An agricultural grain drying device with dust removal function

A drying device and agricultural technology, applied in drying, drying machine, heating device and other directions, can solve the problems affecting the processing quality of the drying device, the single function of the drying device, and the lack of dust removal structure, etc., to achieve rich functions and improved Processing quality, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

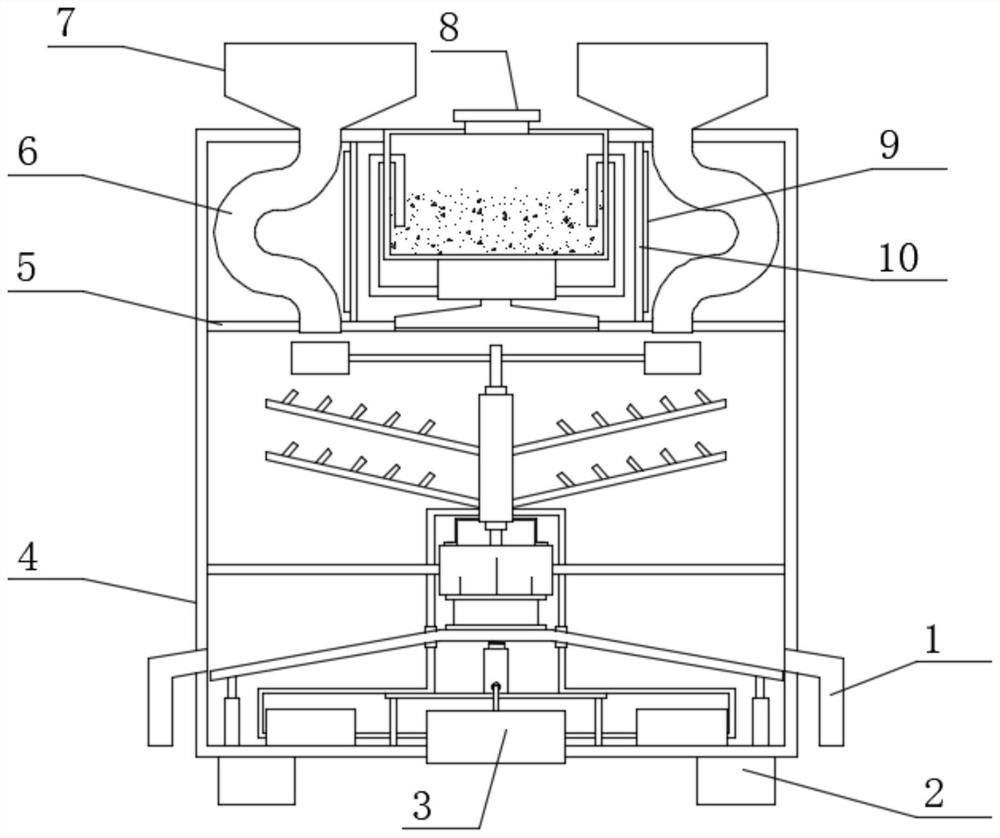

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: an agricultural grain drying device with dust removal function, comprising a housing 4, the bottom end of the housing 4 is welded with a discharge pipe 1, and the two ends of the lower surface of the housing 4 are passed through bolts The support foot 2 is fixed, and the material of the support foot 2 is rubber. When in use, the support foot 2 acts as a shock absorber. The top of the shell 4 is welded with a partition plate 5, and the two ends of the upper surface of the shell 4 are welded with a lower hopper 7. The bottom of the hopper 7 is welded with a blanking elbow 6, which runs through the partition plate 5. The bottom end of the blanking elbow 6 is fixedly connected to the partition plate 5 by welding. The housing 4 The bottom end is provided with a drying mechanism 3;

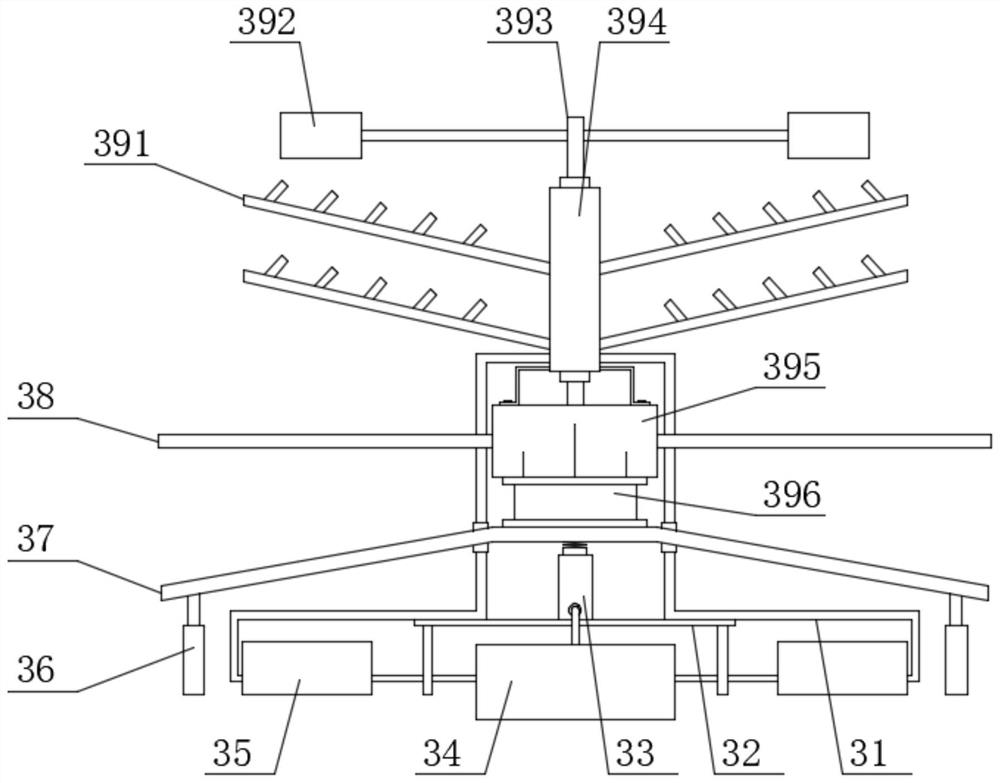

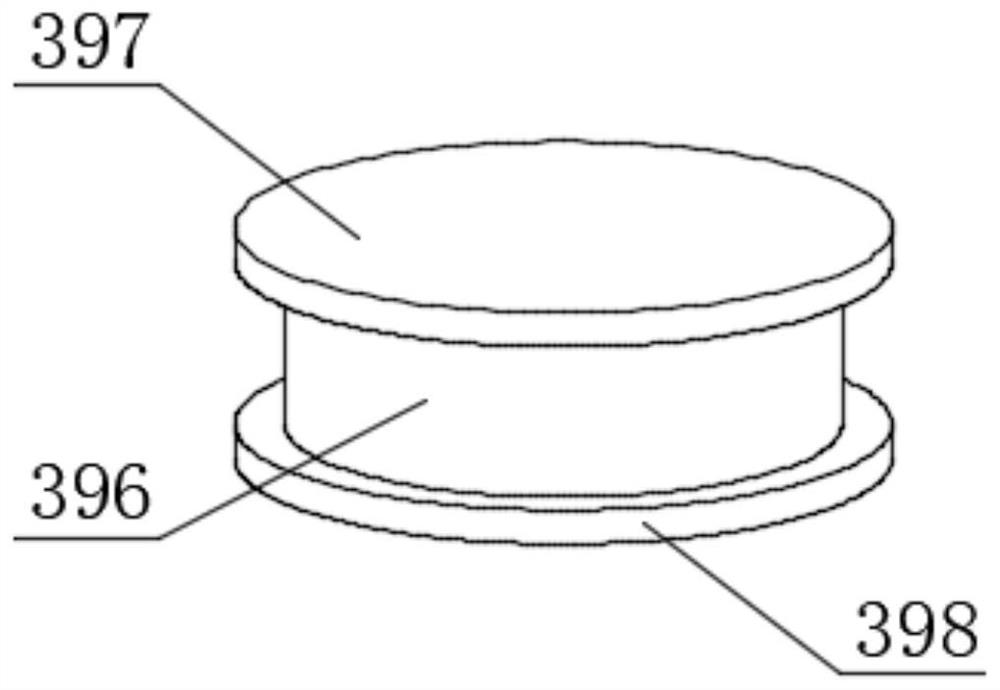

[0025] The drying mechanism 3 includes a second electric heating plate 37, the two ends of the lower surface of the ...

Embodiment 2

[0035] On the basis of Embodiment 1, in order to prevent the negative pressure fan 82 from sucking the grain into the dust cover 81, in this embodiment, preferably, the bottom end of the dust cover 81 is provided with a filter screen 87, and the material of the filter screen 87 is stainless steel. , the filter screen 87 is fixedly connected with the dust collection cover 81 by screws;

[0036] In order to make the filtering effect of the filter screen 87 better, in the present embodiment, preferably, the mesh diameter of the filter screen 87 is smaller than the diameter of the grain to be dried. During use, the grain is filtered through the filter screen 87 to prevent the grain from being sucked and dust in the cover 81;

[0037] In order to make the drying device have a better drying effect on grain, in this embodiment, preferably, the two ends of the upper surface of the partition plate 5 are fixed with heat insulating plates 10 by bolts, and one side of the heat insulating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com