Substrate for compressor shell and production method of substrate

A production method and compressor technology, applied in the iron and steel field, can solve problems such as lack of substrates for compressor shells, and achieve good market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

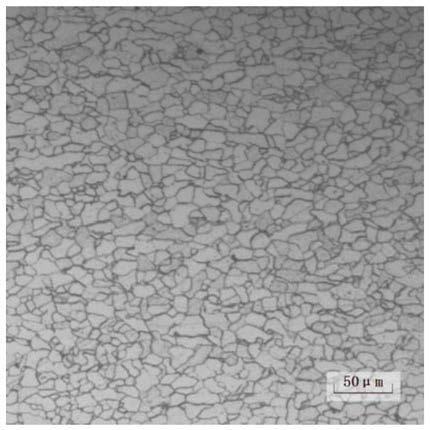

Image

Examples

Embodiment 1

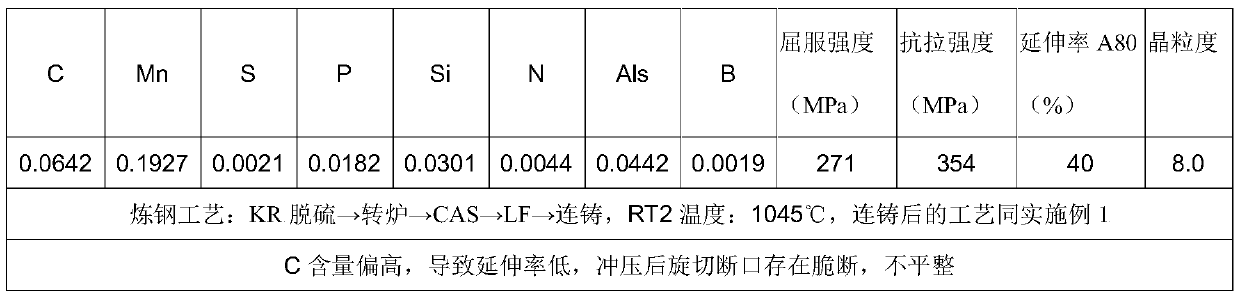

[0033] A substrate for a compressor housing, the chemical composition and weight percentage of which are shown in Table 1.

[0034] Table 1

[0035] C mn S P Si N als B 0.044 0.2118 0.0051 0.0144 0.0079 0.003 0.0367 0.0018 The balance is Fe and unavoidable impurities

[0036] The production method of the substrate for the compressor shell comprises the following steps:

[0037] (1) Desulfurization treatment of molten iron → converter smelting → argon blowing → LF → RH furnace refining to obtain molten steel with the composition described in Table 1, and then continuously cast slabs;

[0038] (2) Hot rolling process: heat the slab to 1200°C for rough rolling, the rough rolling adopts 3+3 mode, and RT1 rough rolling 3 passes, descaling in single and double passes; RT2 rough rolling 3 passes , using single and double pass descaling, RT2 temperature is controlled at 1025°C; final rolling temperature is 877°C, cooled to 643°C for coiling.

...

Embodiment 2

[0043] A substrate for a compressor shell, the chemical composition and weight percentage of which are shown in Table 2.

[0044] Table 2

[0045] C mn S P Si N als B 0.0401 0.1843 0.0056 0.0148 0.0072 0.002 0.0218 0.0016 The balance is Fe and unavoidable impurities

[0046] The production method of the substrate for the compressor shell comprises the following steps:

[0047] (1) hot metal desulfurization treatment → converter smelting → argon blowing → LF → RH furnace refining, obtain the molten steel of the composition described in Table 2, and then continuously cast slabs;

[0048] (2) Hot rolling process: heat the slab to 1204°C for rough rolling, the rough rolling adopts 3+3 mode, and RT1 rough rolling 3 passes, descaling in single and double passes; RT2 rough rolling 3 passes , using single and double pass descaling, RT2 temperature is controlled at 1035°C; final rolling temperature is 880°C, cooled to 641°C for coiling.

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com