Multi-channel liquid path system

A liquid system and multi-channel technology, applied in the field of material preparation, can solve the problems of inability to meet large-scale and efficient screening of catalysts, time-consuming and labor-intensive materials, lack of reliable solutions, etc., achieve good promotion and application prospects, flexible operation, and reduce experiments effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

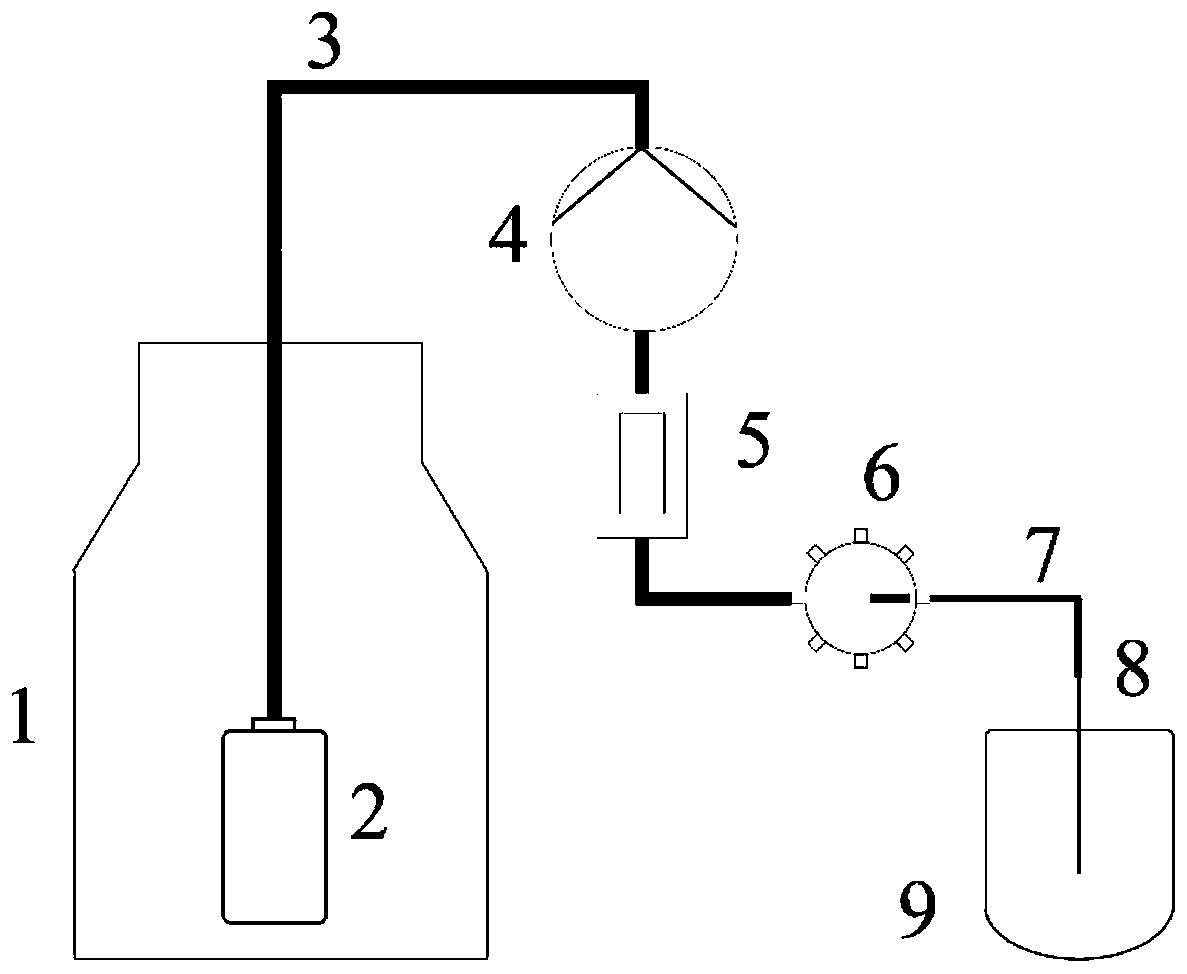

Method used

Image

Examples

Embodiment 1

[0047] refer to Figure 5-11 , in this embodiment, a plurality of mounting holes 91 for accommodating the reaction kettle 9 are provided on the mounting seat 90, and a base 92 is detachably provided on the mounting base 92, and a dispensing needle mounting block 93 is detachably provided on the base 92;

[0048] The base 92 is provided with a groove 920, and the dispensing needle mounting block 93 is fitted in the groove 920. The corner of the groove 920 on the base 92 is rotatably connected with a plectrum 921, and the distributing needle mounting block 93 is inserted into the groove. Rotate the plectrum 921 after the inside of 920, so that the plectrum 921 is pressed on the top of the dispensing needle mounting block 93, thereby fixing the dispensing needle mounting block 93 on the base 92.

[0049] The dispensing needle mounting block 93 is provided with a needle hole 94 for inserting the first reagent needle 8 and / or the second reagent needle and communicating with the rea...

Embodiment 2

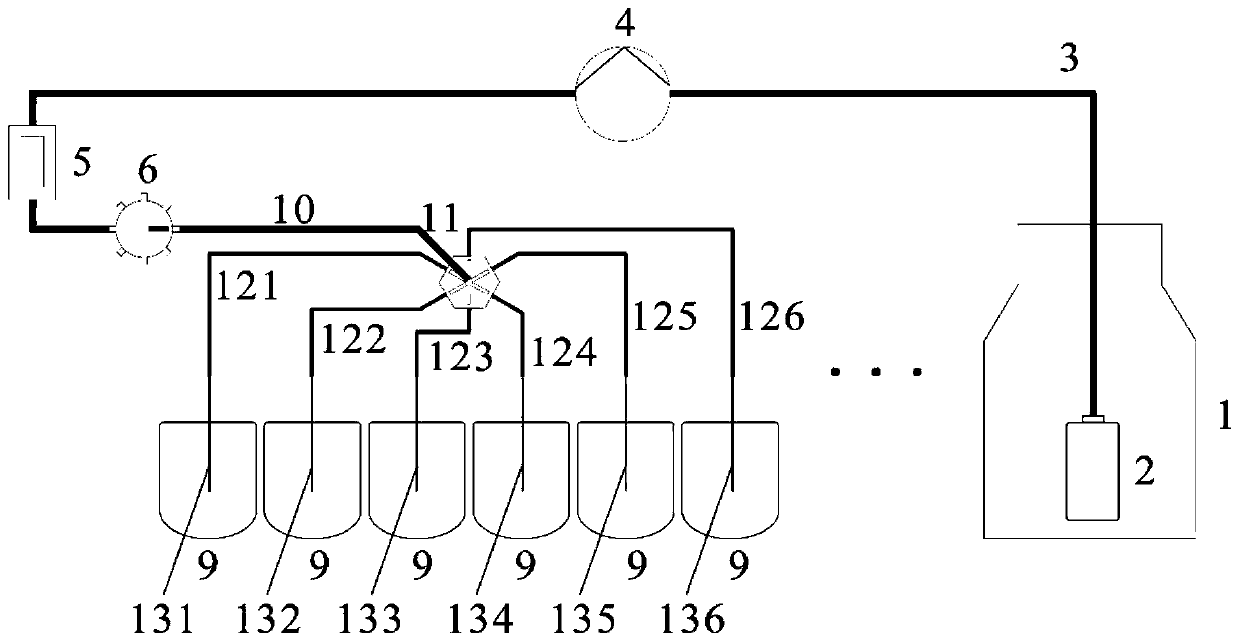

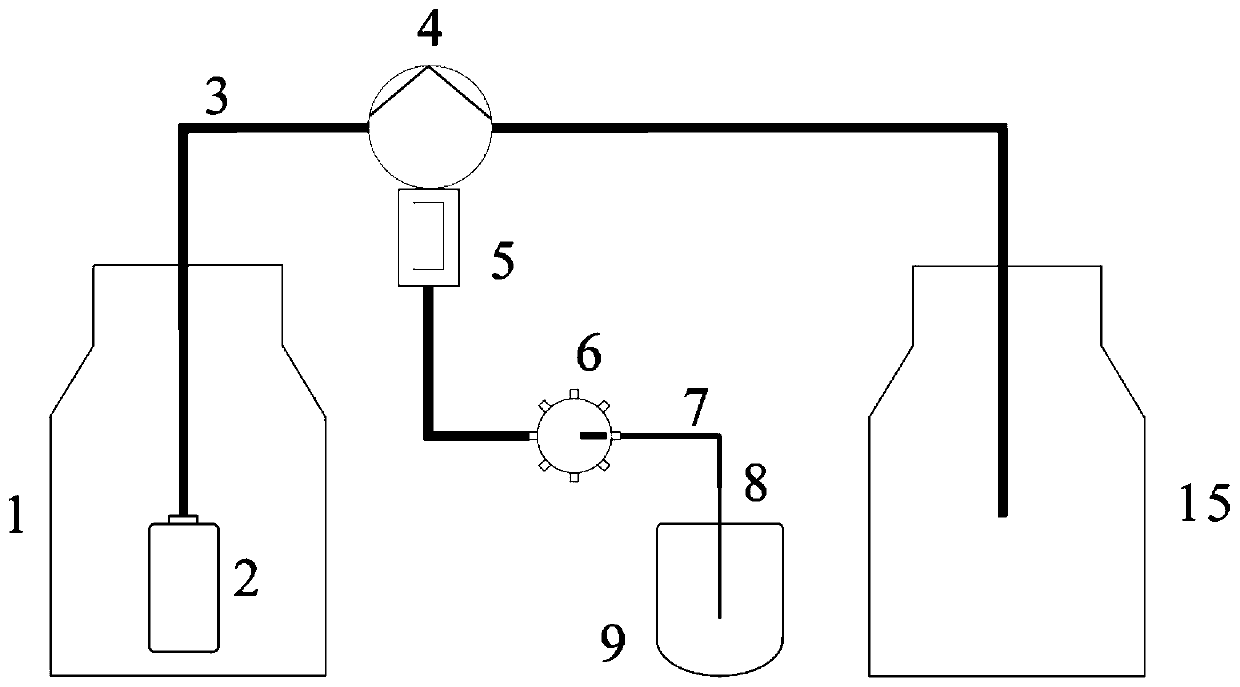

[0057] For example, in one embodiment, 12 different co-precipitation reactions need to be performed, and each co-precipitation reaction needs to add two different reaction liquids in the reaction kettle 9 . The functional requirements of the liquid circuit system are: after adding reagent 1, slowly add reagent 2 dropwise to ensure that the two reaction solutions fully react, and the proportions of reagent 1 and reagent 2 are different.

[0058] Corresponding to the liquid path distribution requirements, in this embodiment, a total of 7 precursor liquid path units, 12 single-channel reagent needle liquid path units, 2 multi-channel reagent needle liquid path units, and 12 reaction kettles 9 are included;

[0059] Among them, the reagent 1 is stored in the reaction liquid reservoir 1 of the six precursor liquid circuit units, and the reagent 2 is stored in the reaction liquid reservoir 1 of the other unit;

[0060] Among them, the channel 1 and channel 2 of the multi-channel swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com