Bending machine

A bending machine and operating table technology, applied in the field of bending machines, can solve problems such as no protective measures, dangerous situations, and component wear, and achieve the effects of simple and convenient operation, improving bending efficiency, and preventing accidental injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

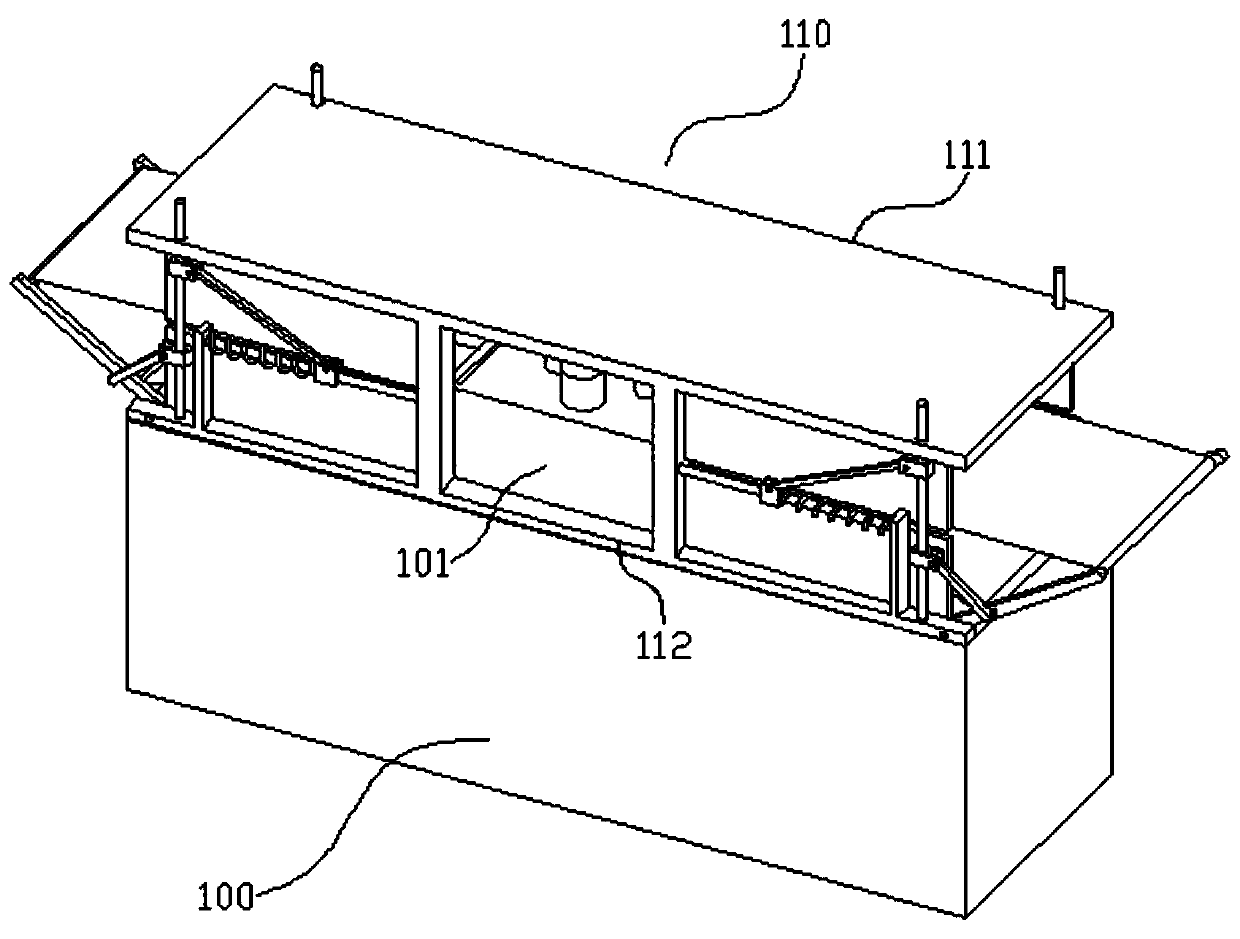

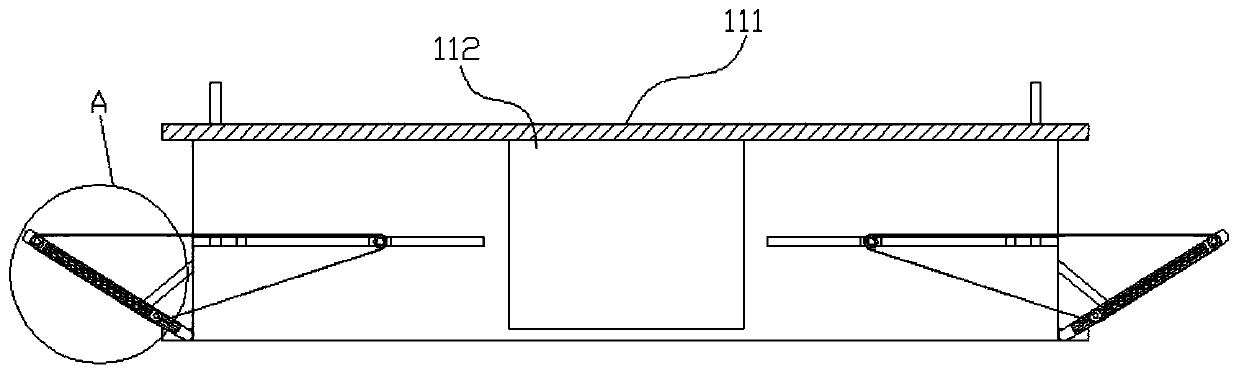

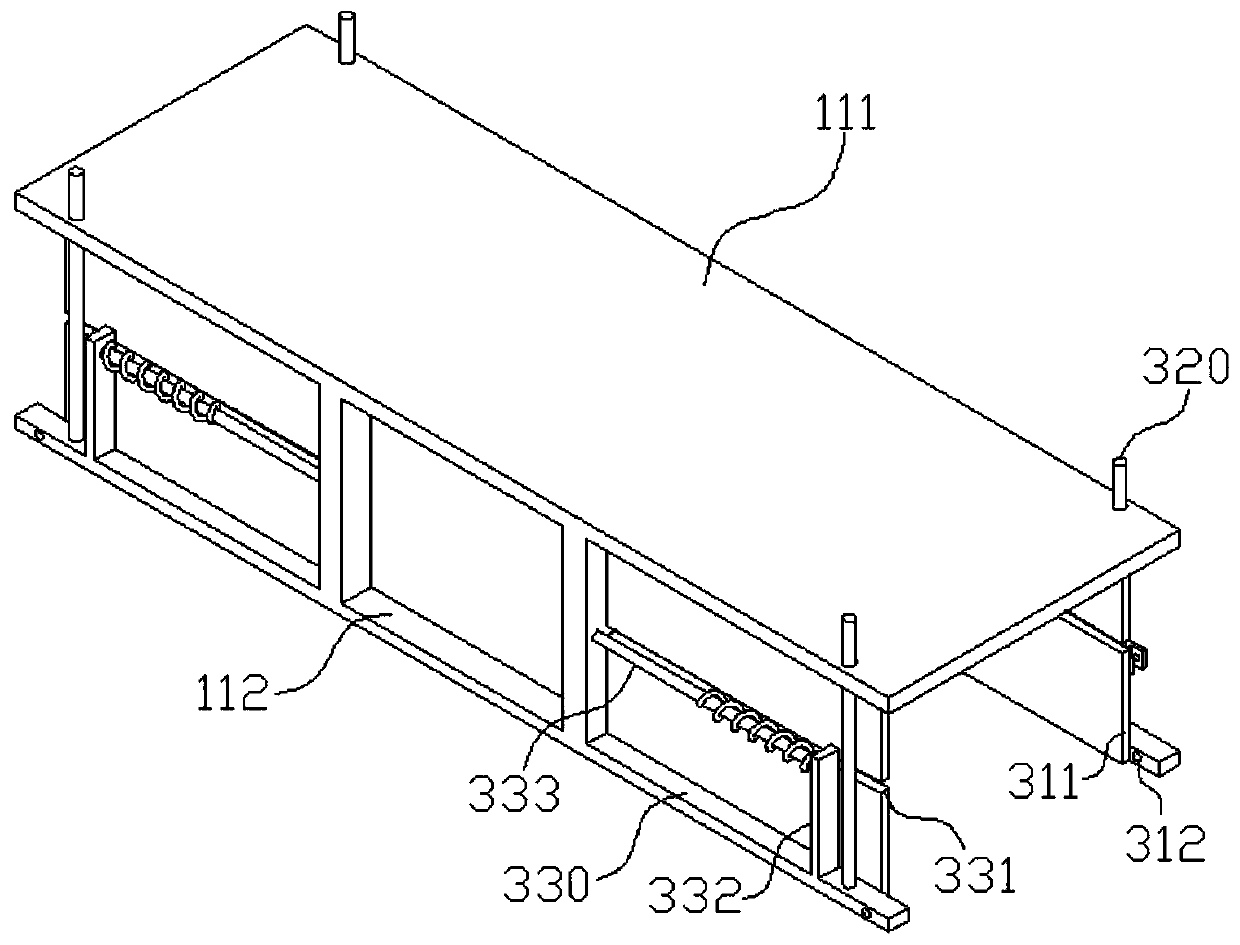

[0034] Such as Figure 1-11 As shown, this embodiment provides a bending machine, which includes a bending machine body 100, an operating console 101 is arranged above the bending machine body 100, and a protective mechanism 110 is provided on the operating console 101. The protective mechanism 110 includes two The housing 111 with an open end, the two ends of the opening of the housing 111 are provided with a connecting plate receiving groove 311, and the front and rear side walls of the connecting plate receiving groove 311 are hinged with a connecting plate 400 protruding from the housing 111, and the corresponding connecting plate There is a rotatable driving roller 410 between 400 and the upper end, and a first connecting rod 420 is connected between the corresponding connecting plate 400 and the lower end, and a rotatable first driven roller 421 is sleeved on the first connecting rod 420 , the casing 111 is provided with the second connecting rod 510 located on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com