Shield transverse moving station crossing method

A technology of passing stations and shielding, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of inconvenient operation, low construction efficiency, and great difficulties, and achieves the improvement of construction efficiency, cost saving, and material reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

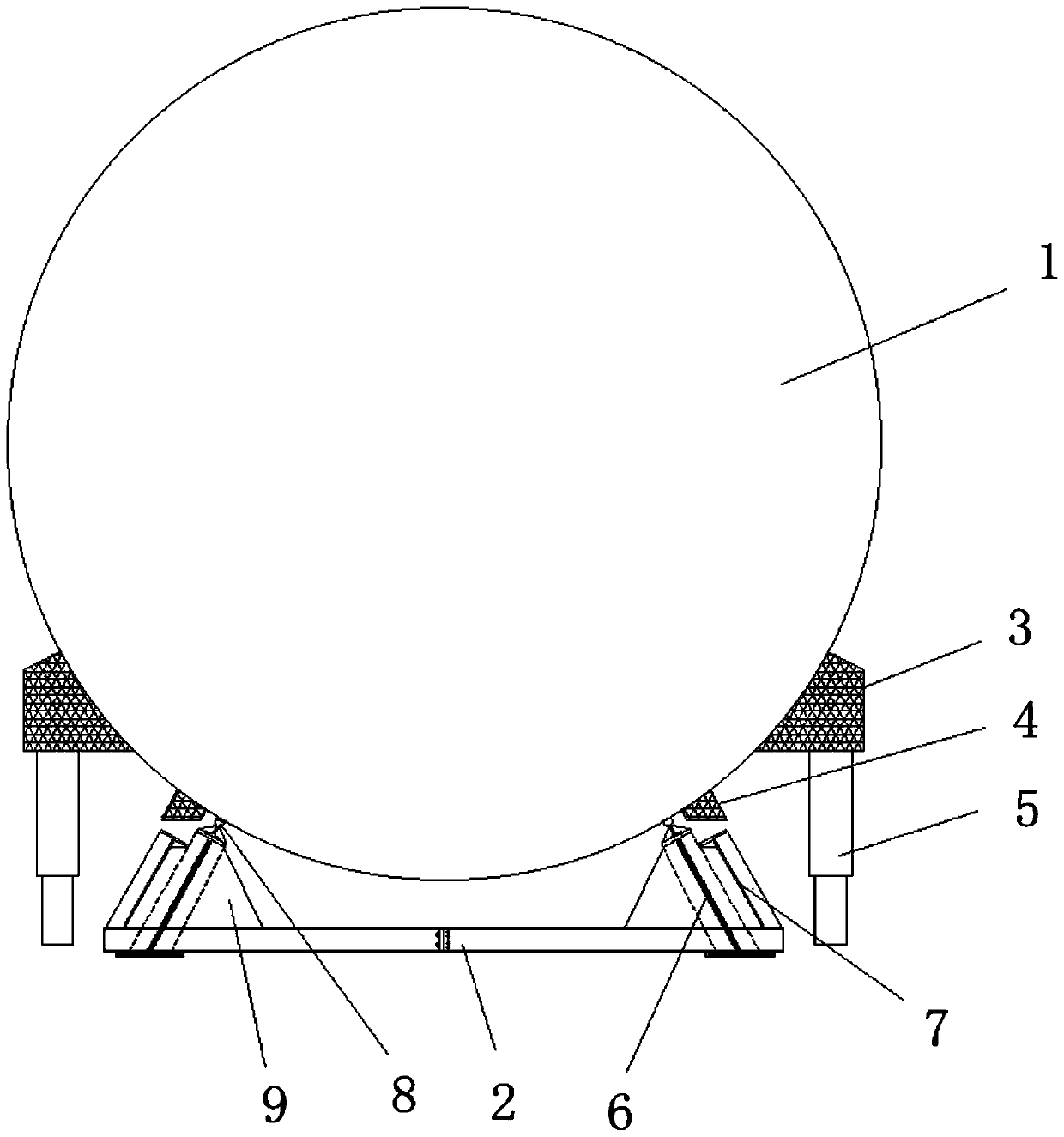

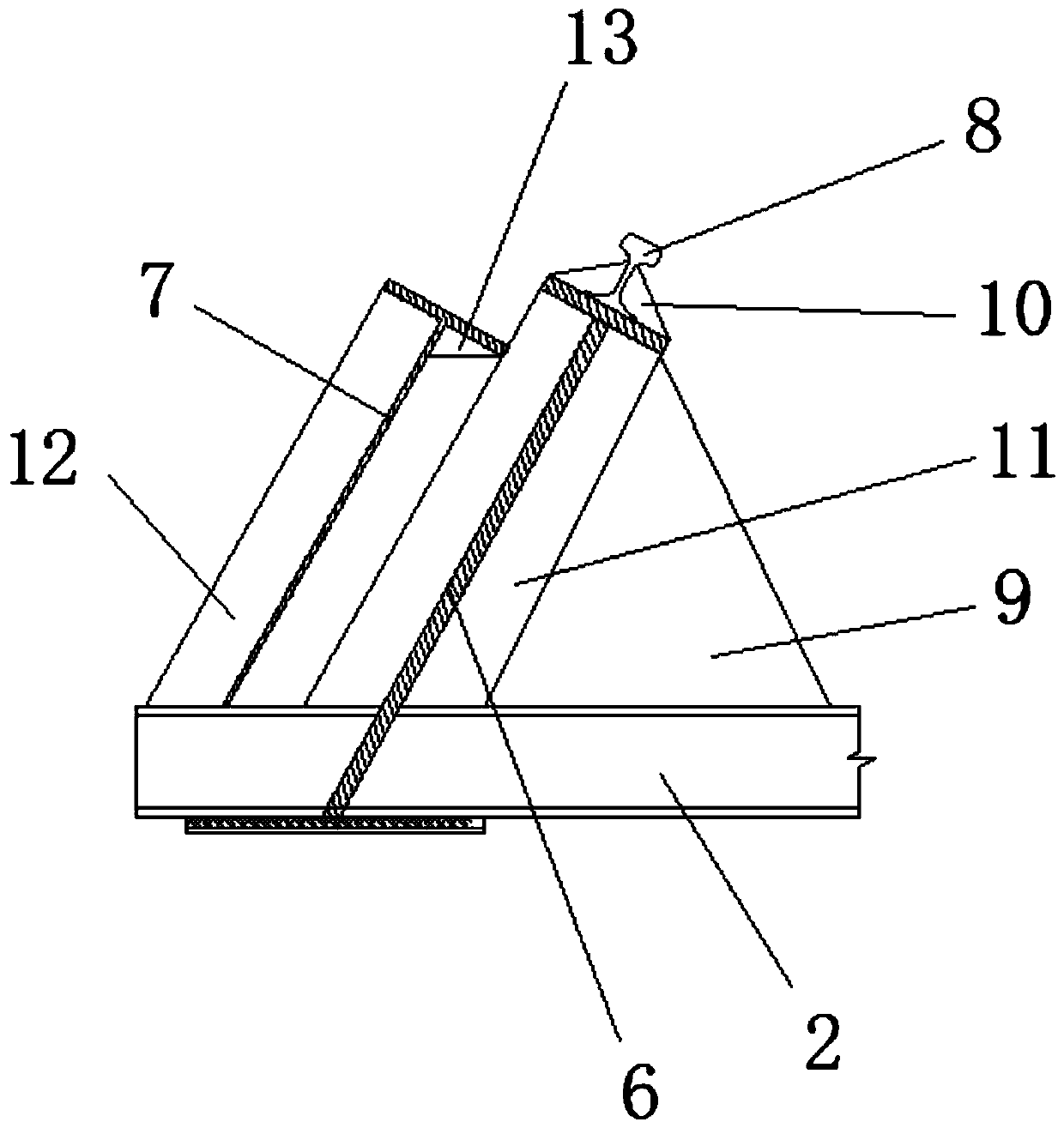

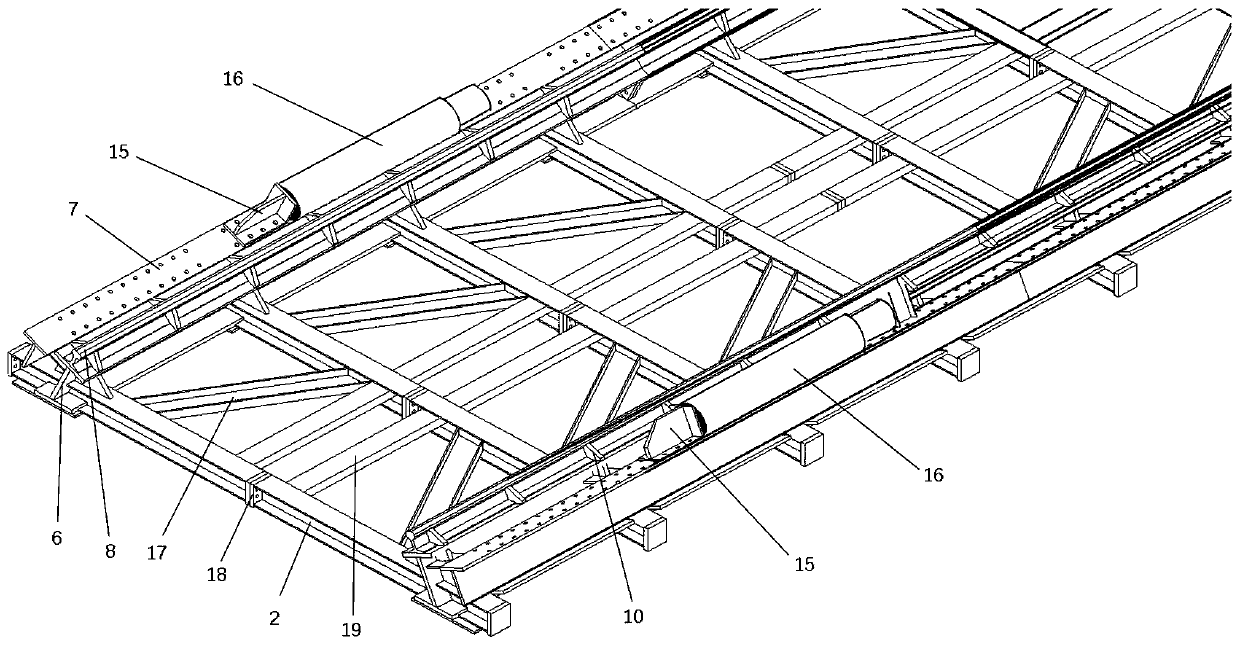

[0060] A method for shield tunneling translation, comprising the following steps:

[0061] S1: Construction preparation: install the bracket 20, set the bracket traverse hydraulic cylinder 14 on the side of the bracket 20, weld several first corbels 3 and several second corbels 4 on both sides of the lower part of the shield machine 1 , the lower end of the first corbel 3 is provided with a lifting hydraulic cylinder 5, and the side of the second corbel 4 is a longitudinal hydraulic cylinder 16 with the same axial direction as the shield machine 1;

[0062] S2: placing the shield machine 1 on the bracket 20;

[0063] S3: Horizontal movement of the shield machine 1: firstly control the elongation of the lifting hydraulic cylinder 5 to lift the shield machine 1; then control the extension of the bracket lateral movement hydraulic cylinder 14 to make the bracket 20 translate to the right (for the convenience of description, this The example only takes Figure 6-9 The direction ...

Embodiment 2

[0084] A method for shield tunneling translation, comprising the following steps:

[0085] S1: Construction preparation: install the bracket 20, set the bracket traverse hydraulic cylinder 14 on the side of the bracket 20, weld several first corbels 3 and several second corbels 4 on both sides of the lower part of the shield machine 1 , the lower end of the first corbel 3 is provided with a lifting hydraulic cylinder 5, and the side of the second corbel 4 is a longitudinal hydraulic cylinder 16 with the same axial direction as the shield machine 1;

[0086] S2: placing the shield machine 1 on the bracket 20;

[0087] S3: Horizontal movement of the shield machine 1: firstly control the elongation of the lifting hydraulic cylinder 5 to lift the shield machine 1; then control the extension of the bracket lateral movement hydraulic cylinder 14 to make the bracket 20 translate laterally; then control the shield machine 1 The lifting hydraulic cylinder 5 on one side is shortened so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com