Automatic welding device for segment reinforcement cage and construction method thereof

An automatic welding and reinforcement cage technology, which is applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of unstable welding quality of segment reinforcement cages, achieve the effect of reducing labor consumption, improving production efficiency, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

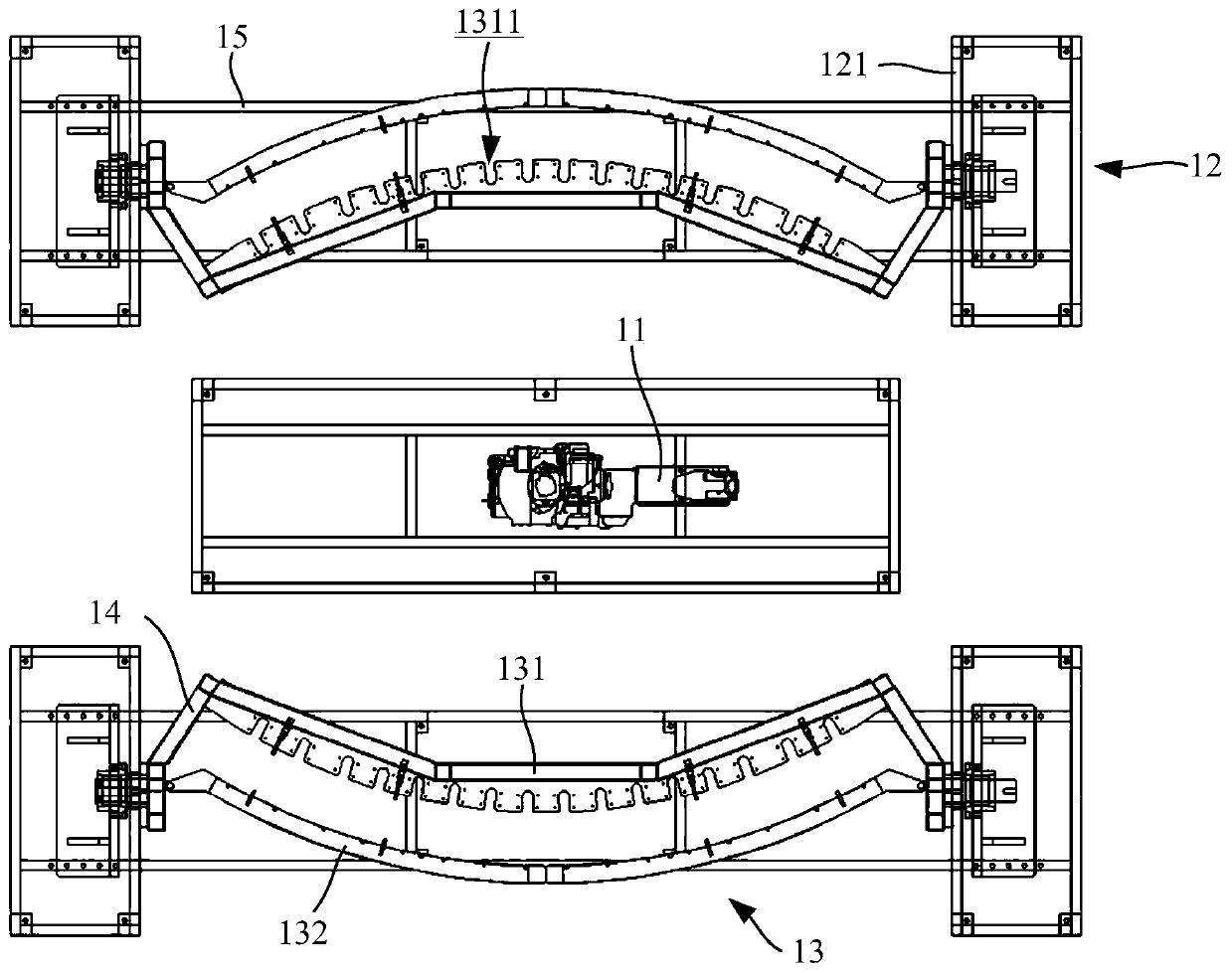

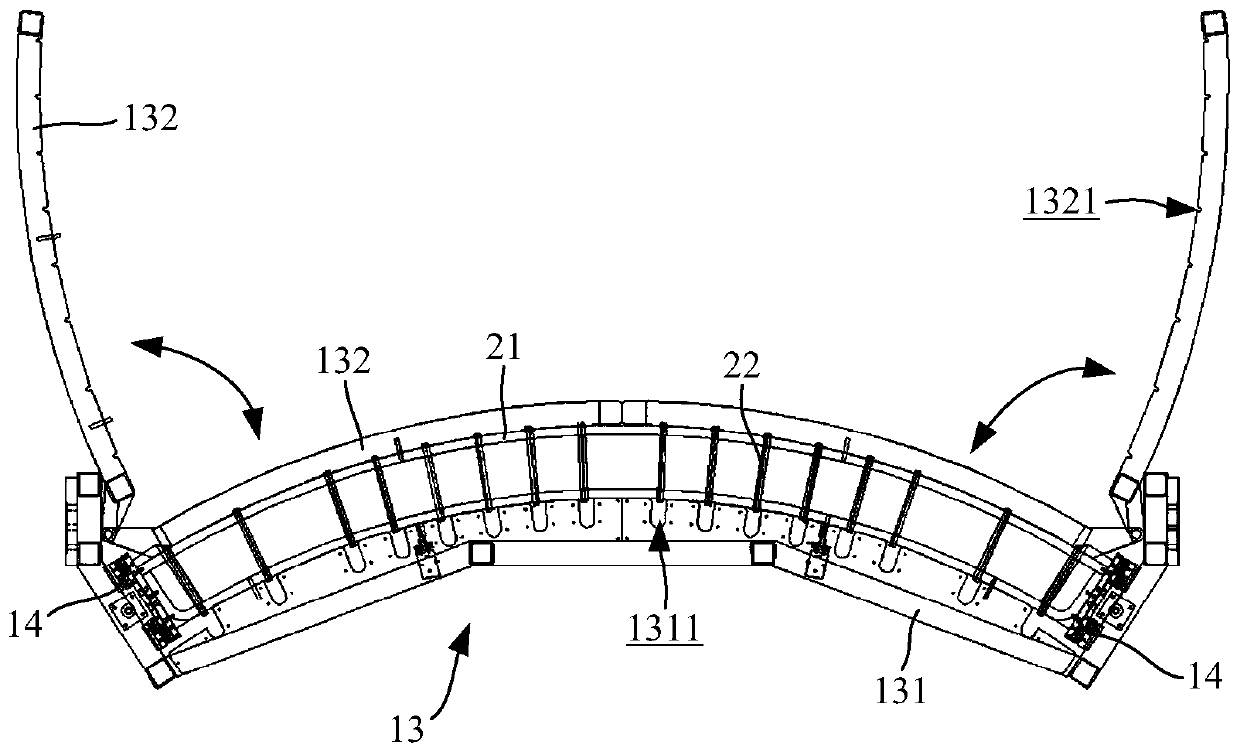

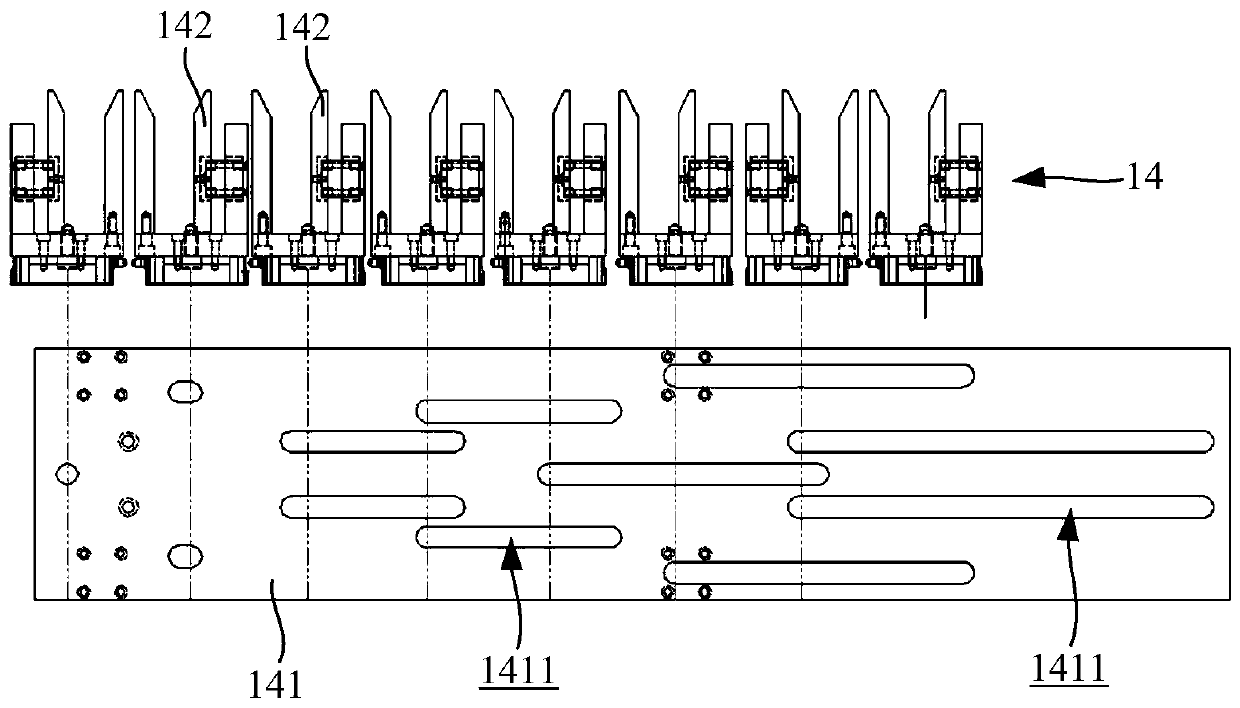

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The present invention adopts an automatic welding device for the steel cage of the segment, fixes several mesh units on the fixed frame through the clamping parts, and sets a number of stirrups corresponding to the positioning grooves to hoop several mesh units, and then adjusts the clamping parts The position of the mesh unit has a set distance, and the fixed frame is rotated to weld and connect several mesh units and stirrups with the welding manipulator to form a segment steel cage. The rotating fixed frame enables the welding manipulator to weld from multiple directions Each node makes the connection between the mesh unit and the stirrup more firm, solves the problem of unstable welding quality of the segmental reinforcement cage, uses the automatic welding system to weld the segmental reinforcement cage, reduces the amount of labor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com