A kind of cross-linked polyethylene and its preparation method and application

A technology of cross-linked polyethylene and polyethylene, which is applied in the field of cross-linked polyethylene and its preparation, can solve problems such as unrecyclable processing, expensive equipment, and environmental pollution, so as to improve physical and mechanical properties, improve mechanical properties, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

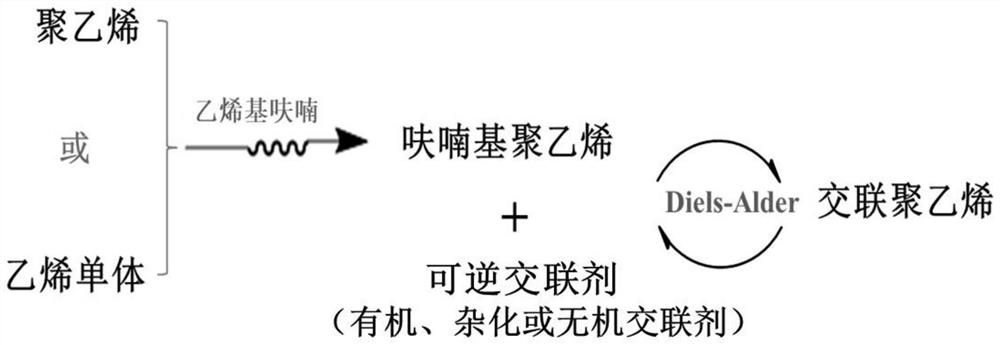

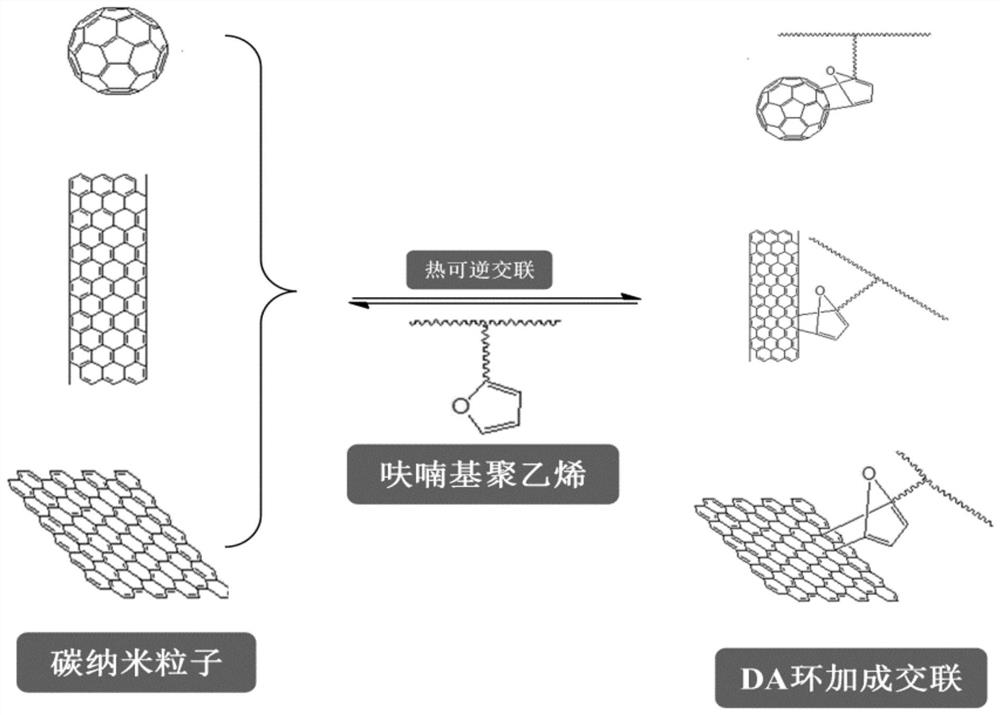

[0056] Preparation Example 1: The preparation of furyl-modified polyethylene specifically includes the following steps:

[0057] In the low-pressure, medium-pressure and high-pressure process of the slurry method, gas phase method or solution method of polyethylene production, ethylene and vinyl furan are added at the same time for polymerization to obtain furan-based copolymerized polyethylene; or the initiator (DCP or BPO ), polyethylene, vinyl furan, stabilizer, etc. are added to the twin-screw extruder together, and polyethylene and vinyl furan monomers generate active free radicals under the action of the initiator, so that furan groups are grafted to polyethylene molecules on the chain to obtain furyl grafted polyethylene;

[0058] Described vinyl furan includes 2-vinyl furan, 2-(2-nitrovinyl) furan, 5-(2-methoxycarbonyl vinyl furan)-2 carboxymethyl ester, [5-[2- (5-methylfuran-2-yl)vinyl]furan-2-yl]methanol and its derivatives; the polyethylene includes but not high-de...

preparation example 2

[0059] Preparation example 2: the preparation method of bismaleimide crosslinking agent specifically comprises:

[0060] a1. Add maleic anhydride and furan monomers in equimolar amounts to a polar aprotic solvent, and react for 4 to 20 hours at 20 to 90° C., the molar equivalent ratio of maleic anhydride to the polar aprotic solvent is 1:1~1:1000; the polar aprotic solvent includes one of DMF, NMP, DMSO, and DMAC;

[0061] b1. Add 0.5 molar equivalent of diamine monomer into the above-mentioned polar aprotic solvent, and add it dropwise into the above-mentioned solution through a peristaltic pump, and stir the mixed solution at 50-90°C for 6-24 hours; wherein diamine and polar The molar equivalent ratio of the solvent is 1:1~1:1000;

[0062] c1. Add 0.1-10.0 molar equivalents of acetic anhydride, 0.005-1.0 millimole equivalents of sodium acetate, and 0.005-1.0 molar equivalents of triethylamine, and continue the reaction for 3-12 hours;

[0063] d1. The mixture is dried by r...

preparation example 3

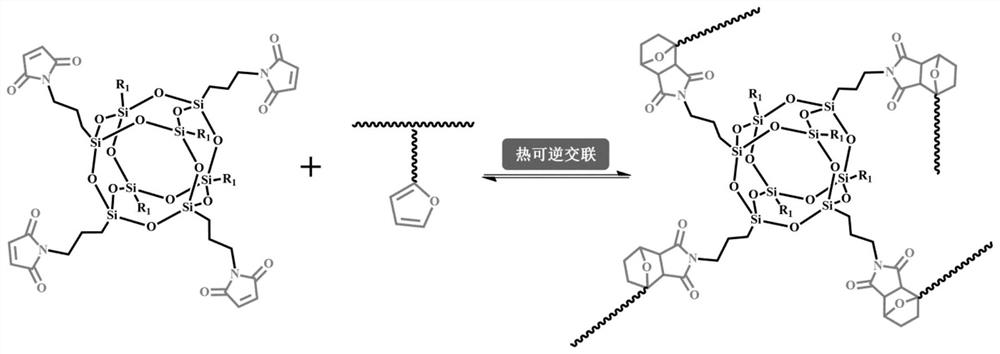

[0065] Preparation Example 3: The preparation method of maleimide-modified POSS nanoparticles (n=2~8) specifically includes:

[0066] a2, 8~10 molar equivalents of maleic anhydride are dissolved in an appropriate amount of methanol to form a homogeneous solution;

[0067] b2, 1 molar equivalent of POSS hydrochloride and 0.1 to 1.0 molar equivalent of triethylamine are dissolved in an appropriate amount of methanol, and added dropwise to the above-mentioned filtrate;

[0068] c2. Continue to stir at 25-60°C for 3-24 hours after the dropwise addition, filter and dry to obtain a white powder;

[0069] d2. Add 0.7 millimole equivalents of the above powder, 0.001-1.0 molar equivalents of acetic anhydride, 0.005-0.1 molar equivalents of sodium acetate, and 0.005-0.1 molar equivalents of triethylamine into 0.1-10.0 molar equivalents of DMF, 60 React at ~150°C for 6-24 hours, remove the solvent by rotary evaporation, wash the product 3-5 times, and dry to obtain maleimide-modified PO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com