A portable fully automatic metal pipe welding equipment

A technology for metal pipes and welding equipment, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as uneven technical level of welding technicians, burns, and affecting welding quality, so as to solve the problems of unstable welding quality, Cost saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

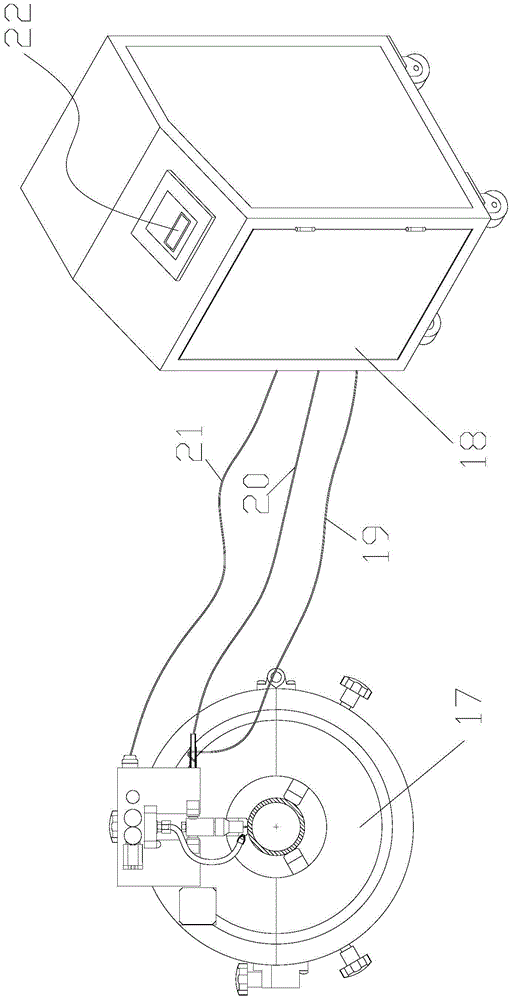

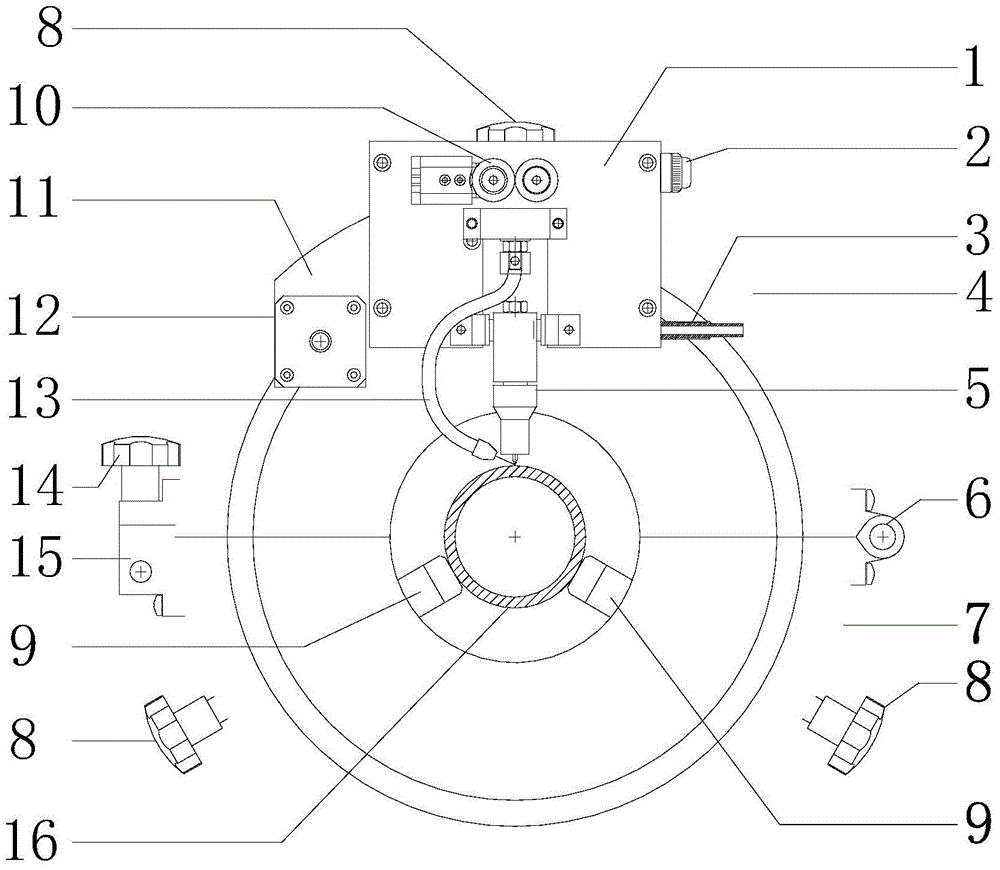

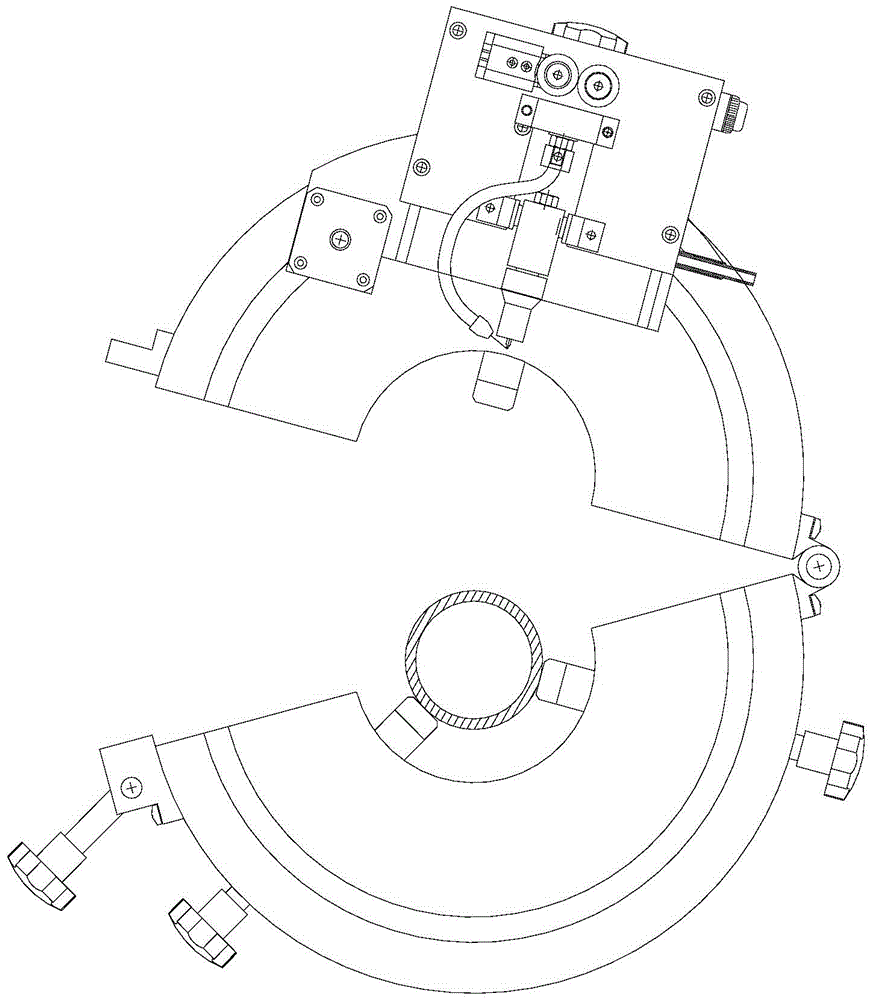

[0017] see figure 1 , figure 2 and image 3 , a portable fully automatic metal pipeline welding equipment of the present invention, comprising a welding control system 18 and a welding execution system 17, a welding power line 19, an air pipeline 20 and a control cable are arranged and connected between the welding control system 18 and the welding execution system 17 twenty one.

[0018] Welding control system 18 includes single-chip microcomputer (not shown in the figure), PLC (not shown in the figure) and man-machine interface 22, adopts single-chip microcomputer, cooperates with PLC and stores the standard welding parameters of all specification pipes. The welding control system 18 provides welding electric energy for the welding execution system 17 from the welding power source. The welding execution system 17 obtains the welding parameters and power from the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com