Damping stair formwork for building construction and assembling method thereof

A technology of building construction and assembly method, applied in the direction of building, building structure, formwork/formwork/work frame, etc., can solve the problems of low construction efficiency and inaccessible stairs, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

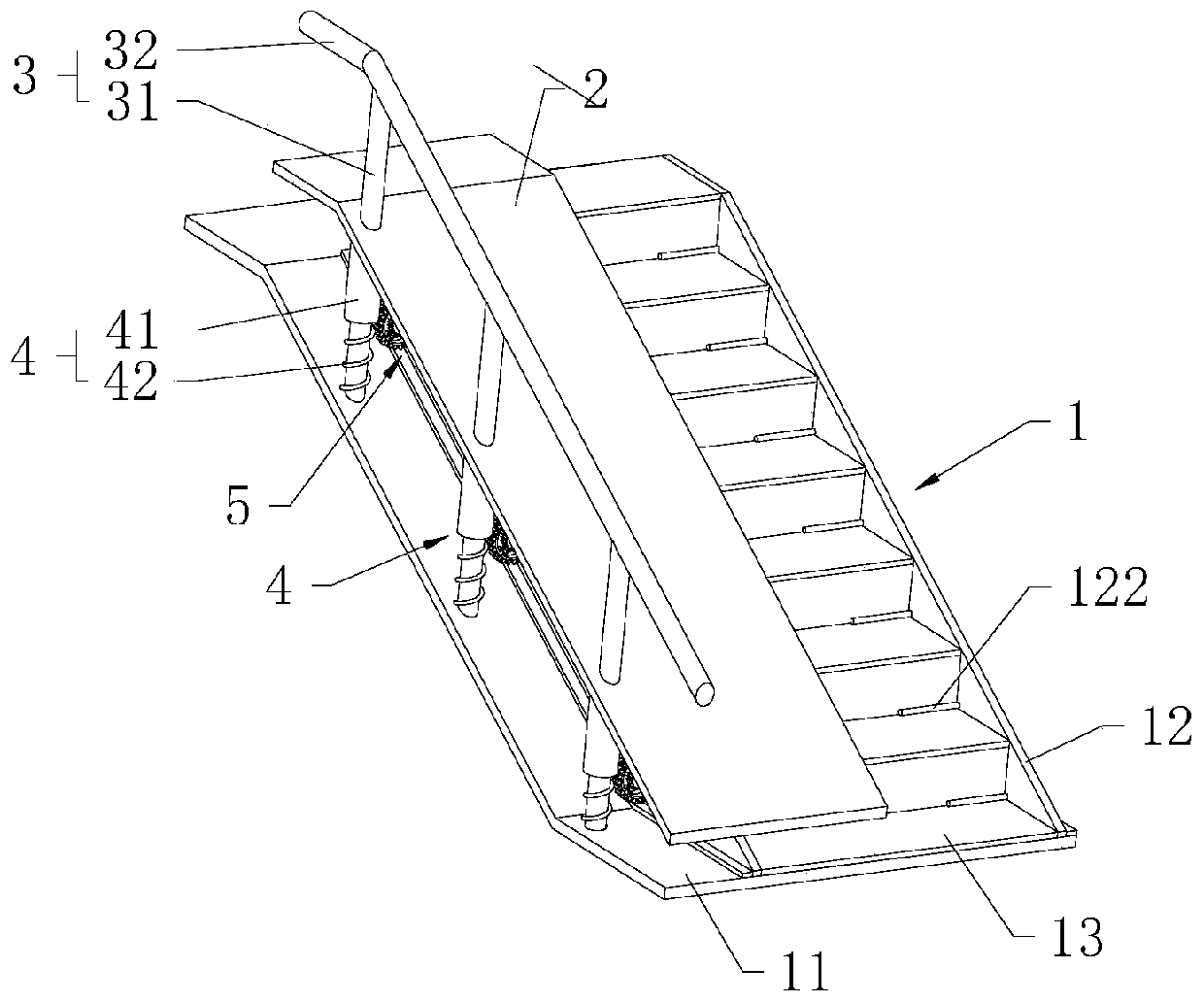

[0055] refer to figure 1 , 2 , is a shock-absorbing stair formwork for building construction disclosed by the present invention, including a main body 1, a pedal 2 and a guardrail 3, the main body 1 is erected between adjacent floors, and a pouring space 14 is provided in the main body 1, which is used for filling Concrete realizes the pouring of the stairs. The pedal 2 is arranged above the body 1 for workers to pass through and go up and down the floors, realize simultaneous pouring and maintenance of multiple stairs, and improve construction efficiency. At the same time, the guardrail 3 is arranged on one side of the body 1. It is beneficial to improve the safety of workers walking on the pedal 2.

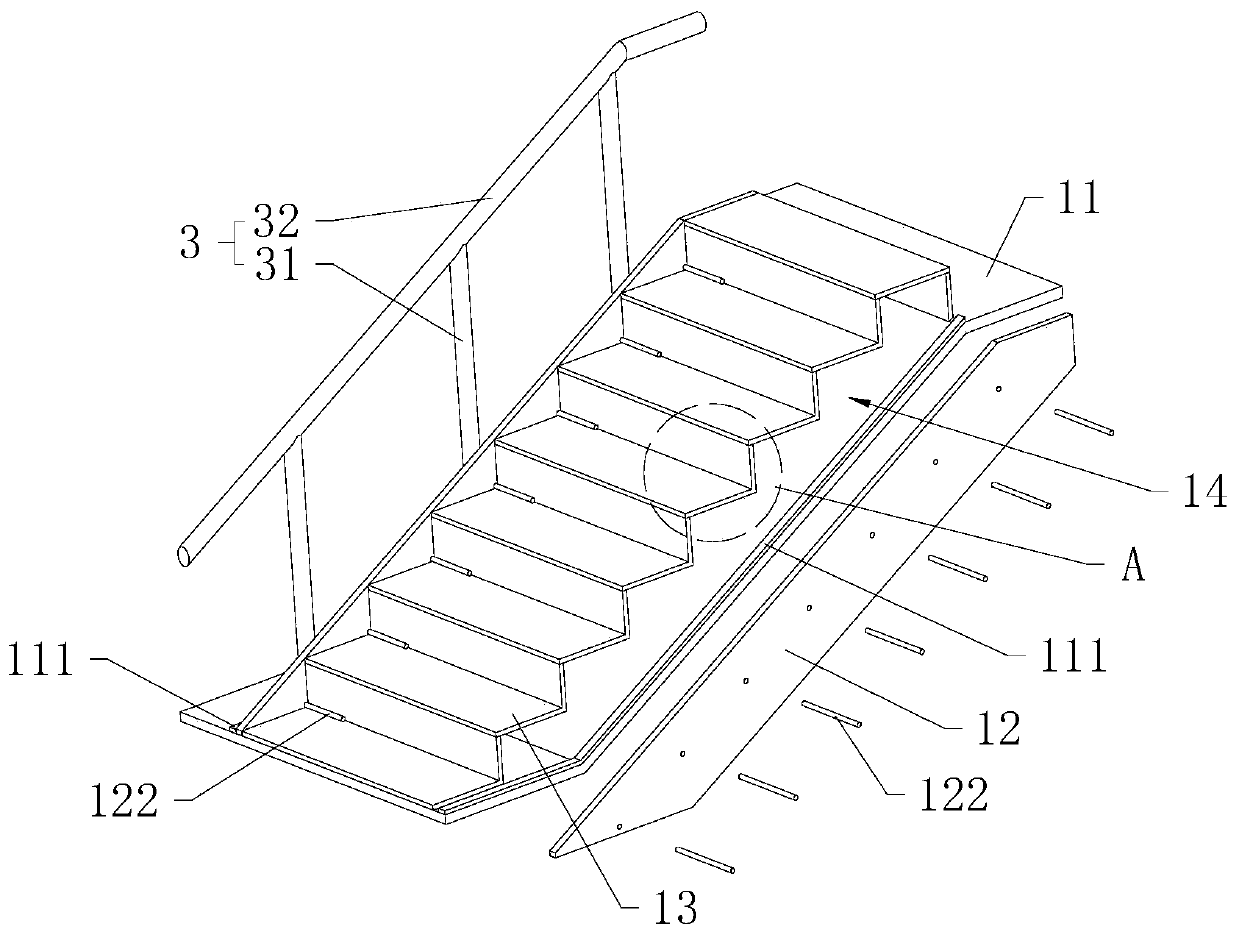

[0056] refer to figure 2 , the body 1 includes a bottom plate 11, a side plate 12 and a cover plate 13, the bottom plate 11 is erected between adjacent floors, two side plates 12 are arranged side by side, and are located at the upper end of the bottom plate 11, refer to im...

Embodiment 2

[0078] A method for assembling a shock-absorbing stair formwork for building construction, comprising the following steps:

[0079] S1: Body 1 is fixed between adjacent floors;

[0080] S1.1: The bottom plate 11 is fixed between adjacent floors;

[0081] S1.2: The two side plates 12 are installed between the two retaining bars 111 on the bottom plate 11, and the opposite sides of the two side plates 12 abut against the retaining bars 111 respectively;

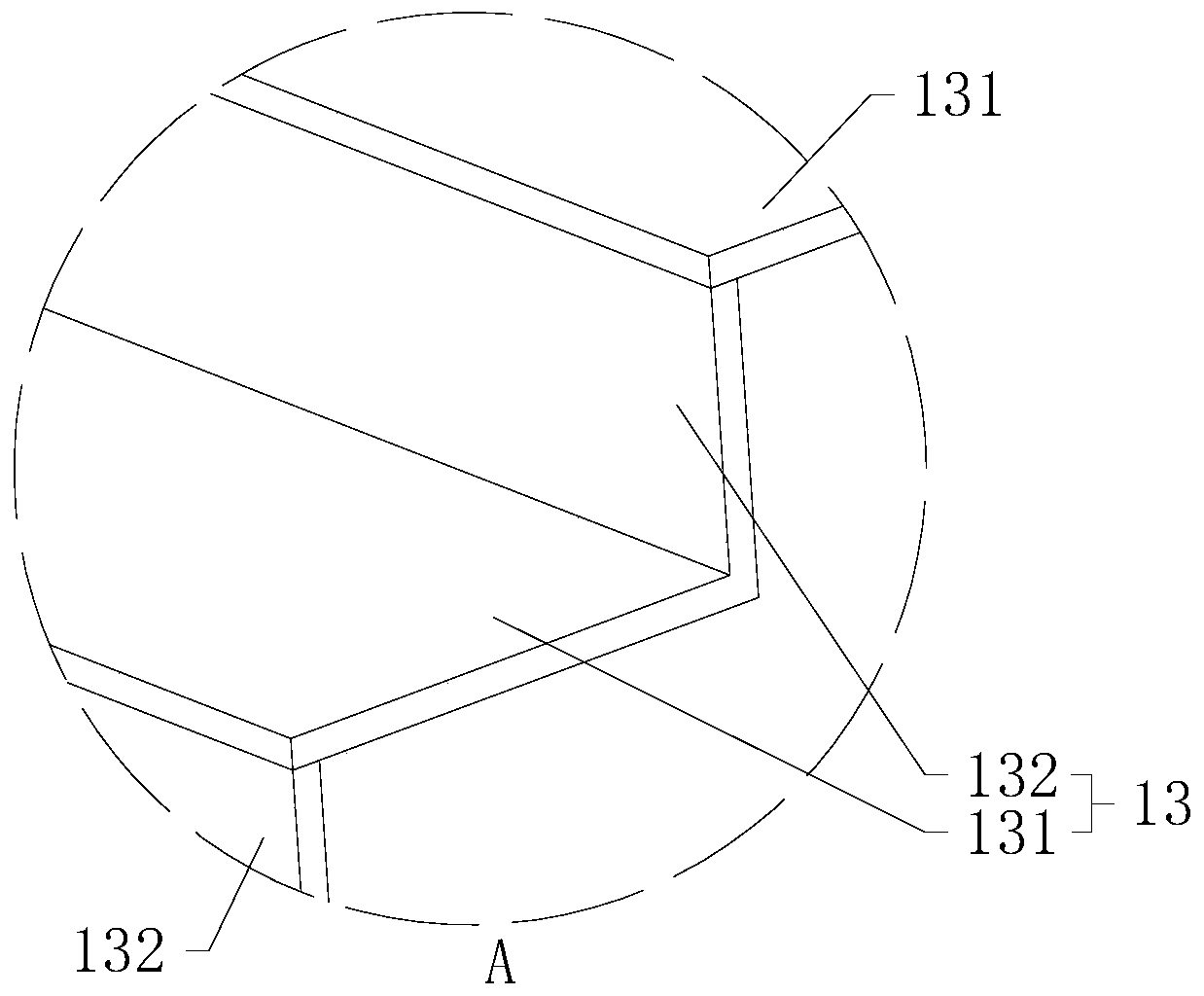

[0082] S1.3: A plurality of cover plates 13 are installed between the two side plates 12, and the two ends of the cover plates 13 are respectively embedded in the positioning grooves 121 of the two side plates 12. At the same time, the plurality of cover plates 13 And laying in turn;

[0083] S1.4: The pin 122 is inserted into the side plate 12, and the pin 122 extends between the two side plates 12, and makes the outer periphery of the pin 122 abut the cover plate 13. At the same time, the side wall of the pin 122 and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com