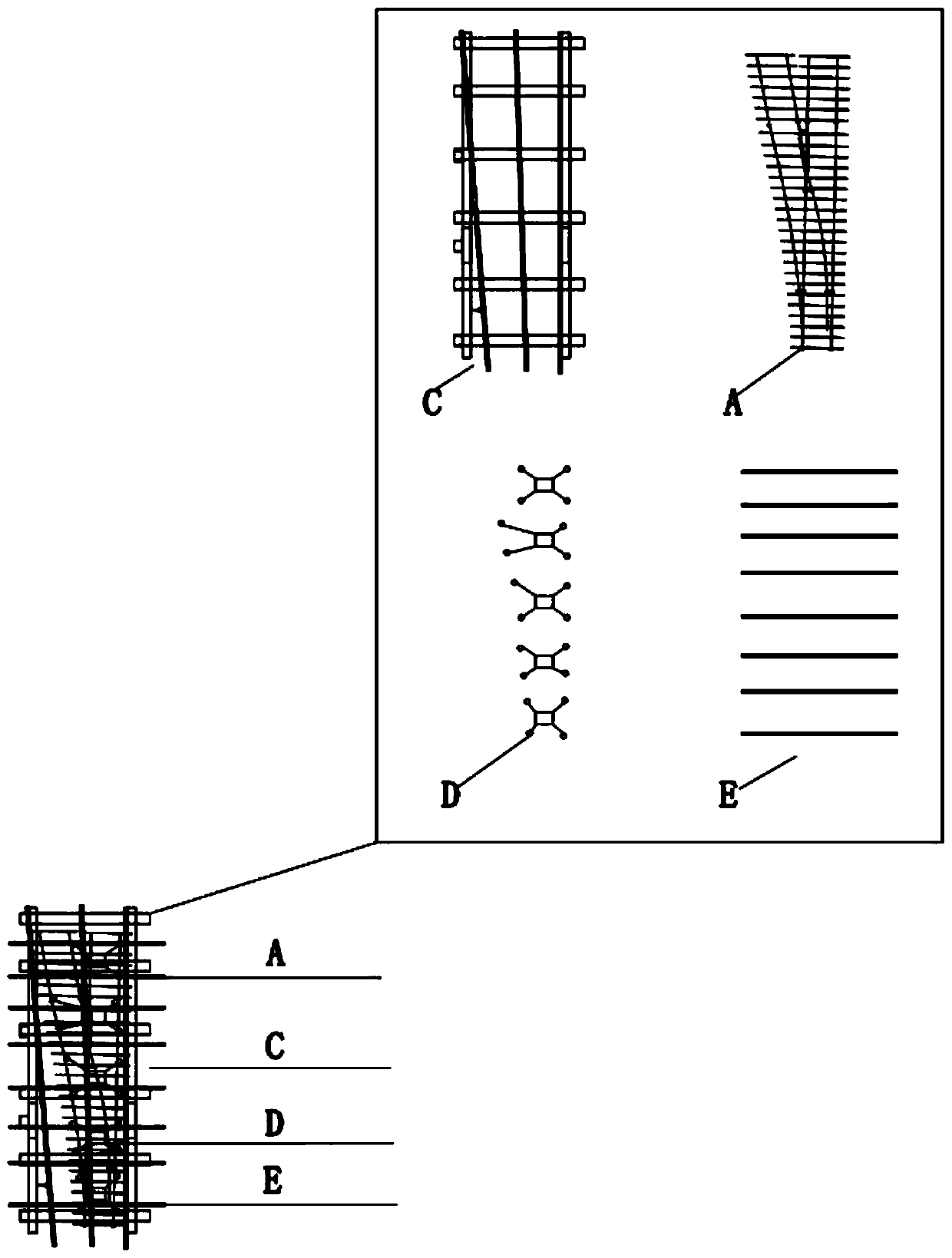

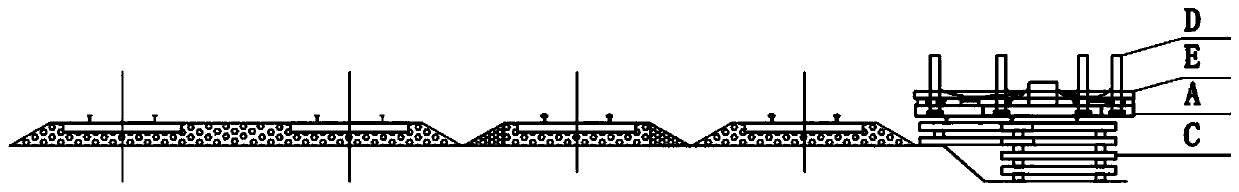

[0064] This embodiment provides a rapid construction device for a turnout when an existing station is being renovated, including a pre-paved platform, a lifting device, a running device and a traction device; a turnout sleeper is pre-laid on the pre-paved platform for laying a turnout; the lifting device It is fixed on the rail of the turnout and is used to drive the turnout to go up and down; the running device is used to realize the lateral movement and the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com