Tensile property detection device for cable processing

A detection device and anti-stretching technology, applied in the measurement device, using stable tension/pressure to test the strength and strength characteristics of materials, etc., can solve the problems of low efficiency and poor detection accuracy, and achieve high detection efficiency and convenient use. , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

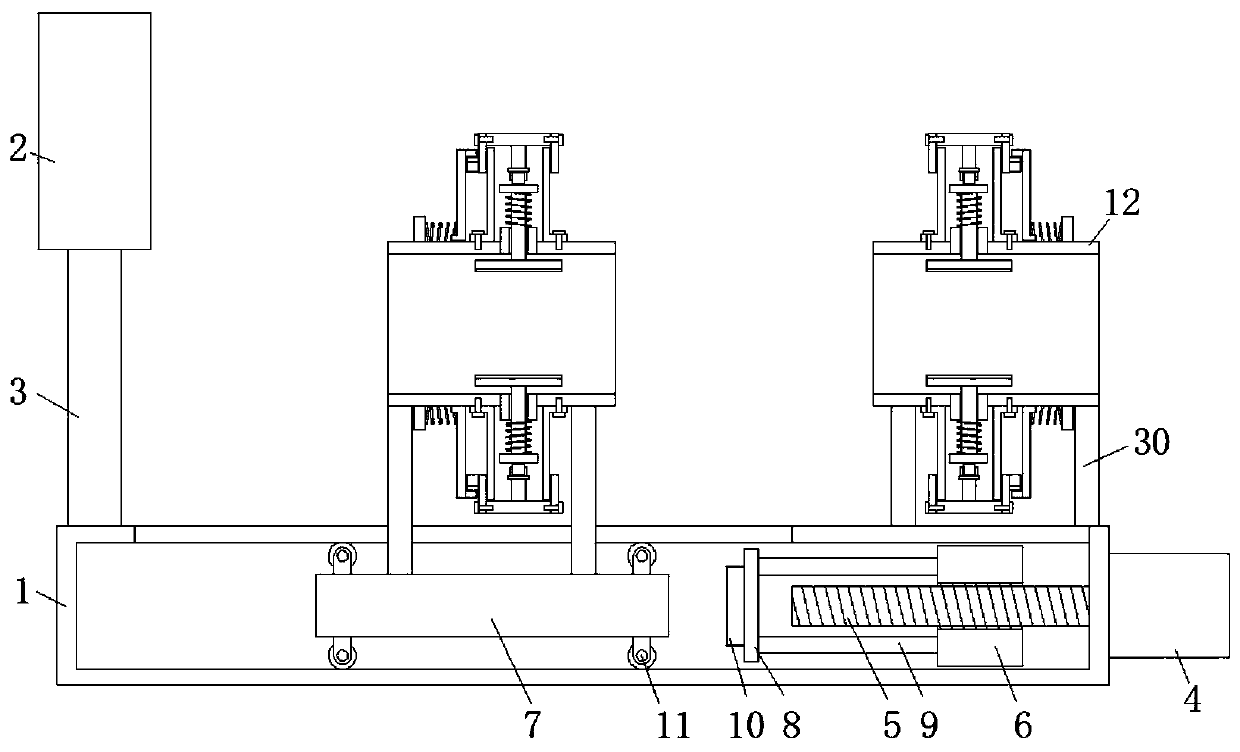

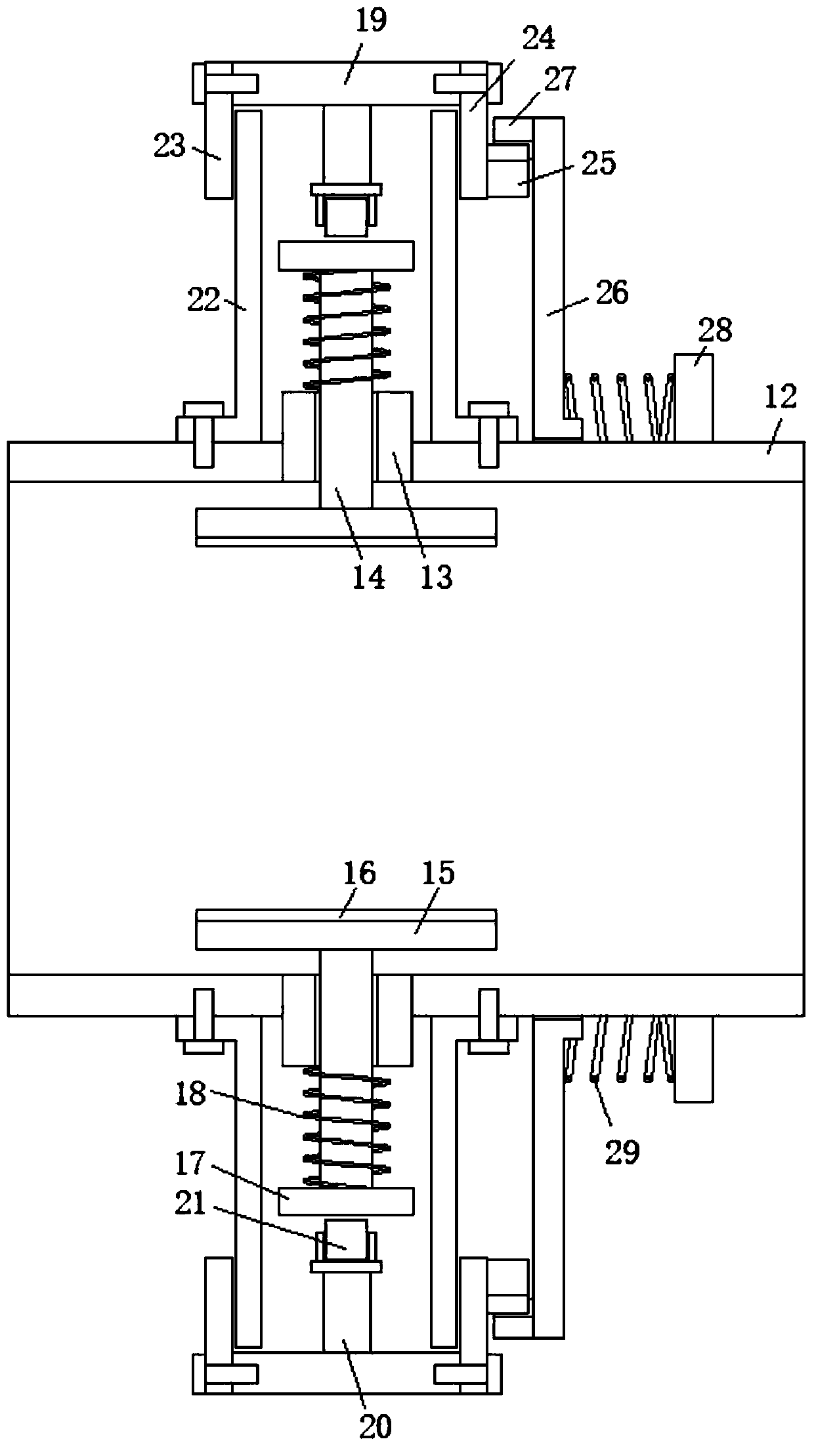

[0026] Reference Figure 1-4 , A tensile resistance testing device for cable processing, comprising a bottom box 1, an organic meter 2 is set vertically above the top end of the bottom box 1, and a meter 2 is set between the bottom side of the meter 2 and the top side of the bottom box 1. Mounting frame 3, the vertical side of the bottom box 1 is fixedly installed with a motor 4 by bolts, the output shaft of the motor 4 is connected with a threaded rod 5, and the bottom box 1 is horizontally slidingly connected with a sliding plate 6 and a sliding plate 2. 6 and the second slide plate 7 are arranged in parallel, and the plate body of the slide plate 6 is provided with a threaded through hole, and the threaded rod 5 is threaded through the threaded hole. The side of the slide plate 6 and the slide plate 2 7 close to each other is provided with a mounting plate 8 A linkage arm 9 is fixedly connected between one side of the mounting plate 8 and the sliding plate 6; the pressure se...

Embodiment 2

[0029] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side of the bottom box 1 is provided with a top hole, and one of the support frames 30 passes through the top hole.

[0030] In this embodiment, the wire barrel 12 erected by one support frame 30 is kept relatively fixed with the bottom box 1, and the wire barrel 12 erected by the other support frame 30 moves horizontally under the operation of the motor 4, thereby pulling the cable .

Embodiment 3

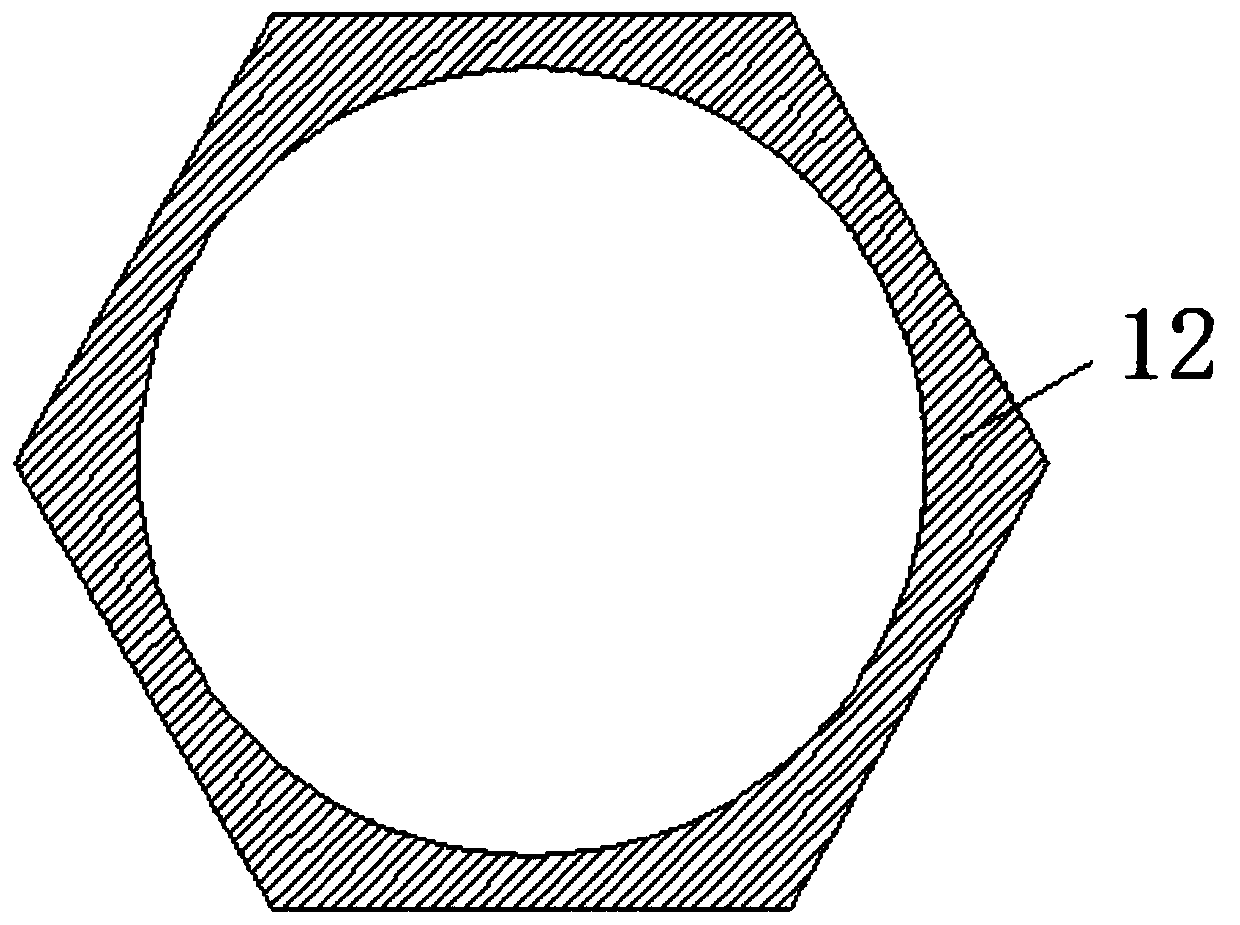

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner side of the slip ring 26 is a polygonal structure, and the inner wall of the slip ring 26 is connected to the outer side of the wire barrel 12 in sliding contact.

[0033] In this embodiment, after people control the slip ring 26 to move horizontally with one hand, the second gear ring 27 and the gear ring one 25 are disengaged, and at the same time, the slip ring 26 restricts the rotation of the spool 12 through the polygonal structure. When the other hand is used to rotate the control ring 19, the wire barrel 12 and the control ring 19 rotate relative to each other, so that the positioning plate 15 is enclosed and fixed for the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com