C-type wingceltis bar and cross beam end adjustable connecting part

An adjustable, connecting piece technology, applied in the direction of building, building structure, etc., can solve the problems of small adjustable range of connecting piece, unable to adapt to the connection between C-shaped purlins and beams, etc., so as to improve the locking range and reduce the possibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

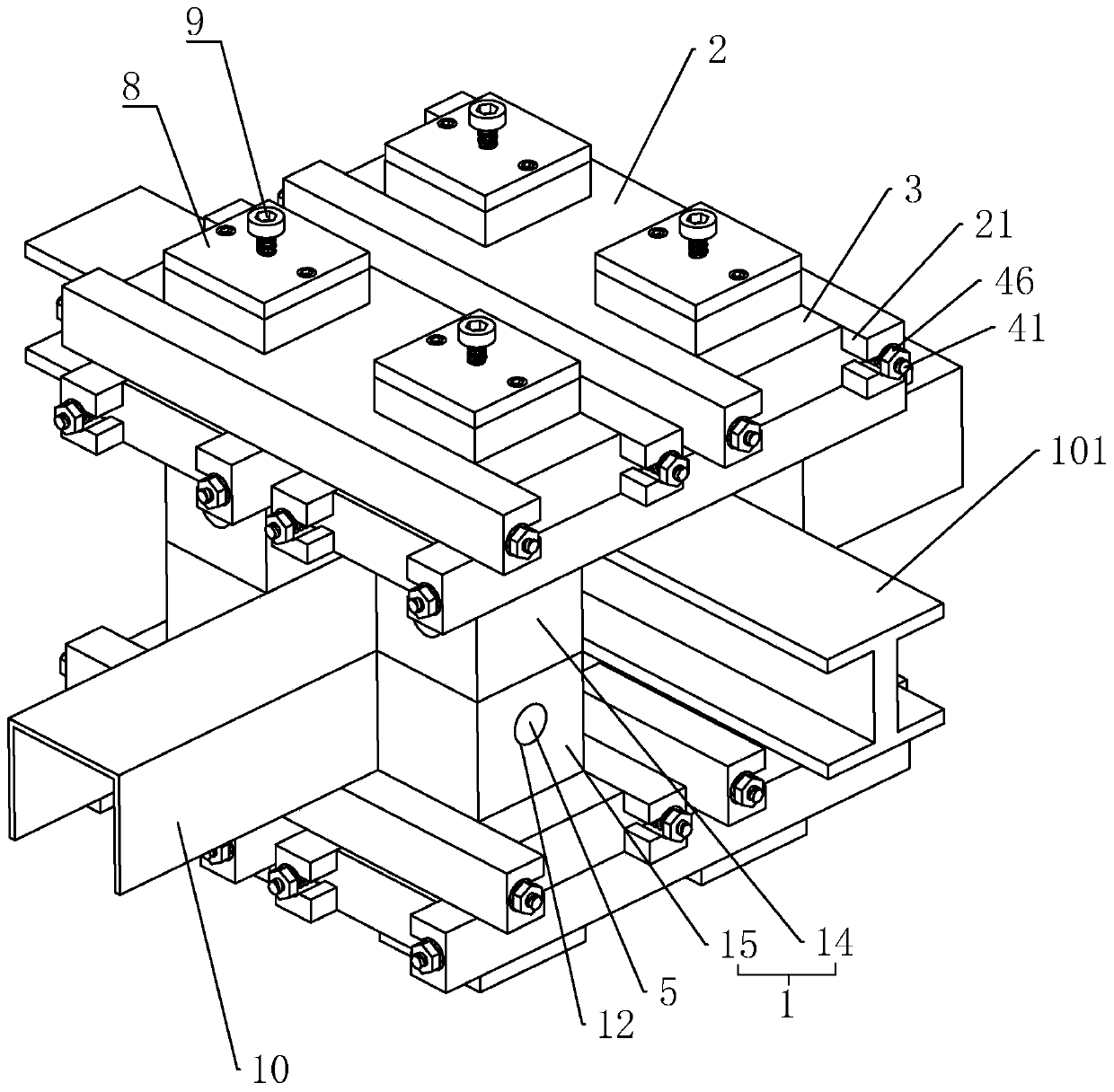

[0037] The invention discloses an adjustable connecting piece at the end of a C-shaped sandalwood bar and a beam. figure 1 , including a positioning column 1 and a limiting plate 2, the positioning column 1 is vertically arranged with four, and the ends of the C-shaped sandalwood bar 10 and the beam 101 are stacked up and down in sequence, and the two are interspersed in the shape of a "ten". Between the positioning columns 1.

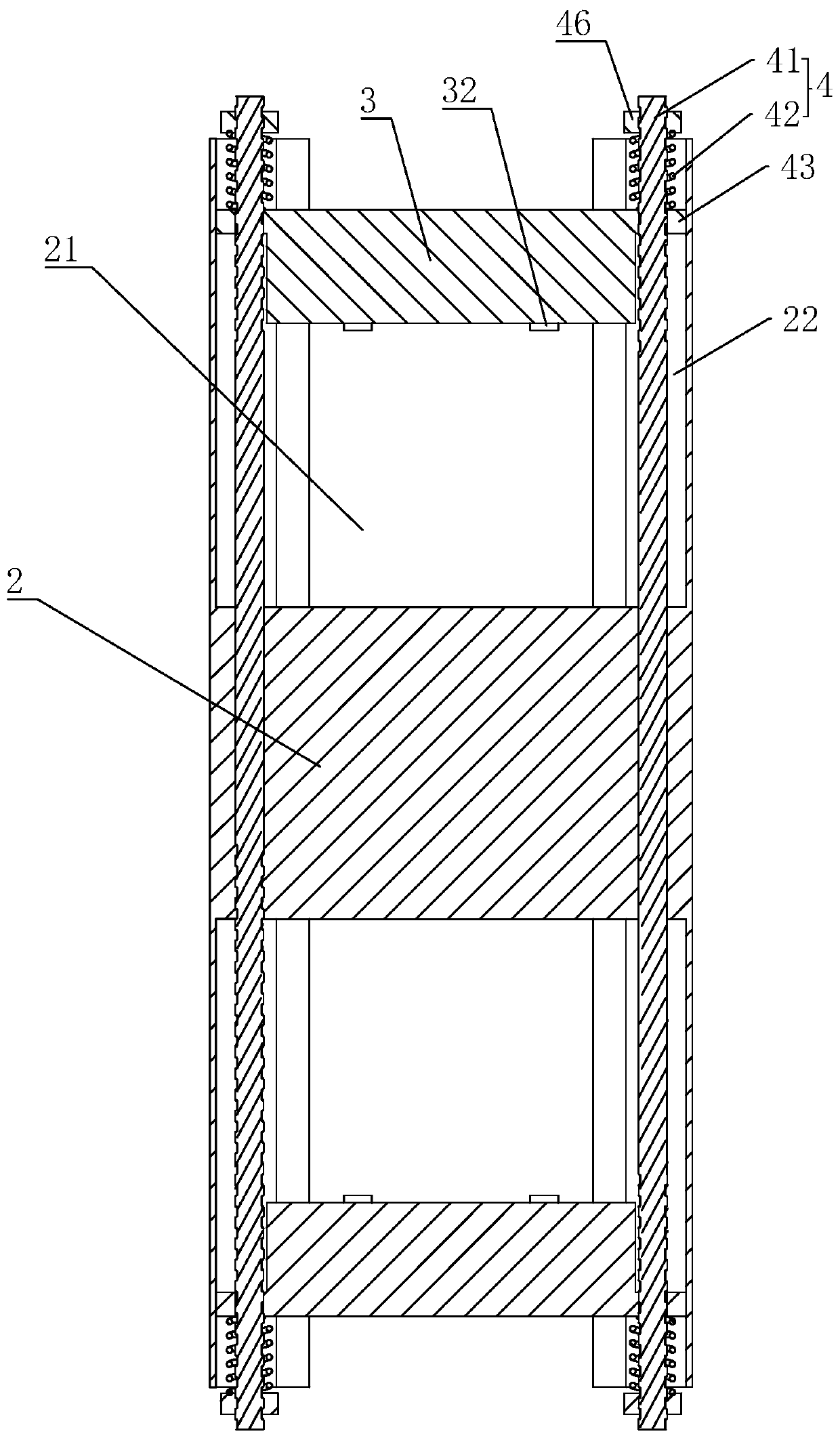

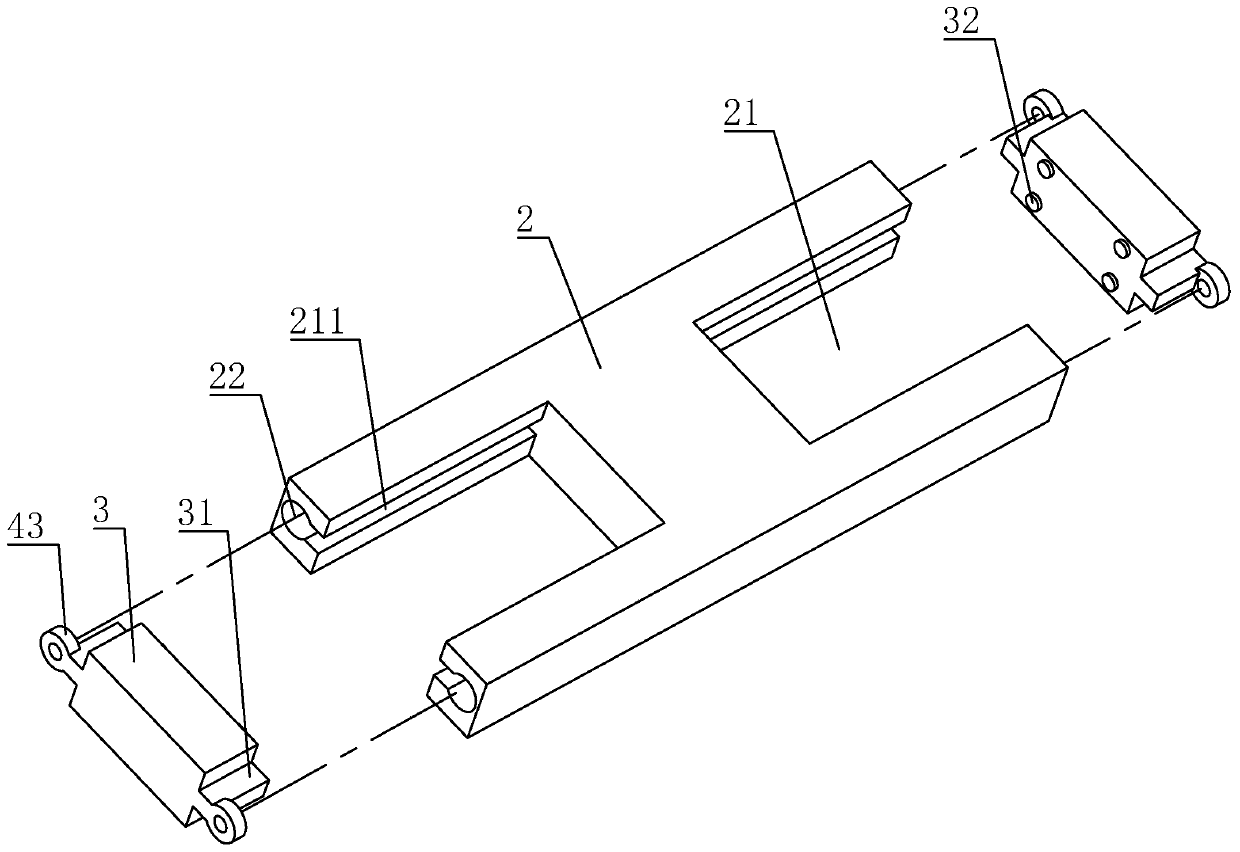

[0038] refer to figure 2 and image 3 , the limiting plate 2 is arranged horizontally, and its two ends are respectively provided with adjustment openings 21 along its length direction, and a locking block 3 which can slide along the length direction of the limiting plate 2 is arranged in the adjusting opening 21 . In order to improve the stability of the locking block 3 during the sliding process, guide sliders 31 are fixedly connected to the two sides of the locking block 3 parallel to the length direction of the limiting plate 2, and the adjustment...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 lies in that the locking component 4 is different. refer to Figure 8 , in this embodiment, the locking assembly 4 includes a positioning screw 44 and a deadlock nut 45, the positioning screw 44 is fixedly connected to the side of the positioning column 1 facing the locking block 3, and the locking block 3 is provided with a positioning screw 44 Through the through hole, the deadbolt nut 45 is threadedly connected to the shank where the positioning screw 44 passes through the locking block 3 . After the locking block 3 abuts against the positioning column 1, the positioning screw 44 passes through the perforation, and the staff screw-connects the locking nut 45 on the positioning screw 44, and through the locking of the locking nut 45, the positioning column is realized. 1 and the connection between the locking block 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com