Manufacturing method and structure for improving bendability of ultrathin glass mobile phone cover plate

A technology of ultra-thin glass and its manufacturing method, which is applied in the direction of glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as high burst risk, and achieve the effects of improving product yield, saving consumption, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

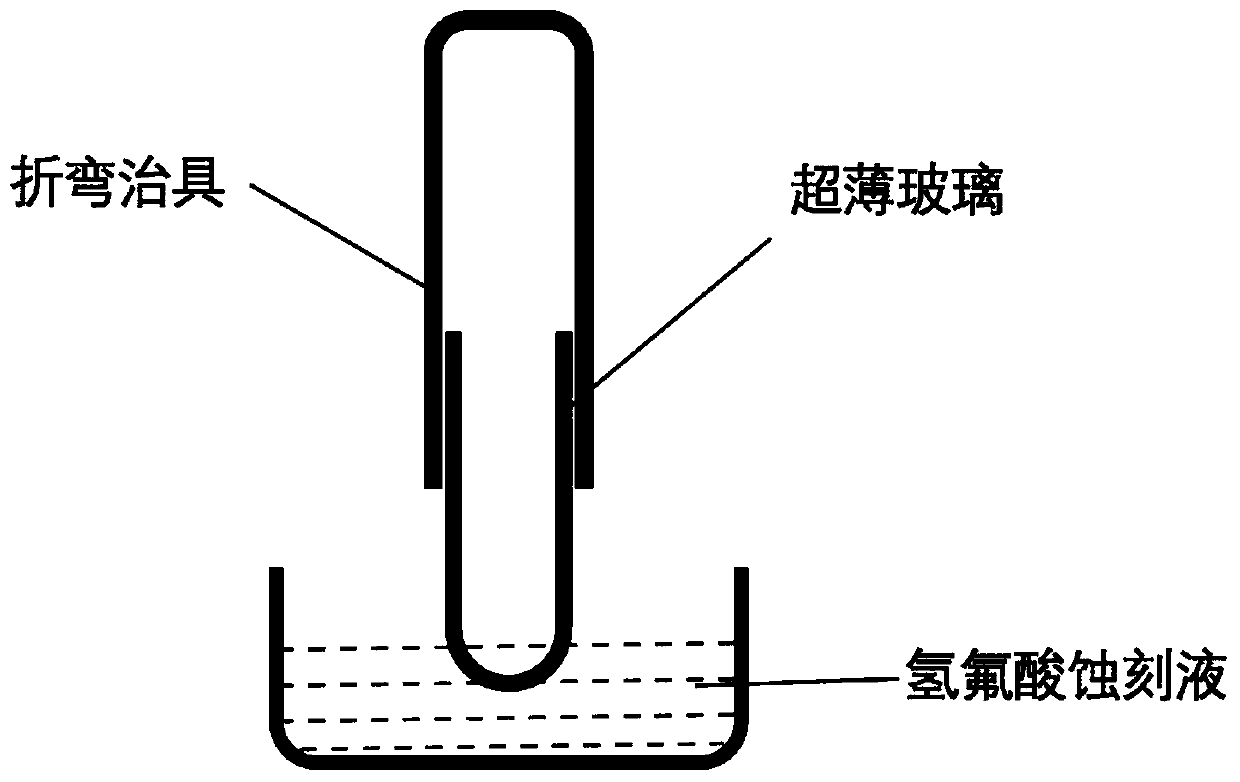

Method used

Image

Examples

Embodiment 1

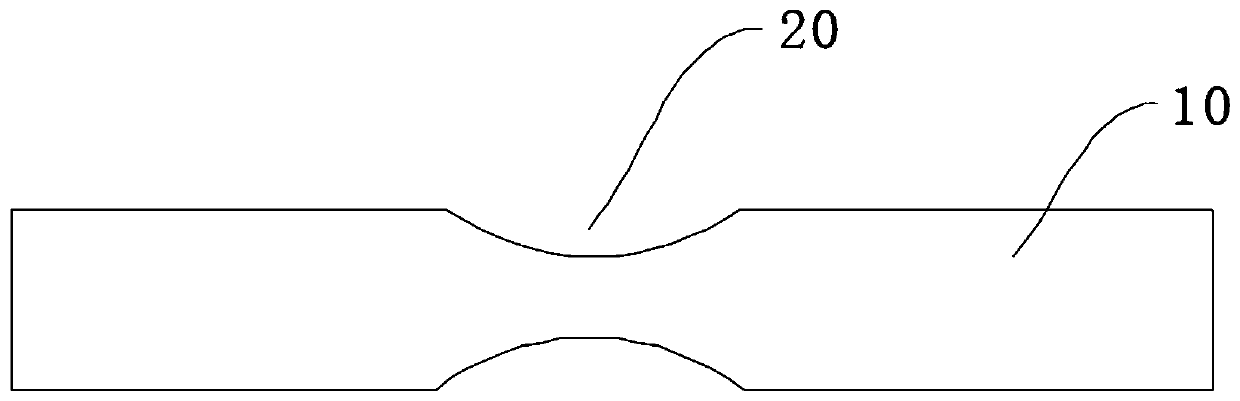

[0047] Improve the bendability structure of the ultra-thin glass mobile phone cover, the bendable structure of the ultra-thin glass mobile phone cover is made by the method of improving the bendability of the ultra-thin glass mobile phone cover, the ultra-thin glass mobile phone cover The bendable structure of the plate includes an ultra-thin glass mobile phone cover plate 10, and the upper and lower surfaces of the ultra-thin glass mobile phone cover plate 10 are provided with recessed areas 20 at the position of the bending axis.

[0048] As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 30-300 microns.

[0049] As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 100 microns.

[0050] As an optimal solution for improv...

Embodiment 2

[0053] combine image 3 As shown, the bendable structure of the ultra-thin glass mobile phone cover is improved. The bendable structure of the ultra-thin glass mobile phone cover is made by the production method to improve the bendability of the ultra-thin glass mobile phone cover. The bendable structure of the glass mobile phone cover plate includes an ultra-thin glass mobile phone cover plate 10, and the lower surface of the ultra-thin glass mobile phone cover plate 10 is provided with a recessed area 20 at the position of the bending axis.

[0054]As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 30-300 microns.

[0055] As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 100 microns.

[0056] As an optimal solution...

Embodiment 3

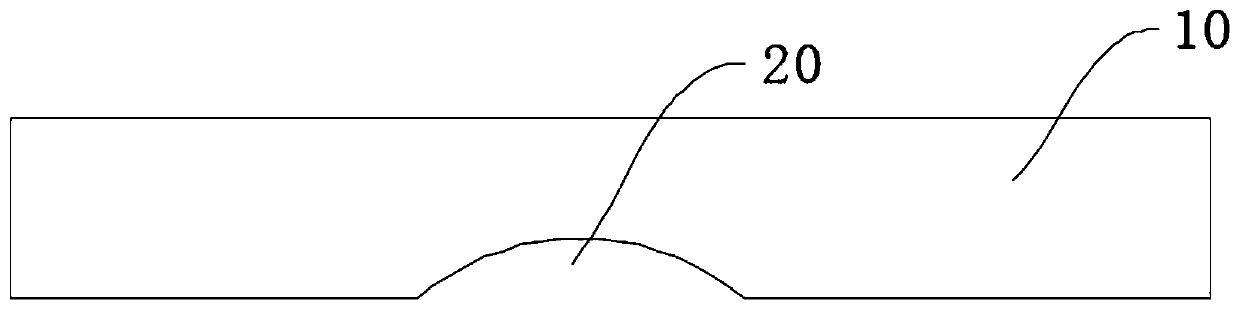

[0059] combine Figure 4 As shown, the bendable structure of the ultra-thin glass mobile phone cover is improved. The bendable structure of the ultra-thin glass mobile phone cover is made by the production method to improve the bendability of the ultra-thin glass mobile phone cover. The bendable structure of the glass mobile phone cover plate includes an ultra-thin glass mobile phone cover plate 10, and the upper surface of the ultra-thin glass mobile phone cover plate 10 is provided with a recessed area 20 at the position of the bending axis.

[0060] As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 30-300 microns.

[0061] As an optimal solution for improving the bendability structure of the ultra-thin glass mobile phone cover plate, the thickness of the ultra-thin glass mobile phone cover plate 10 is 100 microns.

[0062] As an optimal soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com