Semi-finished product supporting frame for glass processing

A technology of semi-finished products and support frames, which is applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of poor screw stability, inconvenient specification adjustment, and easy corrosion of the surface, so as to achieve convenient height adjustment and ensure stability. , The effect of convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

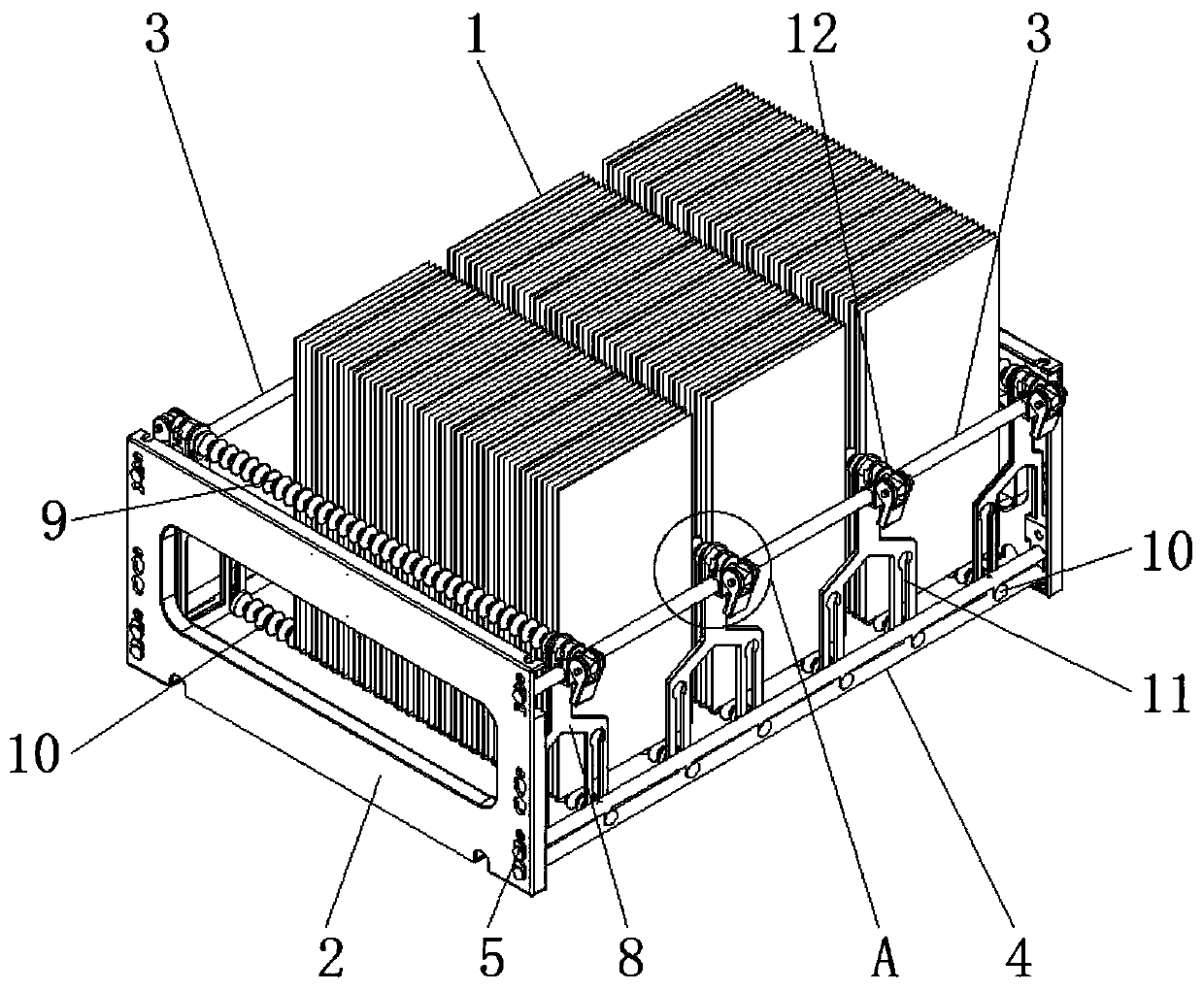

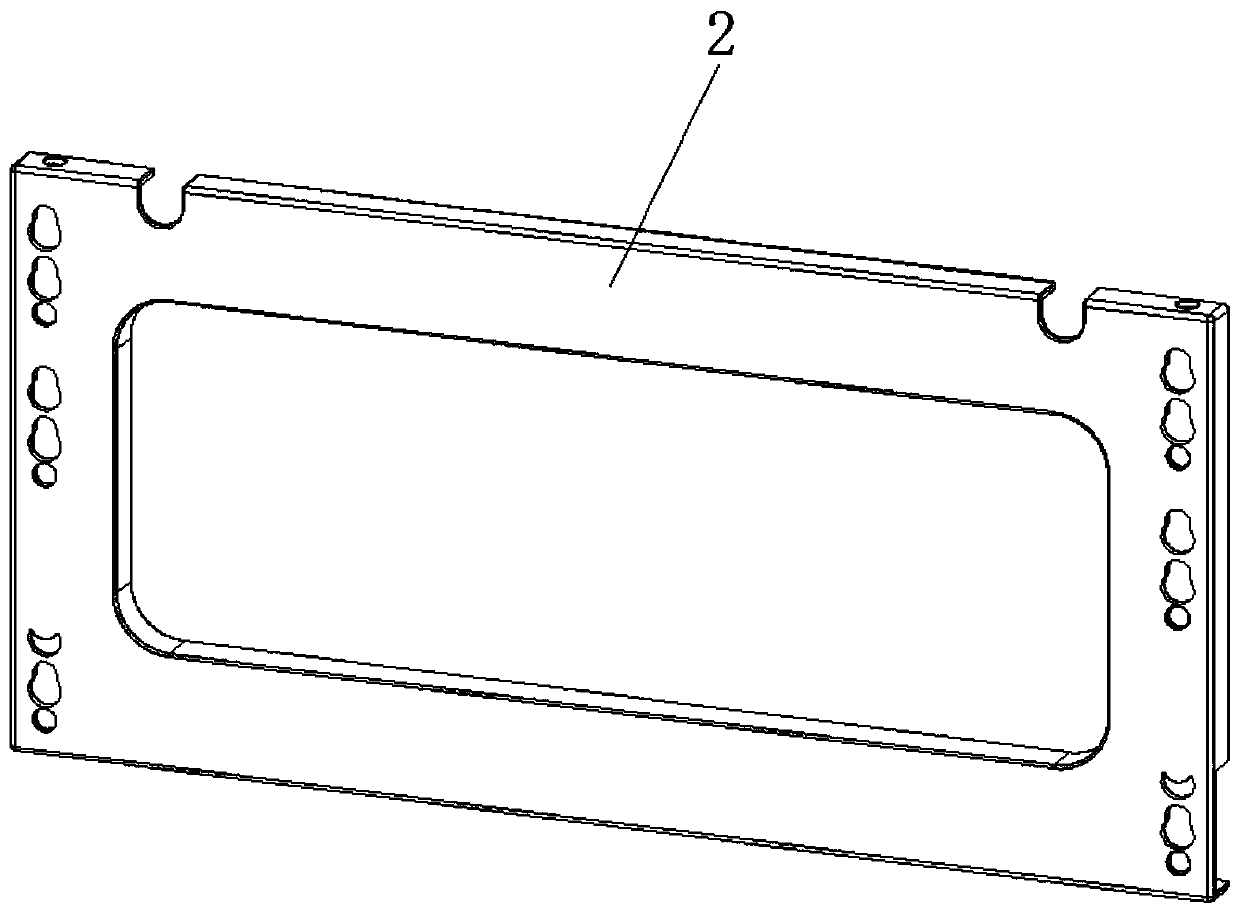

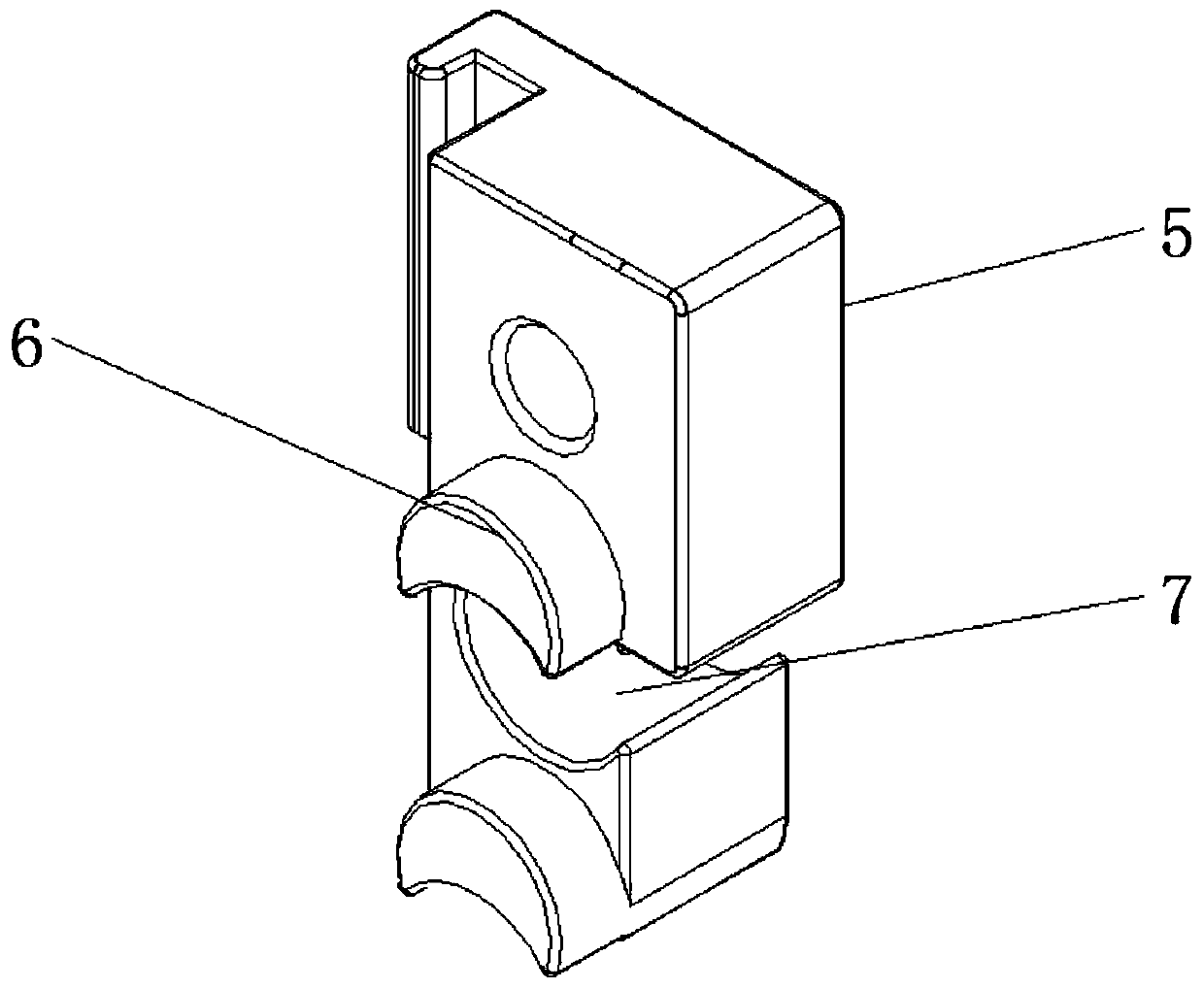

[0030] Such as Figure 1-6 , a semi-finished support frame for glass processing, including a workpiece body 1 and baffles 2, the workpiece body 1 is equally spaced between the baffles 2, and two baffles 2 are symmetrically distributed, and between the baffles 2 The first chrome-plated rod 3 and the second chrome-plated rod 4 that are horizontally distributed are provided, the connector 5 is installed on the first chrome-plated rod 3, the side of the first chrome-plated rod 3 is provided with a mounting plate 8, and the vertically distributed mounting plate 8 The top is connected with the first locating rod 9, and its bottom is connected with the second locating rod 10, the first locating rod 9 is connected with the first chrome-plated rod 3 by the fixture 12, and the first locating rod 9 and the first chrome-plated rod 3 are distributed at an angle of 90°.

[0031] The first chrome-plated rod 3 is positioned above the second chrome-plated rod 4, and the second chrome-plated r...

Embodiment 2

[0034] Such as Figure 2-3 with Figure 7-10 , a semi-finished support frame for glass processing, including a workpiece body 1 and baffles 2, the workpiece body 1 is equally spaced between the baffles 2, and two baffles 2 are symmetrically distributed, and between the baffles 2 The first chrome-plated rod 3 and the second chrome-plated rod 4 that are horizontally distributed are provided, the connector 5 is installed on the first chrome-plated rod 3, the side of the first chrome-plated rod 3 is provided with a mounting plate 8, and the vertically distributed mounting plate 8 The top is connected with the first locating rod 9, and its bottom is connected with the second locating rod 10, the first locating rod 9 is connected with the first chrome-plated rod 3 by the fixture 12, and the first locating rod 9 and the first chrome-plated rod 3 are distributed at an angle of 90°.

[0035] The first chrome-plated rod 3 is positioned above the second chrome-plated rod 4, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com