Furnace assembling method for special alloy aluminum ingot production

A technology of alloy aluminum and group furnaces, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., and can solve the problems of long time for group furnaces and unfavorable results of group furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

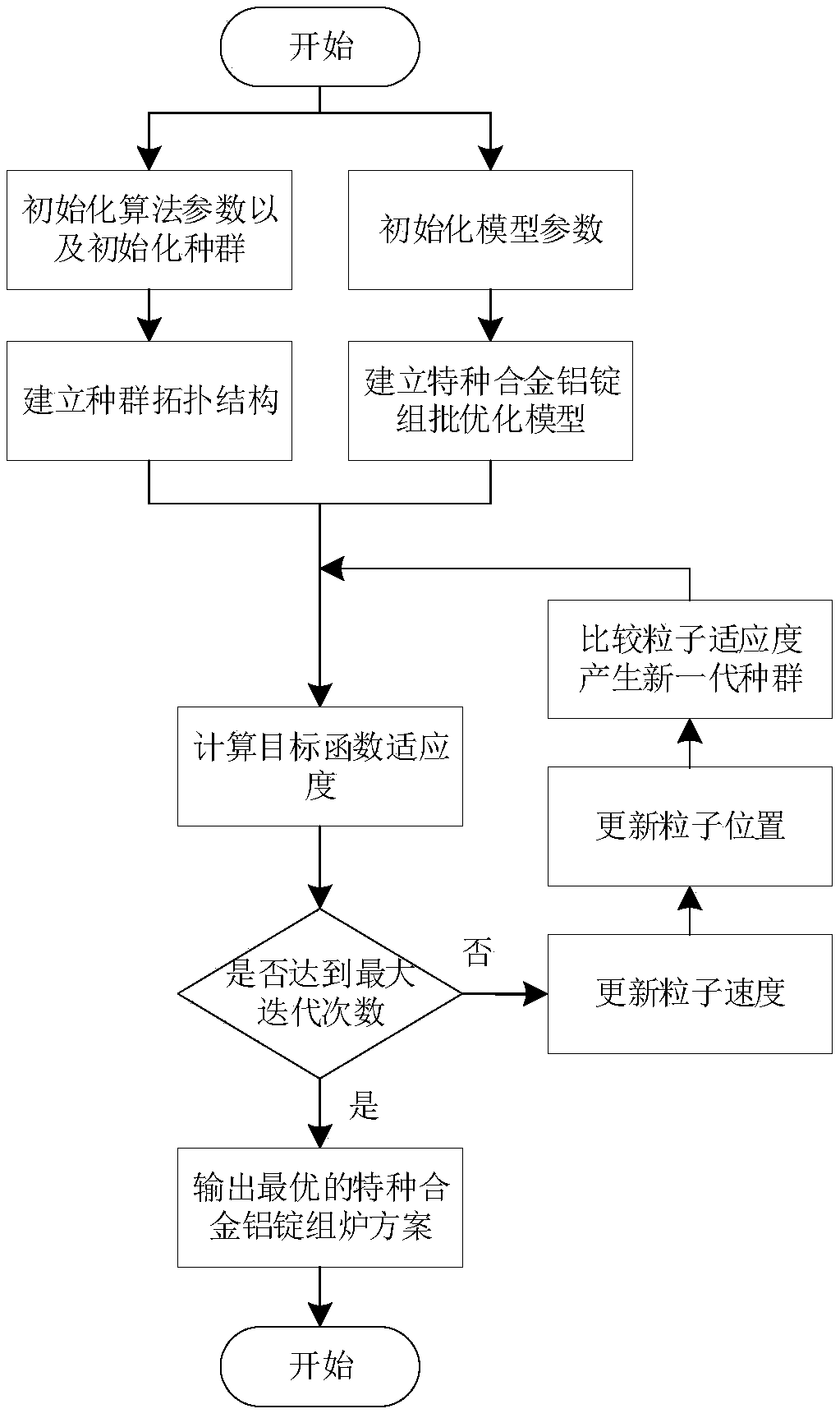

[0068] Taking the group furnace for the production of alloy aluminum ingots of a special aluminum alloy processing enterprise as an example, the method for group furnaces for the production of special alloy aluminum ingots of the present invention will be further described in conjunction with the accompanying drawings.

[0069] A furnace assembly method for the production of special alloy aluminum ingots, which is used for the first process of special aluminum alloy product production - smelting process, including the following steps:

[0070] Step 1: Initialize the group furnace information of special alloy aluminum ingots;

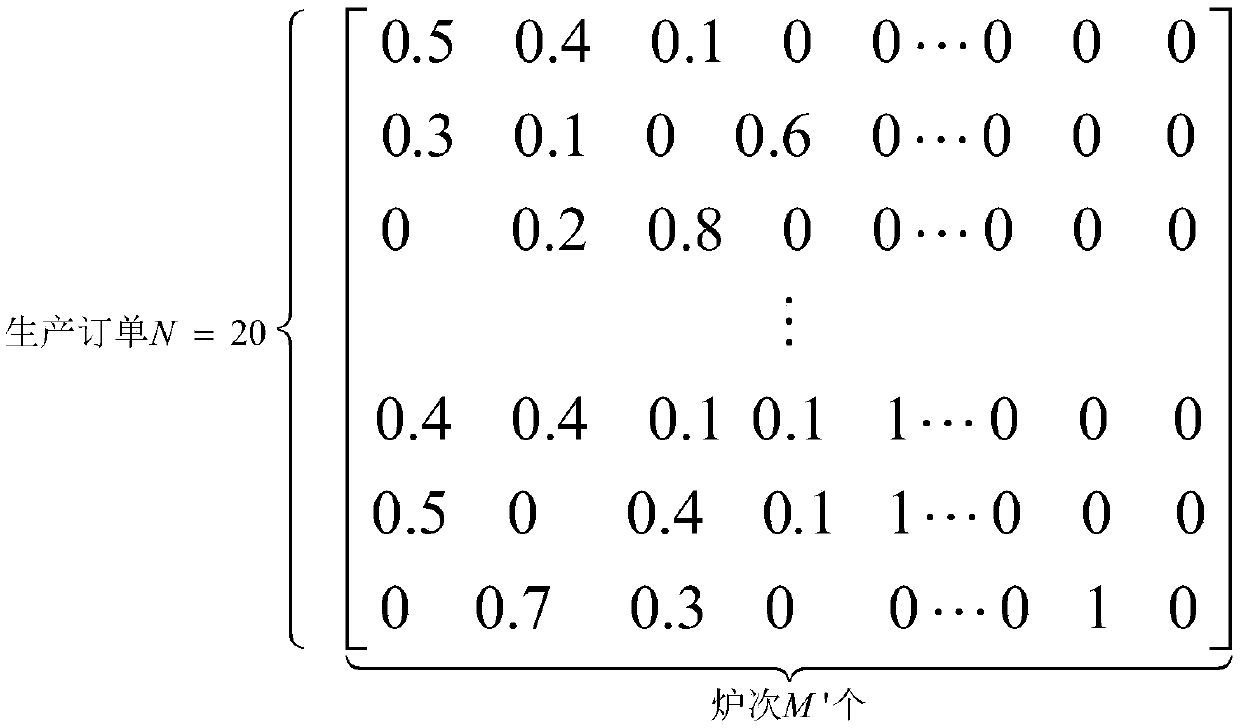

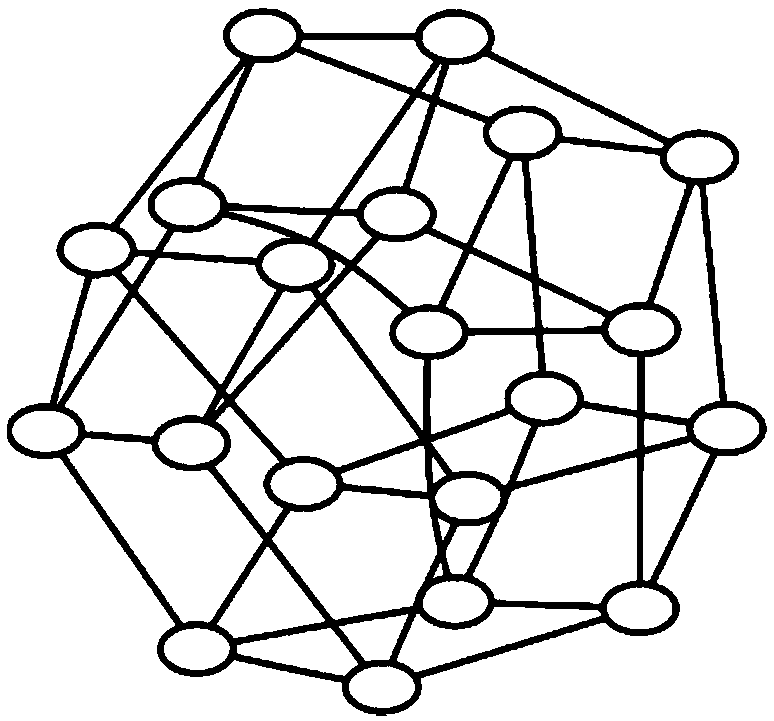

[0071] The initial information of the special alloy aluminum ingot group furnace includes: the equipment parameter information of the melting furnace, the production order information of the special alloy aluminum ingot and the initialization parameter setting of the algorithm; the equipment parameter information of the melting furnace includes: the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com