A molding device and process for rubber sponge barrel-shaped profiles

A rubber sponge and molding device technology, which is applied in the field of rubber sponge production, can solve problems such as uneven cell structure, high opening rate, and uncontrollable structure, and achieve uniform and stable cell size, simple process, and consistent product quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

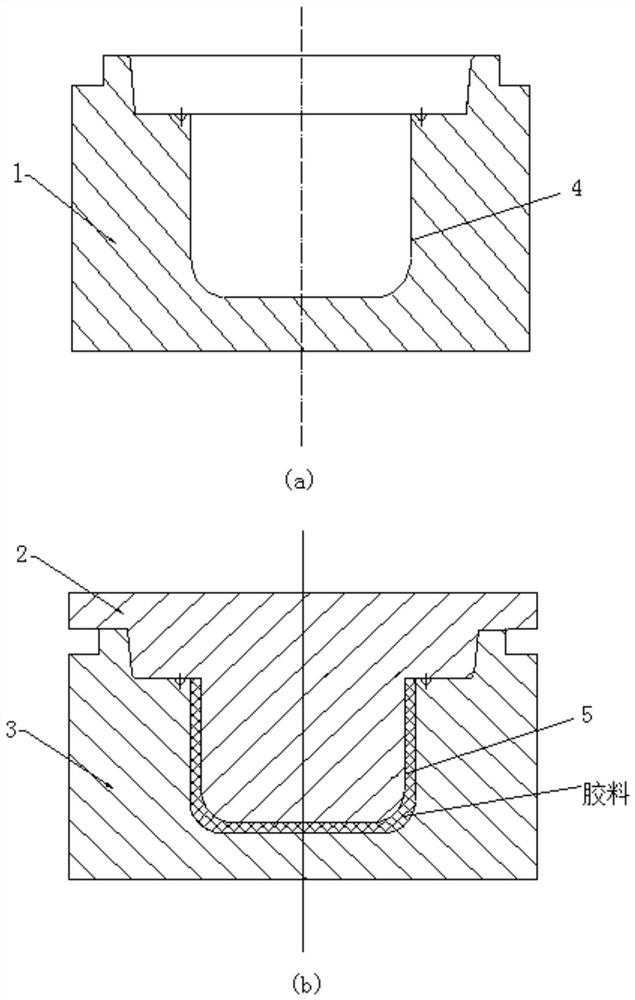

[0030] A molding device for a rubber sponge barrel-shaped profile, comprising a molding core rod 2, a shaping die 1 and a lower molding die 3, and the shaping core rod 2 is respectively matched with the top of the shaping die 1 and the lower molding die 3. Suitably, a first U-shaped barrel-shaped filling cavity 4 is arranged inside the shaping die 1 , and a second U-shaped barrel-shaped filling cavity 5 is arranged inside the lower mold 3 of the forming die.

[0031] The shape of the setting die 1 and the lower die 3 of the forming die are the same.

[0032] The size of the first U-shaped barrel-shaped filling cavity 4 of the shaping die 1 is smaller than the size of the second U-shaped barrel-shaped filling cavity 5 of the lower mold 3 according to the ratio of the foaming ratio of the rubber compound.

[0033] The shaping die 1 is divided into two longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com