Automatic drying system for rice

A drying system, rice technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of inconvenient and time-consuming discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

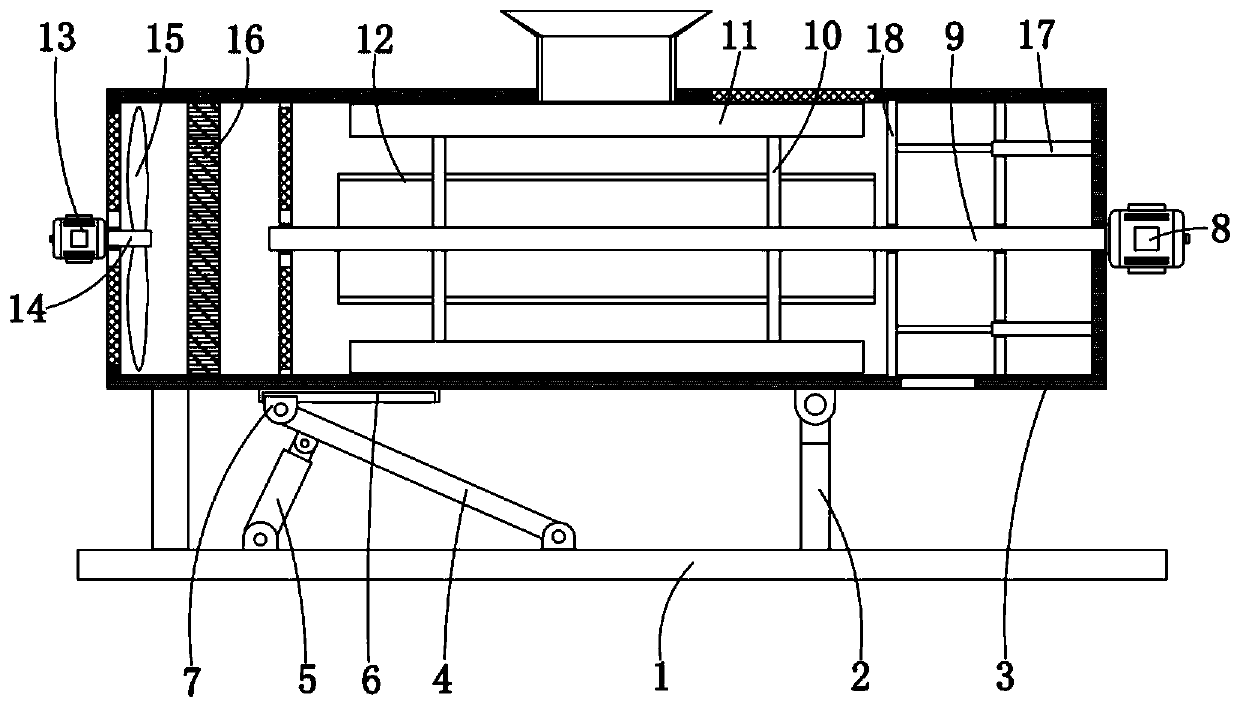

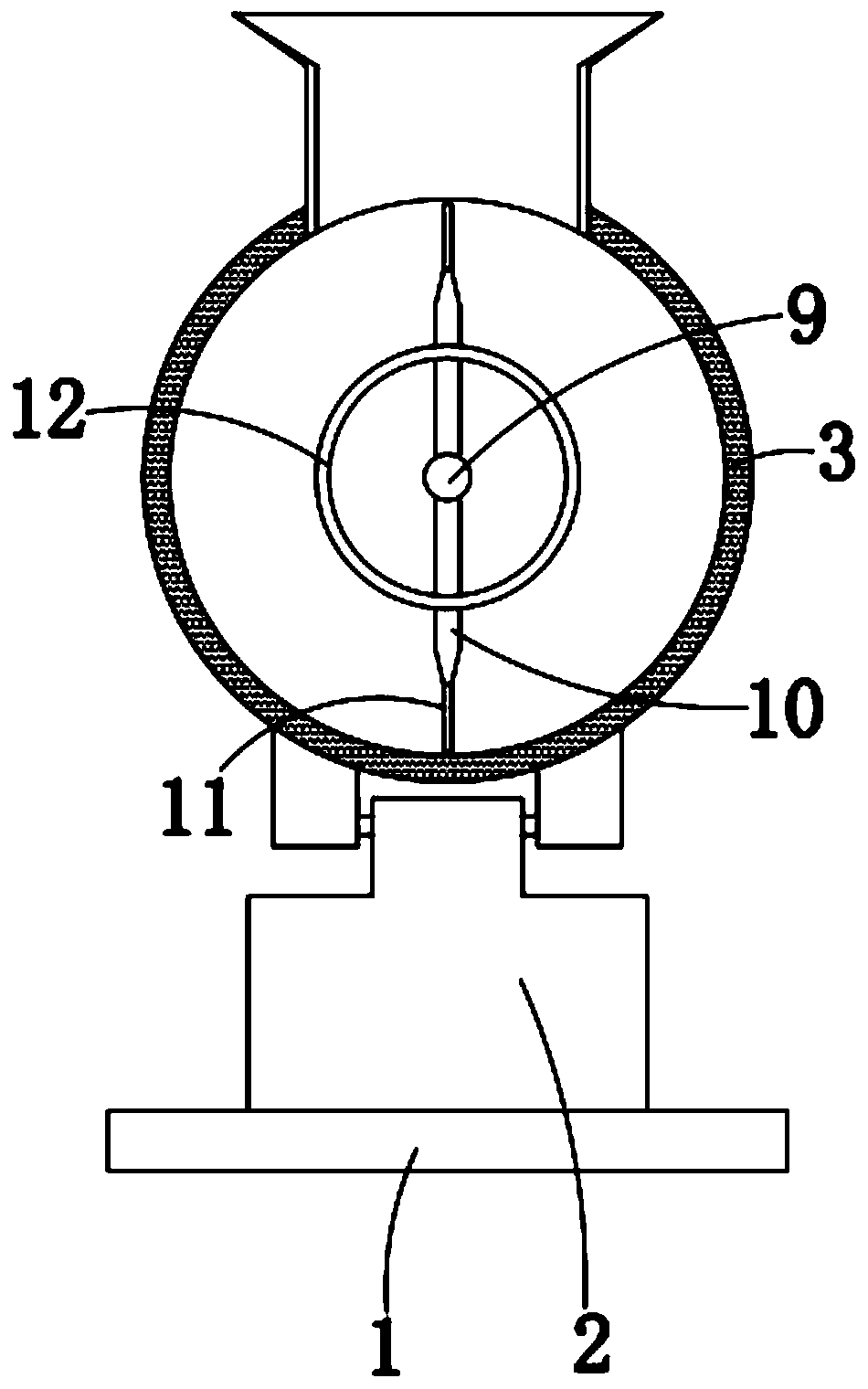

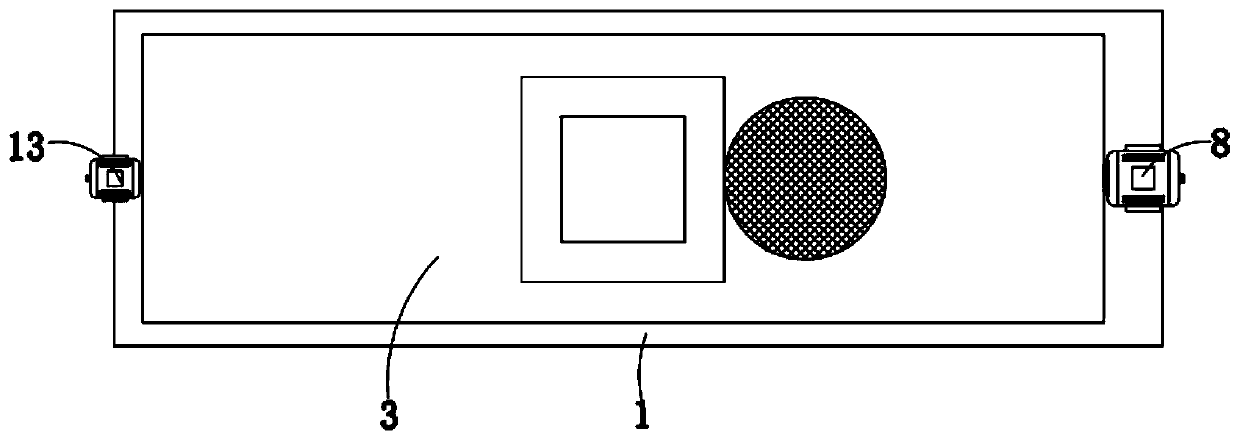

[0028] Please refer to Figure 1-Figure 3 , in the first embodiment of the present invention, the rice automatic drying system includes: a base 1; a first support plate 2, the first support plate 2 is fixedly installed on the top of the base 1; a cylinder 3, the cylinder 3 is rotatably installed on the top of the first support plate 2; the rocker 4 is rotatably installed on the top of the base 1; the hydraulic push rod 5 is rotatably installed on the top of the base 1, and the The output rod of the hydraulic push rod 5 is rotatably connected to the bottom of the seesaw 4; the slide rail 6 is fixedly installed on the bottom of the cylinder body 3; the limit slider 7 is slidably installed on the On the slide rail 6, the bottom of the limit slider 7 is rotationally connected with the top of the seesaw 4; the first motor 8, the first motor 8 is fixedly installed on the end of the cylinder 3; the rotating rod 9, the rotating The rod 9 is installed in the cylinder body 3 in rotatio...

no. 2 example

[0041] Based on the rice automatic drying system provided in the first embodiment of the present application, the second embodiment of the present application proposes another automatic rice drying system, the second embodiment is only the preferred mode of the first embodiment, the second The implementation of the embodiment has no effect on the individual implementation of the first embodiment.

[0042] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0043] Please refer to Figure 4-Figure 5 , in the second embodiment of the present invention, the rice automatic drying system includes: two fixed mounts 19, both fixed mounts 19 are fixedly installed on one side of the cylinder body 3, and the two fixed mounts 19 are fixedly installed with the same A conveying cylinder 20, the top of the conveying cylinder 20 is fixedly equipped with a third motor 21, and a conveying screw wheel 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com